Conductive material modified composite lithium-rich positive electrode and preparation method and application thereof

A technology of conductive materials and lithium-rich cathode materials, applied in electrode manufacturing, positive electrodes, battery electrodes, etc., can solve problems such as uneven material mixing and large particle size, achieve excellent rate performance, stable chemical properties, and improve rate performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

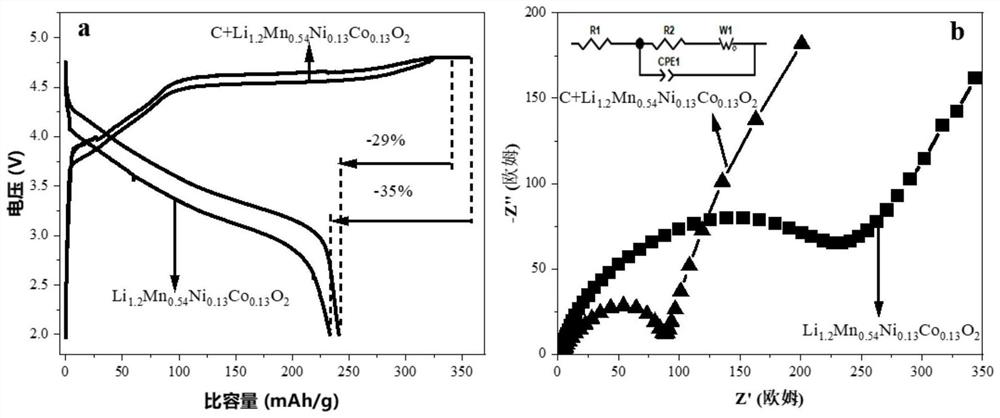

[0031] This example provides a carbon-modified lithium-rich manganese-based (Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 ) composite lithium-rich cathode and a preparation method thereof.

[0032] Carbon-modified lithium-rich manganese-based (Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 ) The preparation method of the composite lithium-rich positive electrode is: using a high-purity carbon target material and a lithium-rich manganese base (Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 ) powder target as the deposition source, co-deposition on aluminum foil, the target base distance is 80mm; at 1.0×10 -2 Carbon-modified lithium-rich manganese (Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 ) composite lithium-rich positive electrode, during deposition, keep the substrate at 550°C, and anneal at 500°C for 2 hours after deposition.

Embodiment 2

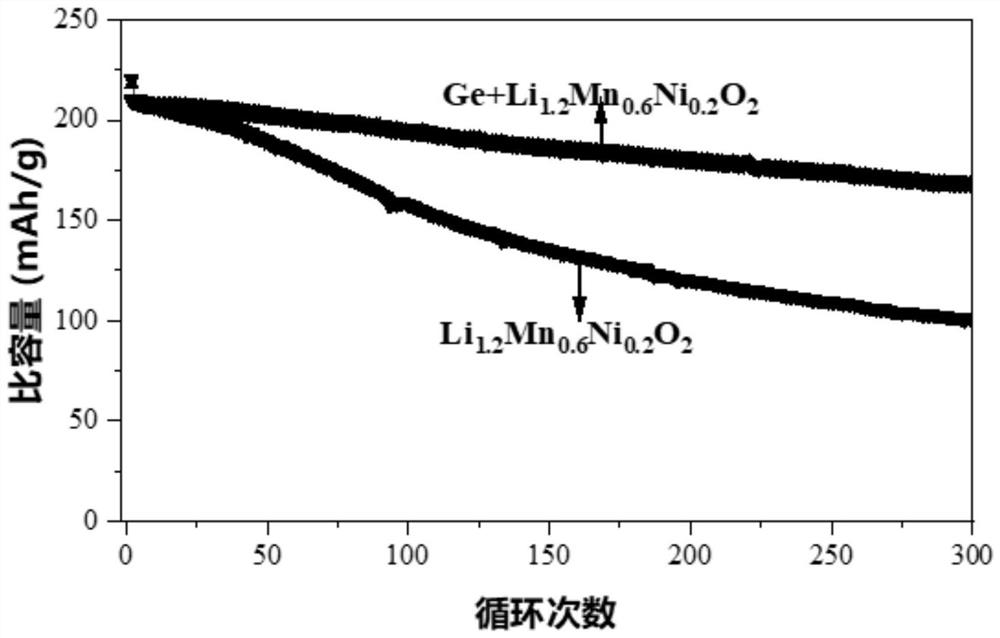

[0034] This embodiment provides germanium-modified lithium-rich manganese-based (Li 1.2 mn 0.6 Ni 0.2 o 2 ) composite lithium-rich cathode and a preparation method thereof.

[0035] Ge-modified lithium-rich manganese-based (Li 1.2 mn 0.6 Ni 0.2 o 2 ) The preparation method of the composite lithium-rich positive electrode is: using a high-purity germanium target material and a lithium-rich manganese base (Li 1.2 mn 0.6 Ni 0.2 o 2 ) powder target as the deposition source, co-deposition on aluminum foil, the target base distance is 60mm, at 1.0×10 -2 Ge-modified lithium-rich manganese (Li 1.2 mn 0.6 Ni 0.2 o 2 ) composite solid positive electrode, during the deposition, the substrate is kept at 450°C, and annealed at 500°C for 2 hours after the deposition is completed.

Embodiment 3

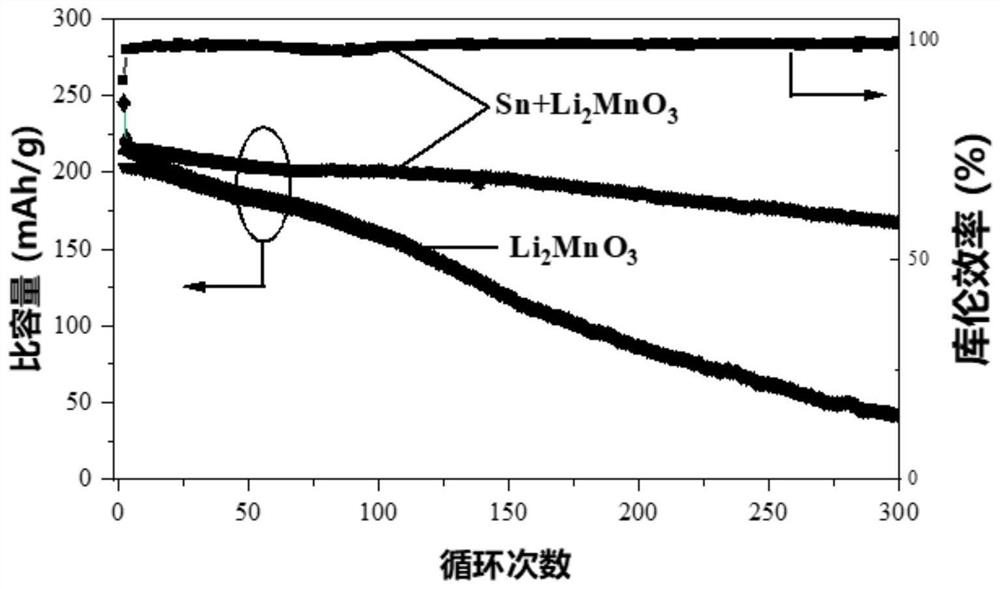

[0037] This example provides a tin-modified lithium-rich manganese-based (Li 2 MnO 3 ) composite solid positive electrode and its preparation method.

[0038] Tin-modified lithium-rich manganese-based (Li 2 MnO 3 ) The preparation method of the composite solid positive electrode is as follows: high-purity tin target material and lithium-rich manganese-based powder target material are used as deposition sources, co-deposited on aluminum foil, the target-base distance is 70mm, at 1.0×10 -2 Sn-modified lithium-rich manganese (Li-rich manganese-based (Li 2 MnO 3) composite solid positive electrode, during the deposition, the substrate is kept at 300°C, and annealed at 400°C for 1 hour after the deposition is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com