Defective metal oxide/porous carbon nanocomposite material and its preparation method and application

A technology of composite materials and oxides, applied in the direction of non-aqueous electrolyte batteries, structural parts, electrical components, etc., can solve the problem of low utilization rate of active materials, and achieve the effects of efficient use of cycle life, accelerated industrialization, and high cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention also discloses a preparation method of the above-mentioned defective metal oxide / porous nano carbon composite material, which comprises the following steps:

[0039] In step S1, a nanocarbonaceous aqueous solution is prepared.

[0040] Specifically, the concentration of the nanocarbonaceous aqueous solution does not exceed 2 mg / mL, and the solute nanocarbonaceous material can be at least one of oxidized carbon nanotubes and derivatives thereof, graphene oxide, and carbon nanofibers. It should be noted that, if there are at least two types of solute nanocarbons, the above-mentioned concentration refers to the total concentration.

[0041] Generally speaking, a relatively high-concentration nano-carbonaceous stock solution can be prepared first, then diluted with ultrapure water, and effectively sonicated for about 30 minutes using a cell sonicator to form the above-mentioned low-concentration nano-carbonaceous aqueous solution.

[0042] In order to make th...

Embodiment 1

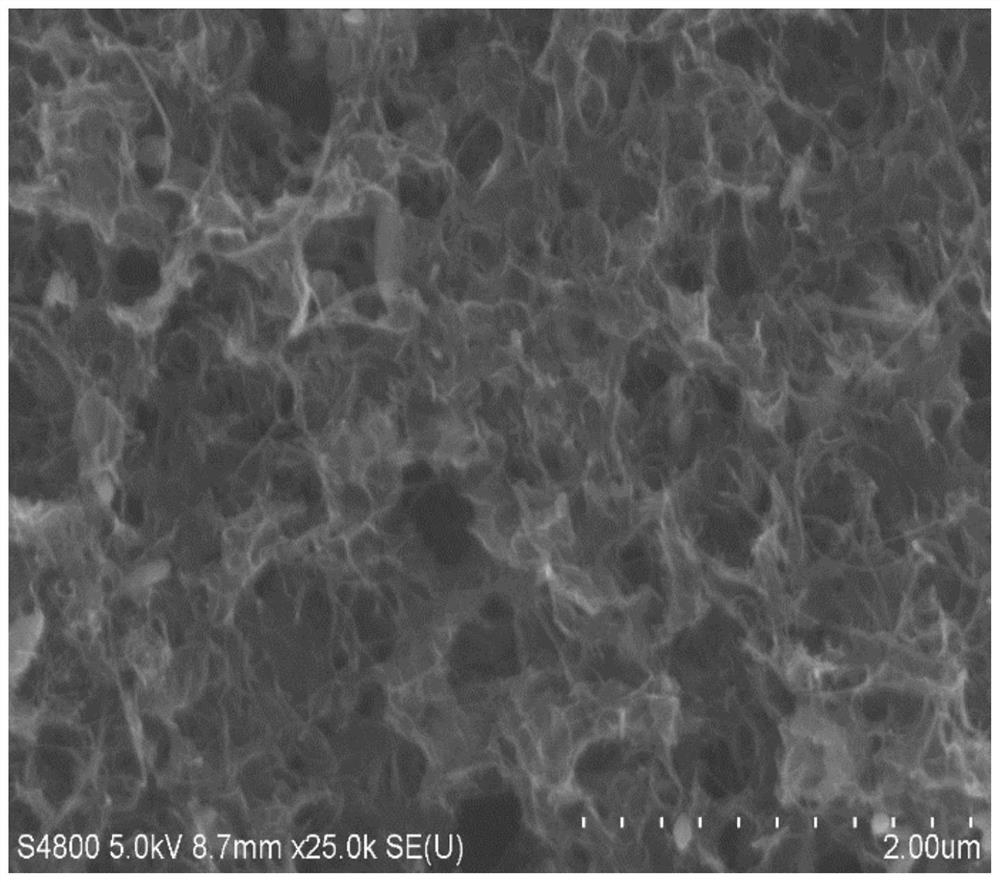

[0053] First, a certain amount of prepared carbonaceous nano-stock solution with a concentration of 7.5 mg / mL was added, diluted with ultrapure water, and effectively sonicated for about 30 min with a cell sonicator to obtain a carbonaceous nano-water solution with a concentration of 1 mg / mL.

[0054] In this embodiment, the nano carbonaceous stock solution is specifically a graphene oxide stock solution.

[0055] Secondly, adding a sulfur source precursor, a nitrogen source precursor and a metal ion source precursor to the nano carbonaceous aqueous solution, and uniformly dispersing to obtain a hydrothermal reactant.

[0056] In this embodiment, the sulfur source precursor is sodium sulfide, the nitrogen source precursor is ammonia water, and the metal ion source precursor is a 10wt% ferrous acetate solution; and the mass of sulfur element in the sulfur source precursor is nanocarbonaceous 20 wt % of the mass of the nano-carbon in the aqueous solution, the mass of the nitroge...

Embodiment 2

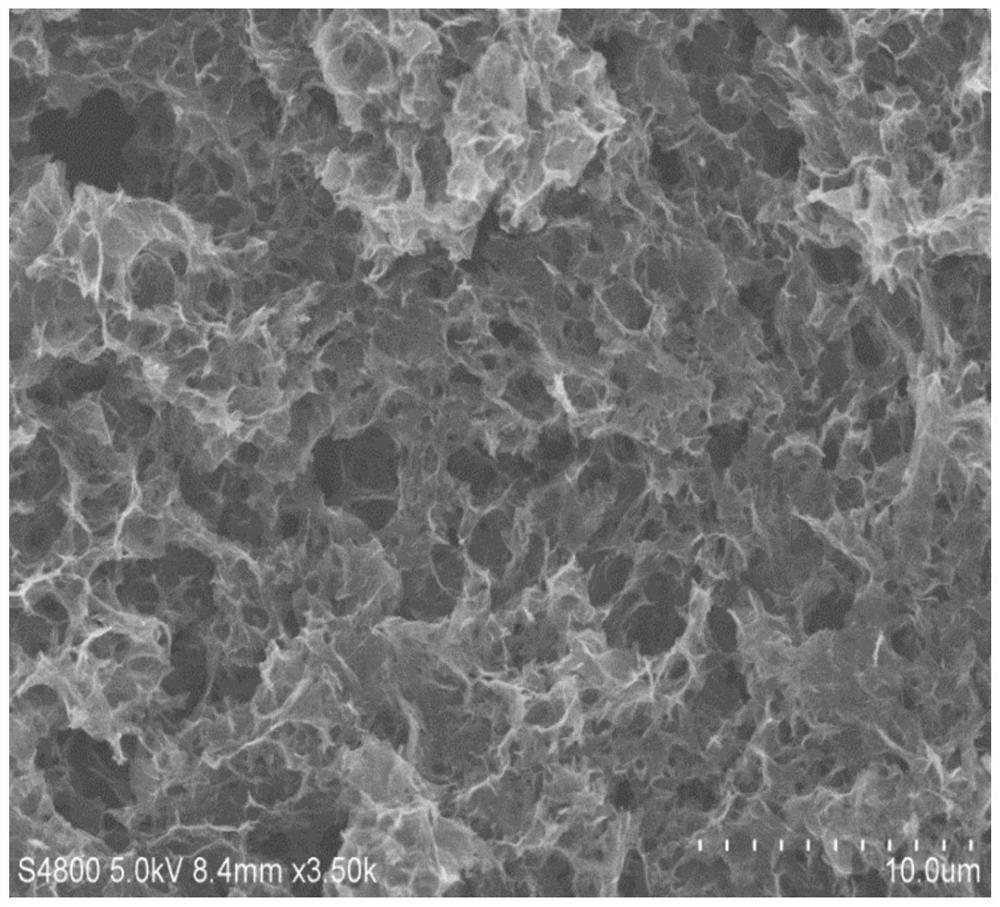

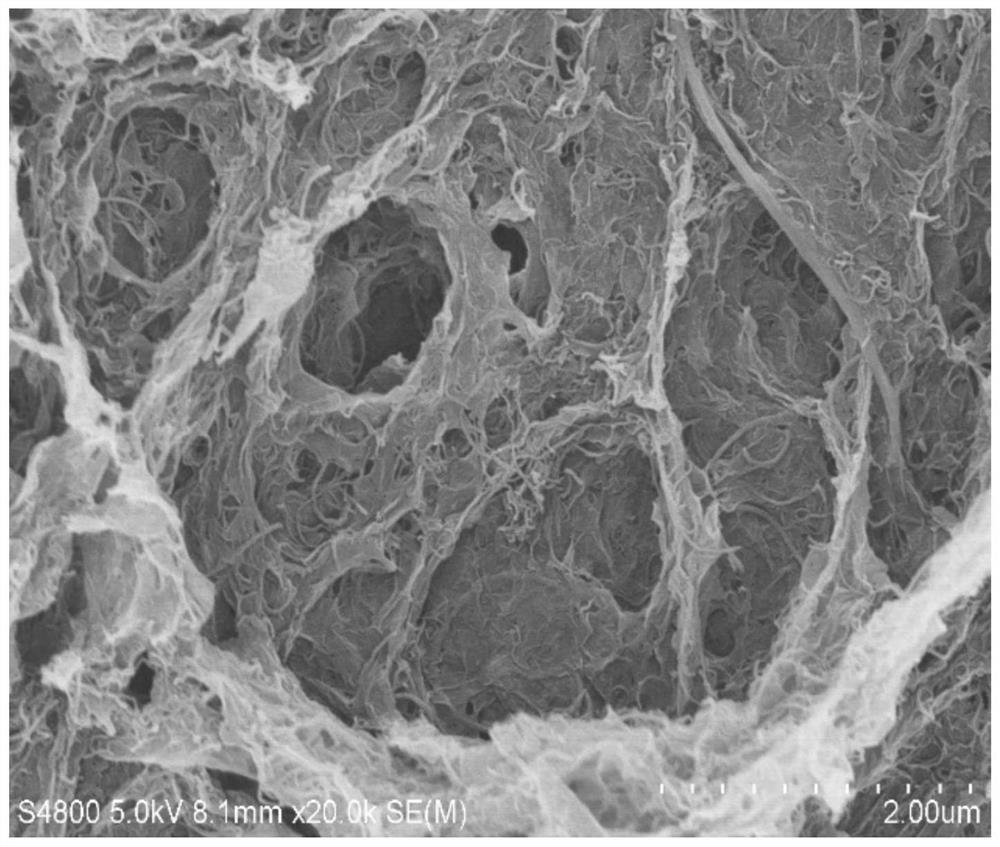

[0062] In the description of Embodiment 2, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. The difference between Example 2 and Example 1 is only that, when preparing the nano-carbonaceous aqueous solution, first preparing a graphene oxide stoste of 7.5 mg / mL with a certain concentration, then adding and graphite oxide to this graphene oxide stoste. Carbon oxide nanotubes of the same quality as ethylene, then add ultrapure water to dilute and use a cell sonicator to effectively sonicate for about 30 minutes to obtain a mixed aqueous solution of carbon oxide nanotubes and graphene oxide with a concentration of 1 mg / mL; and, control the hydrothermal The temperature is 200°C, and the hydrothermal time is 12h; for the rest, refer to Example 1 to obtain the defective metal oxide / porous nanocarbon composite material FeO of this example. x -SNGC.

[0063] That is, in the defect metal oxide / porous carbon nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com