PTC device and secondary battery having same

A technology for secondary batteries and PTC components, which is applied in secondary battery repair/maintenance, resistors with positive temperature coefficients, batteries, etc., and can solve problems such as increased volume and no PTC components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

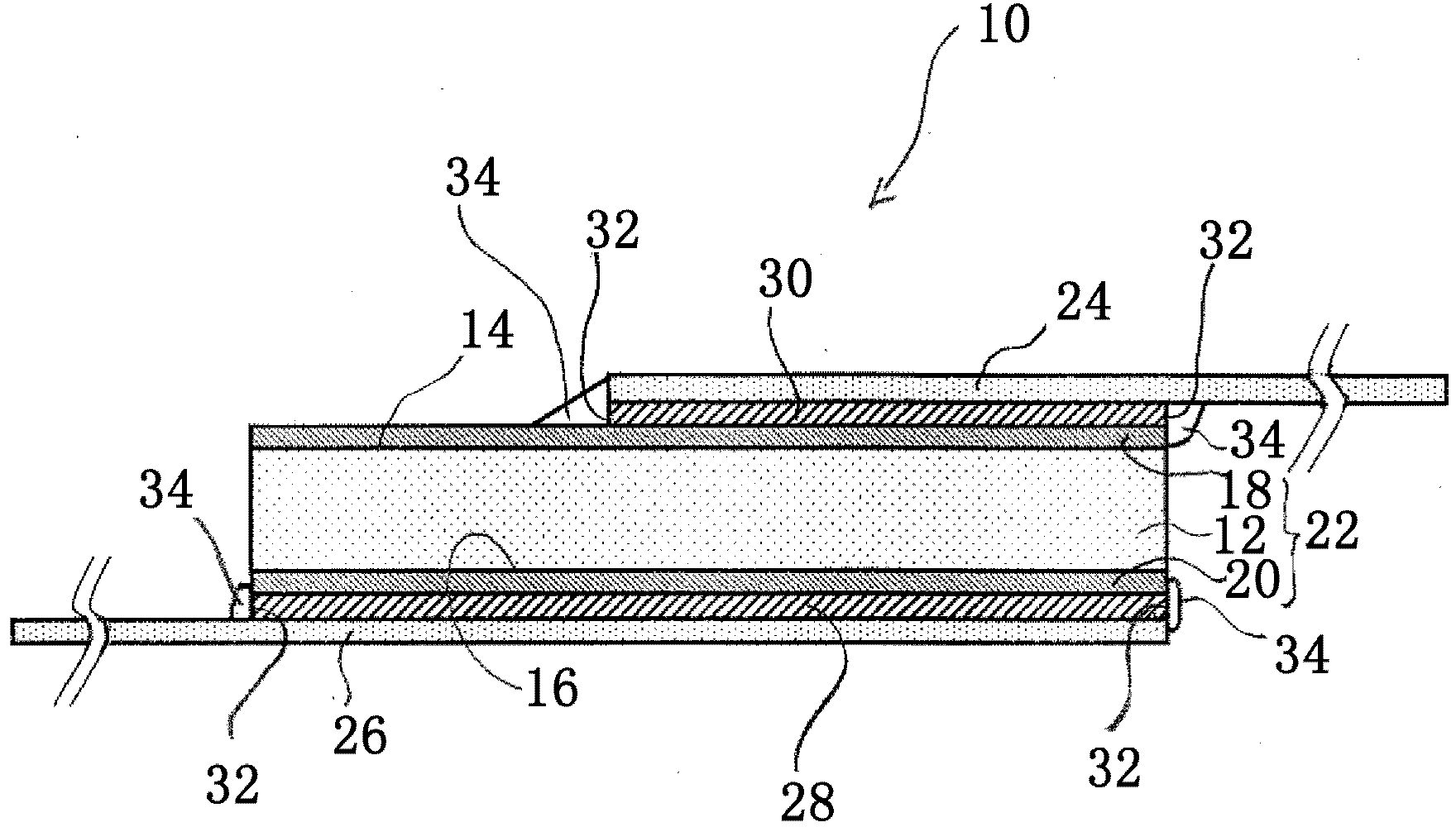

[0065] The PTC parts (assuming that the end parts of the lead wires are exposed) are thermocompression-bonded in a state sandwiched by films, thereby manufacturing Figure 4 The PTC device A of the present invention is shown. It should be noted that, during thermocompression bonding, in order to avoid force acting on the PTC component, only the film portion extending outward from the periphery of the PTC component is pressed (the lead wire portion is pressed).

[0066] The film used was a laminated film (thickness: 100 μm) of a polypropylene resin layer and a polyethylene resin layer. This film was used with the polypropylene resin layer on the outside.

[0067] It should be noted that other conditions are as follows:

[0068] PTC parts used (trade name: PolySwitch, manufactured by Tyco Electronics Japan Co., Ltd.)

[0069] Lead wire: nickel (trade name: NB201, manufactured by Neomax Corporation, thickness: 150 μm)

[0070] Conductive material: lead-free solder (alloy sold...

example 2

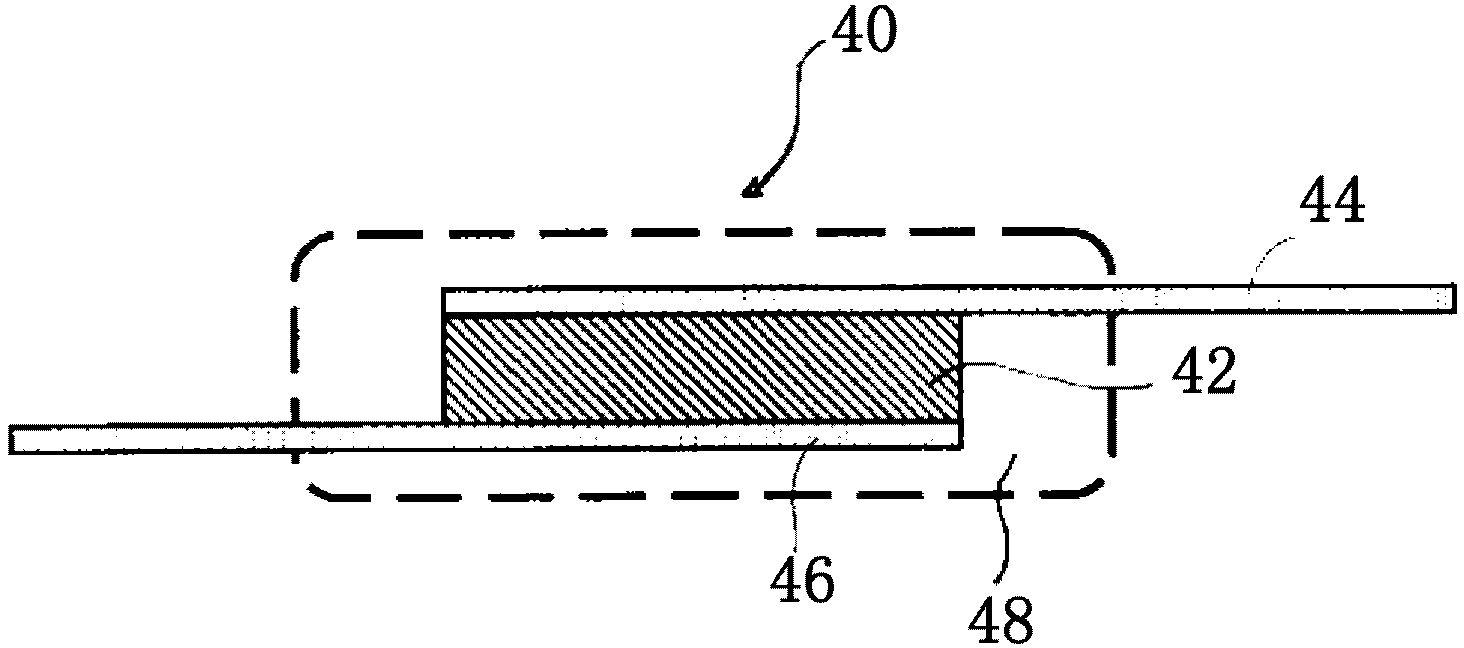

[0073] Using the same PTC parts as in Example 1, insert molding of polypropylene resin produced the image 3 PTC device B of the present invention is shown. The polypropylene resin used was a product name: Prime polypro, manufactured by Prime Polymer Co., Ltd. The conditions of the PTC device B other than the protective member are the same as those of the PTC device A.

[0074] The PTC devices A and B of the present invention thus obtained were immersed in an aqueous KOH solution (1N) at 60° C. for 3 months, and an alkali immersion test was carried out to observe the state of the interface between the protective member and the lead wire to evaluate the effect of alkali generation. influences. Furthermore, a holding current test (I-V test) was performed on the immersed PTC device. In addition, for comparison, the same measurement was performed on other PTC components themselves having the same specifications as the PTC components used in the manufacture of the PTC device. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com