an oxygen tank

An oxygen tank and oxygen technology, applied in the field of medical equipment, can solve the problems of affecting the effect of oxygen inhalation, poor oxygen passage, blockage, etc., and achieve the effect of convenient disassembly and replacement and lightening the economic burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

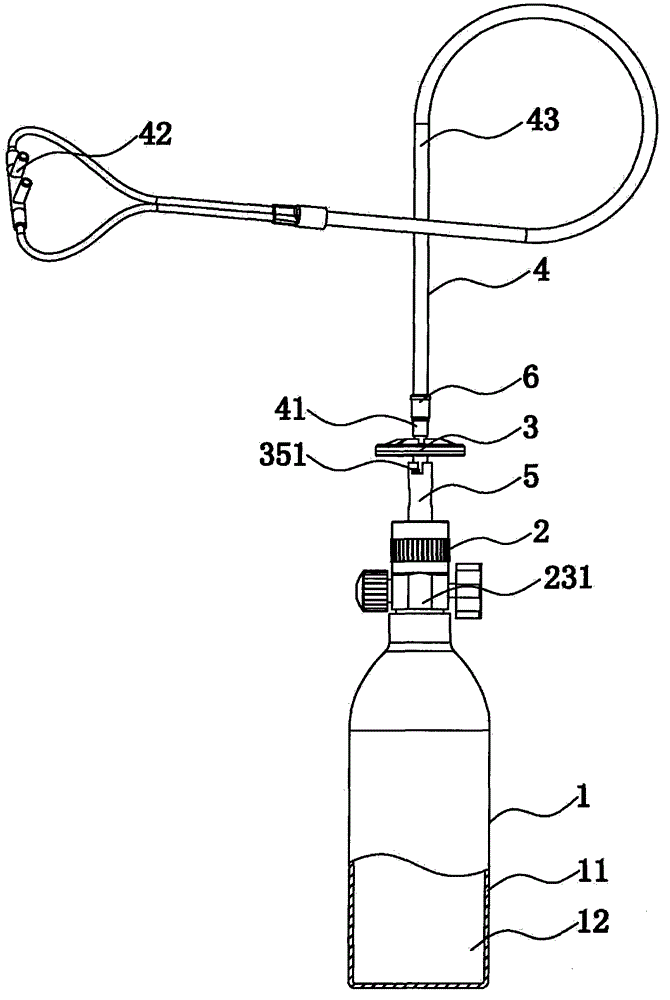

[0029] an oxygen tank such as figure 1As shown, the oxygen tank includes: an oxygen storage container 1, a control component 2, and an oxygen inhalation terminal 4. The oxygen storage container 1 has an internal cavity 12 formed by a container wall 11, and is made of a medical oxygen storage cylinder. After filling The pressure inside the steel cylinder is 12-15 MPa, which stores about 58 liters of oxygen; the upper part of the oxygen storage container 1 is equipped with a control part 2, which is made of lead brass material surface treatment, and the control part 2 can control the oxygen storage container when inhaling oxygen 1. The oxygen stored in the inner cavity 12 is released to the outside. When oxygen is injected, the oxygen can be controlled to enter the inner cavity 12 of the oxygen storage container 1, including the oxygen inlet 21 of the control part, the oxygen outlet 22 of the control part and the oxygen control valve 23, wherein the oxygen The control valve 23 i...

Embodiment 2

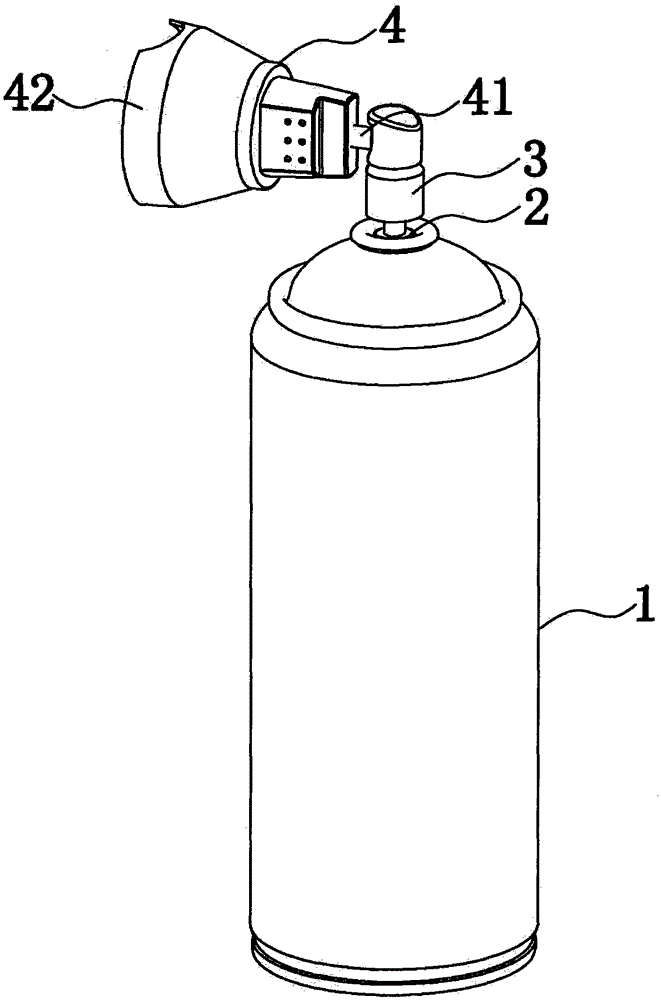

[0038] an oxygen tank such as figure 2 As shown, the oxygen tank includes: an oxygen storage container 1, a control component 2, and an oxygen inhalation terminal 4. The oxygen storage container 1 has an inner cavity 12 formed by a container wall 11, and is made of an aluminum-magnesium alloy. After filling, the pressure in the bottle is 0.8 MPa, and about 4.4 liters of oxygen are stored; the upper part of the oxygen storage container 1 is equipped with a control part 2, which can control the release of the oxygen stored in the inner cavity 12 of the oxygen storage container 1 to the outside, including control Component oxygen inlet 21, control component oxygen outlet 22 and oxygen control valve 23, wherein the oxygen control valve 23 is a gas release valve 232, made of metal material; the oxygen inhalation terminal 4 transmits the humidified oxygen to the human body The parts are composed of an oxygen inhalation mask made of medical plastic injection molding, including an ox...

Embodiment 3

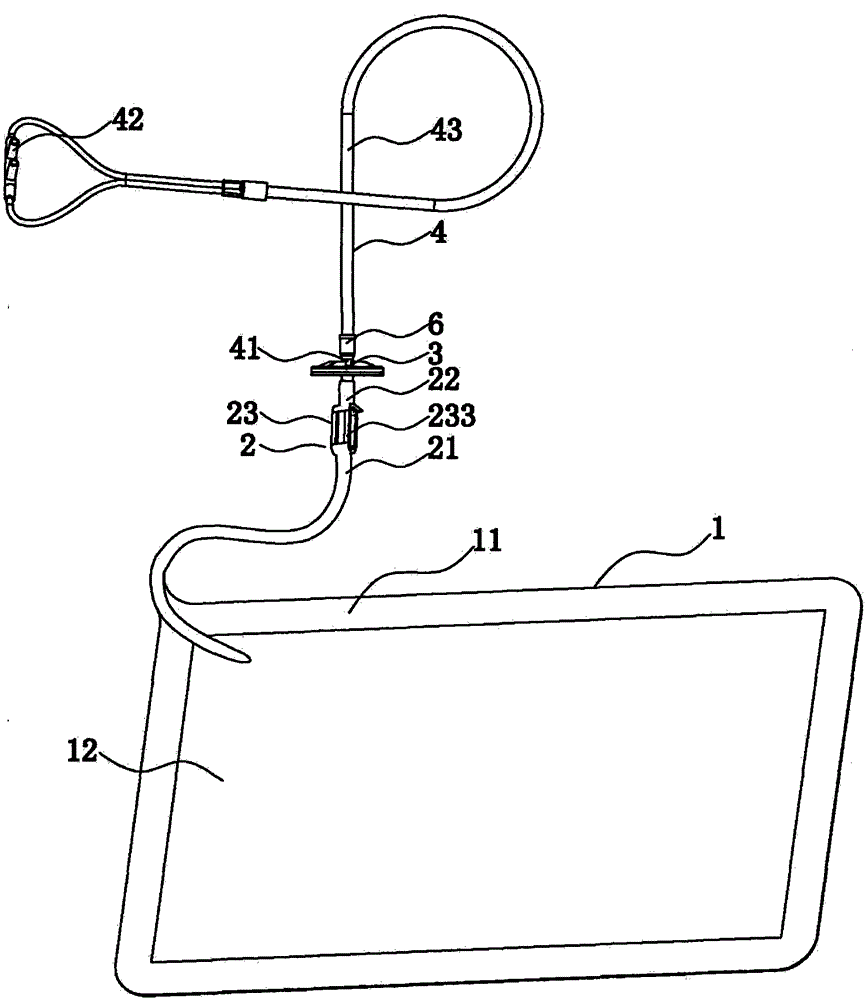

[0042] an oxygen tank such as image 3As shown, the oxygen tank includes: an oxygen storage container 1, a control component 2, and an oxygen inhalation terminal 4. The oxygen storage container 1 is a medical oxygen bag with an inner cavity 12 formed by a container wall 11, which is made of polymer natural rubber and Made of medical professional canvas composite, the pressure in the oxygen bag after filling is less than or equal to 3 kPa; the upper part of the oxygen storage container 1 is equipped with a control part 2, and the control part 2 can control the internal cavity 12 of the oxygen storage container 1 to store oxygen when inhaling oxygen. Oxygen is released to the outside, and oxygen can be controlled to enter the inner cavity 12 of the oxygen storage container 1 when injecting oxygen, including the control part oxygen inlet 21, the control part oxygen outlet 22 and the oxygen control valve 23, wherein the oxygen control valve 23 is a gas switch Valve 233, the oxygen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com