Series aluminum electrolytic capacitor element pre-packaging online charging recovery measurement and sorting method

An aluminum electrolytic capacitor, charging recovery technology, applied in the direction of electrolytic capacitors, capacitors, capacitor manufacturing, etc., can solve the problems of long assembly time, poor product performance, complex process, etc., to reduce material consumption, damage and large leakage current, process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

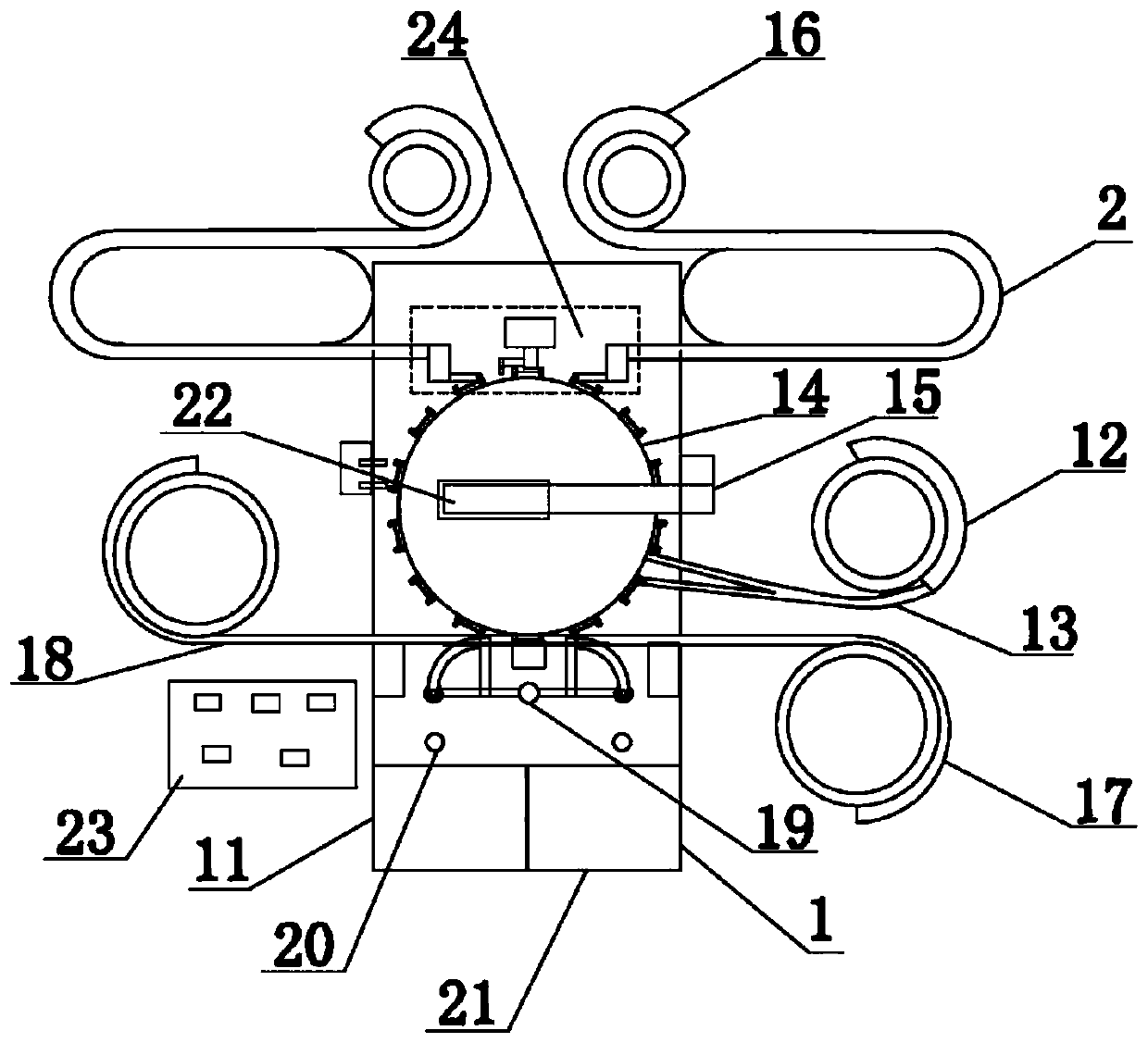

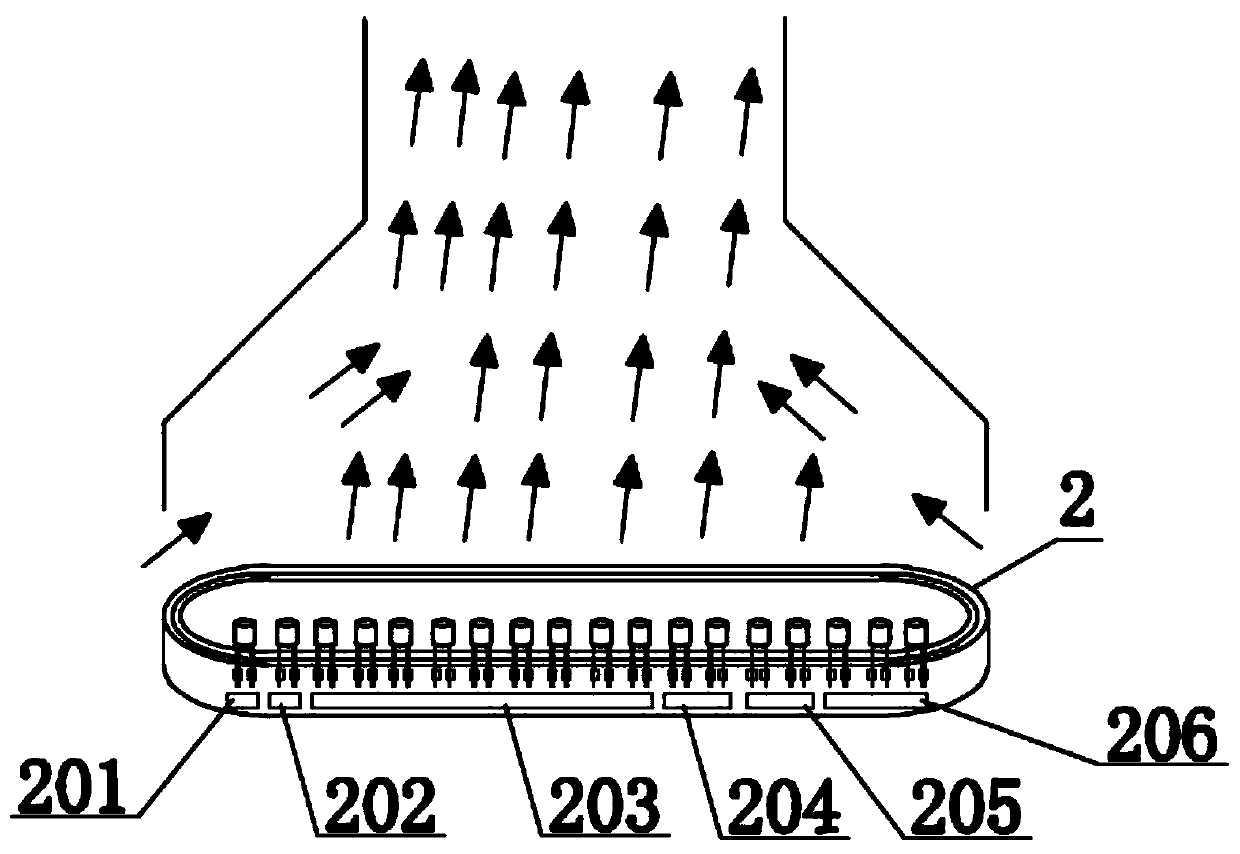

[0036] Such as figure 1 , figure 2 As shown, the sorting method for on-line charge recovery measurement before the element packaging of a series of aluminum electrolytic capacitors includes the following steps:

[0037] (1) There is a charging test sorting and activating oxide film recovery device connected between the element vibrating plate and the element feeding mechanism. After the element immersed in electrolysis is charged, the oxide film is immediately repaired. When the product equipment is connected to the high-speed assembly equipment , when the elements in the process of impregnating the electrolyte, they are automatically charged separately before the assembly equipment is assembled, so as to realize the repair procedure of the oxide film of the capacitor element in advance;

[0038] (2) After the electrolyte and the elements are infi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com