Diamond section cutting tool

A technology of diamond and cutting tools, which is applied in the field of diamond cutting tools, which can solve the problems of non-replaceable cutting teeth, poor tool life, and poor tool life, and achieve the effects of reduced scrap rate, improved production efficiency, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

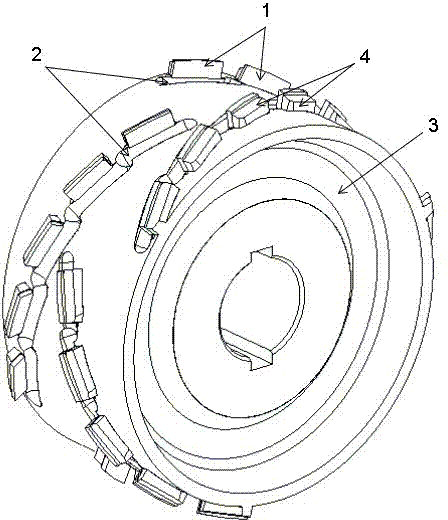

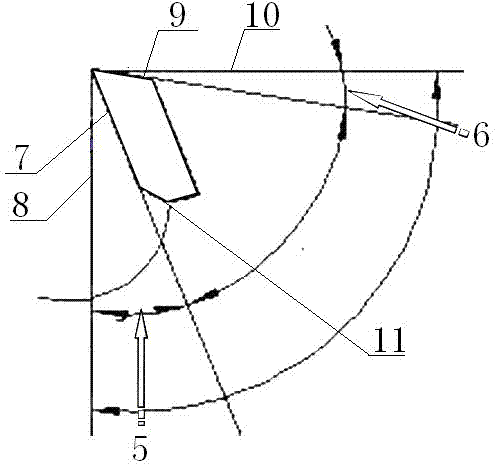

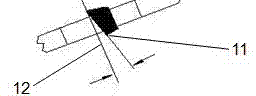

[0014] Such as figure 1 As shown, the cutter includes a cutter body 3, the cutter body 3 is cylindrical, with a step in the middle part, which reduces the weight of the cutter, and the cutter has an inner hole and a keyway. On the circumferential surface of the cutter body 3, there are regularly arranged several groups of continuous chip flutes that are connected in series by a plurality of chip flute monomers 2 to form a "herringbone" shape arrangement. The axis of the continuous chip flutes Angle > 45 degrees. One side of each flute unit 2 is provided with a corresponding tooth seat 4, and the tooth 1 is fixed on the tooth seat 4; the rake angle of the tooth 1 ranges from 5 to 20 degrees, and the rear angle The range is 0 to 20 degrees, and the axial angle ranges from 45 to 80 degrees. And the concentricity of the cutter teeth 1 is 0.02mm. The cutter tooth 1 is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com