Flushing device and method for second-stage evaporation separator in urea production system

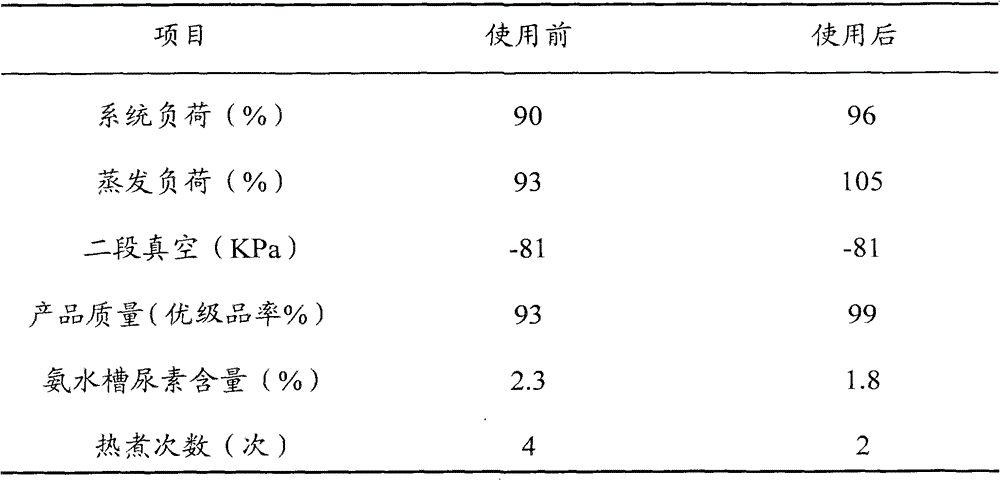

A two-stage evaporation separation and production system technology, applied to the flushing device and field of the two-stage evaporation separator in the urea production system, can solve problems such as hidden dangers in production, achieve the effects of preventing accumulation, improving labor productivity, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to better understand the purpose, structure and function of the present invention, the washing device and method for the second-stage evaporation separator in a urea production system of the present invention will be further described in detail below in conjunction with the accompanying drawings.

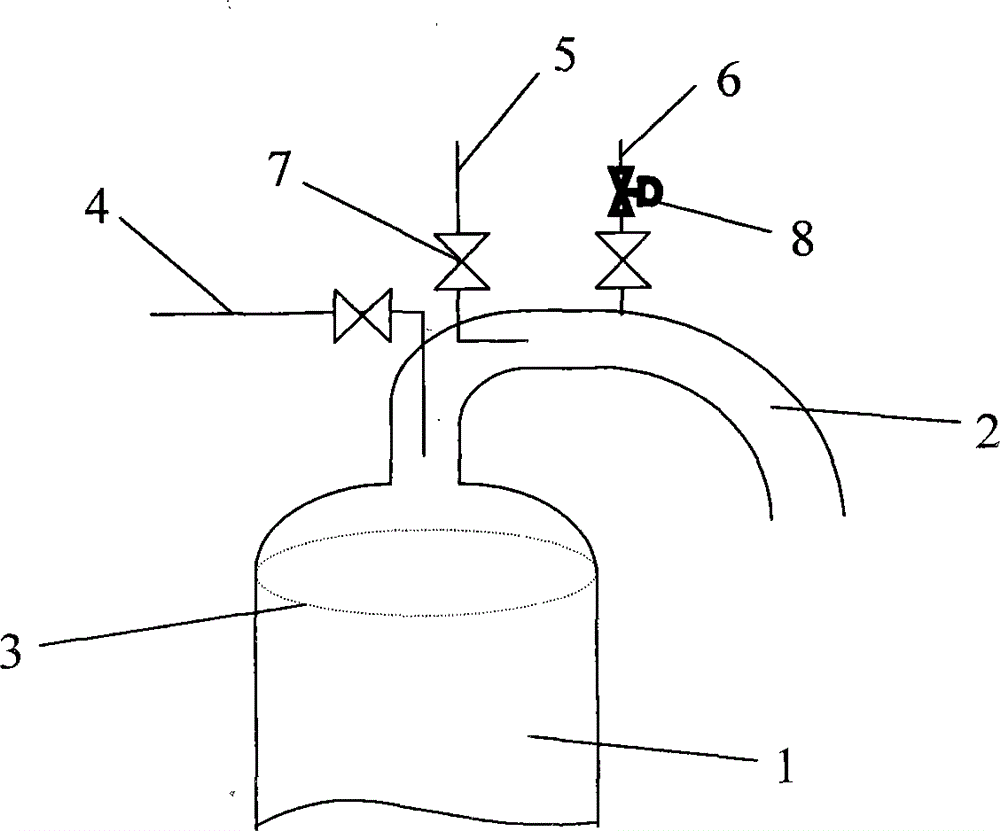

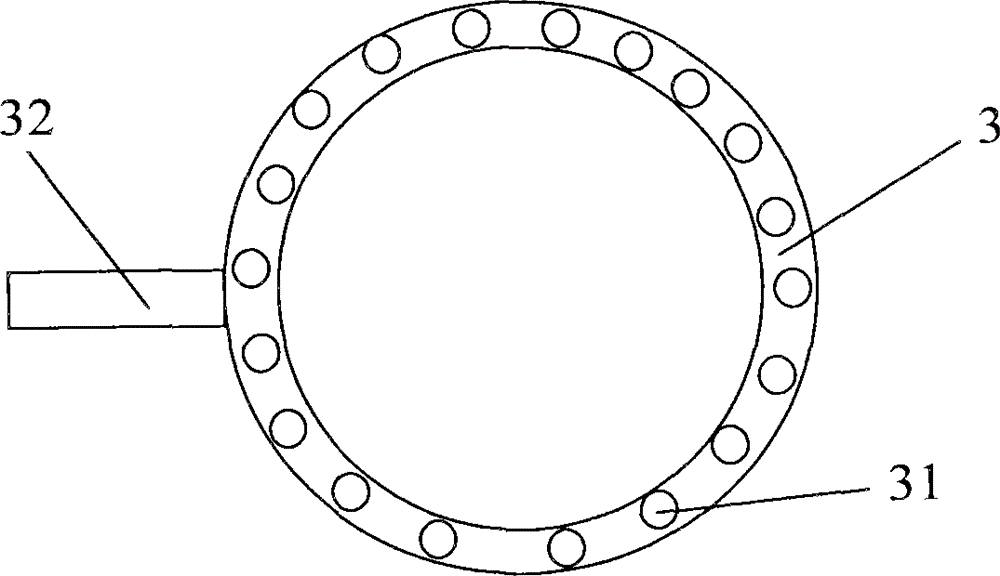

[0014] like figure 1 As shown, the second-stage evaporation separator 1 in the existing urea production system is generally cylindrical, and a gas phase outlet pipe 2 is connected to the top of the separator 1, and the gas phase outlet pipe 2 is usually a U-shaped pipe. The aqueous urea solution is subjected to water vapor separation in the separator 1, so as to obtain a molten urea solution with very little water content.

[0015] However, at present, the steam separated from the separator 1 generally entrains many small urea droplets, which are easy to accumulate at the top of the separator 1 and the gas phase outlet pipe 2, and react to form biuret and other subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com