Supercapacitor, electrodes therefor, and method for preparing active material of electrodes

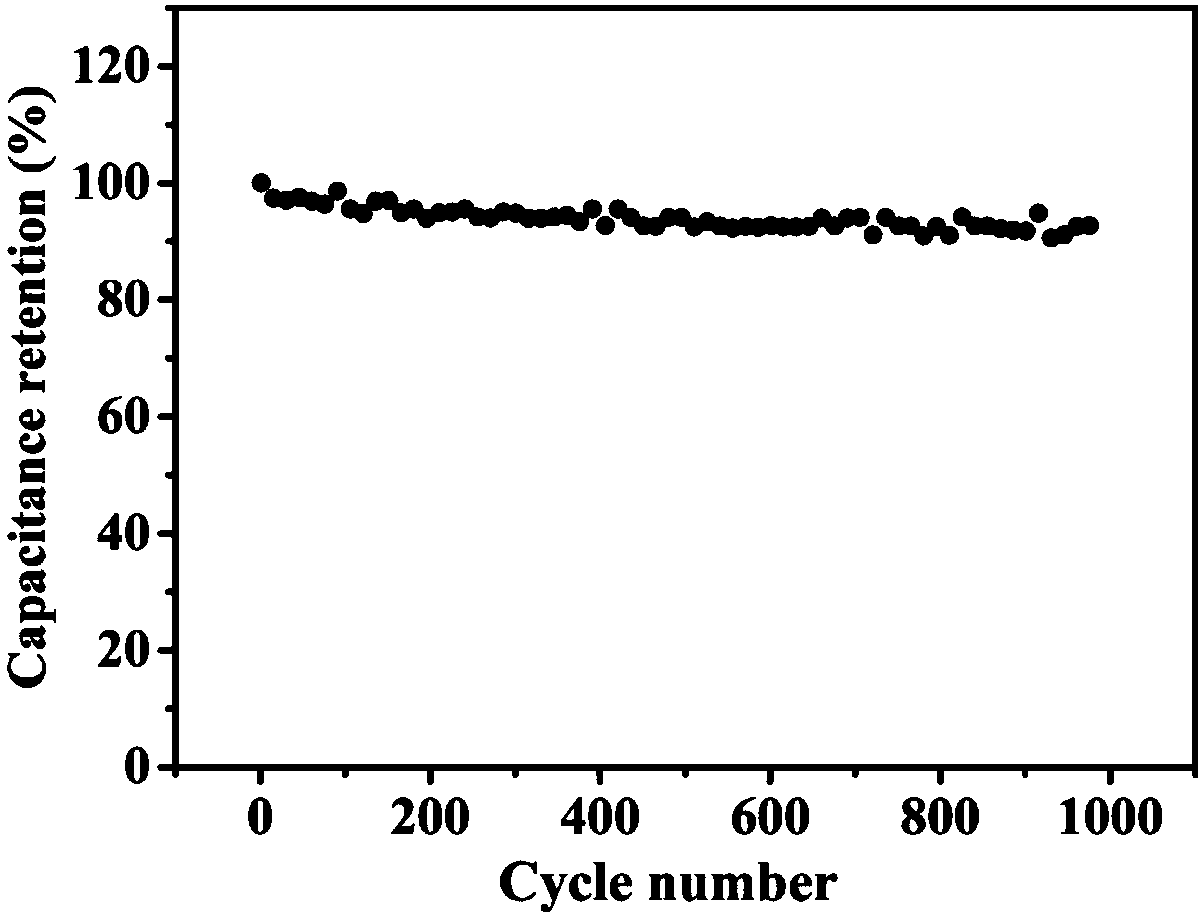

An active material and electrode technology, which is applied in the field of preparation of supercapacitors, electrodes and active materials thereof, can solve the problems of slow redox reaction rate, ineffective active area, and increase the burden on electrodes, and avoid poor thermal conductivity and good circulation. properties, and the effect of promoting redox reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of preparation method of tubular copper hydroxide active material is characterized in that, comprises the steps:

[0031] S1. Choose a 0.1mm thick copper sheet with a size of 2cm×2cm.

[0032] S2. Soak the copper sheet in dilute hydrochloric acid and deionized water in sequence, so as to clean the surface of the copper sheet.

[0033] S3, then soak the cleaned copper sheet in 20mL of NaOH (concentration is 1mol / mL) and (NH 4 ) 2 S 2 o 8 (concentration of 0.5mol / mL) in the mixed solution, soak for 5min until the color of the copper sheet changes from orange to blue.

[0034] S4, take out the copper sheet, and wash it several times with water and ethanol.

[0035] S5, the copper sheet is placed in a vacuum drying oven for drying, thereby obtaining a tubular copper hydroxide active material grown on the surface of the copper sheet, which can be directly used as a pseudocapacitive integrated electrode material and used for Supercapacitor electrodes.

[0036] S...

Embodiment 2

[0039] A kind of preparation method of tubular copper hydroxide active material is characterized in that, comprises the steps:

[0040] S1. Choose a 0.2mm thick copper sheet with a size of 2cm×2cm.

[0041] S2. Soak the copper sheet in dilute hydrochloric acid and deionized water in sequence.

[0042] S3, then soak the cleaned copper sheet in 20mL of NaOH (concentration is 0.5mol / mL) and (NH 4 ) 2 S 2 o 8 (concentration of 0.5mol / mL) mixed solution; soak for 5min until the color of the copper sheet changes from orange to blue.

[0043] S4, take out the copper sheet, and wash it several times with water and ethanol.

[0044] S5, the copper sheet is placed in a vacuum drying oven for drying, thereby obtaining a tubular copper hydroxide active material grown on the surface of the copper sheet, which can be directly used as a pseudocapacitive integrated electrode material and used for Supercapacitor electrodes.

Embodiment 3

[0046] A method for preparing a tubular copper hydroxide active material is characterized by comprising the following steps.

[0047] S1. Choose a 0.2mm thick copper sheet with a size of 2cm×2cm.

[0048] S2. Soak the copper sheet in dilute hydrochloric acid and deionized water in sequence.

[0049] S3, then soak the cleaned copper sheet in 20mL of NaOH (concentration is 0.5mol / mL) and (NH 4 ) 2 S 2 o 8 (concentration of 0.5mol / mL) in the mixed solution, soak for 10min until the color of the copper sheet changes from orange to blue.

[0050] S4, take out the copper sheet, and wash it several times with water and ethanol.

[0051] S5, the copper sheet is placed in a vacuum drying oven for drying, thereby obtaining a tubular copper hydroxide active material grown on the surface of the copper sheet, which can be directly used as a pseudocapacitive integrated electrode material and used for Supercapacitor electrodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com