Ceramic fiber combined packing block for packing water beam of steel rolling heating furnace and packing method

A technology of ceramic fiber and heating furnace, which is applied in the direction of heat treatment furnace, furnace, furnace type, etc., can solve the problems that the binding block cannot be fixed, the difference between expansion and contraction is large, and it cannot be popularized and applied, so as to achieve heat insulation effect and service life. , small specific heat, good mechanical shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

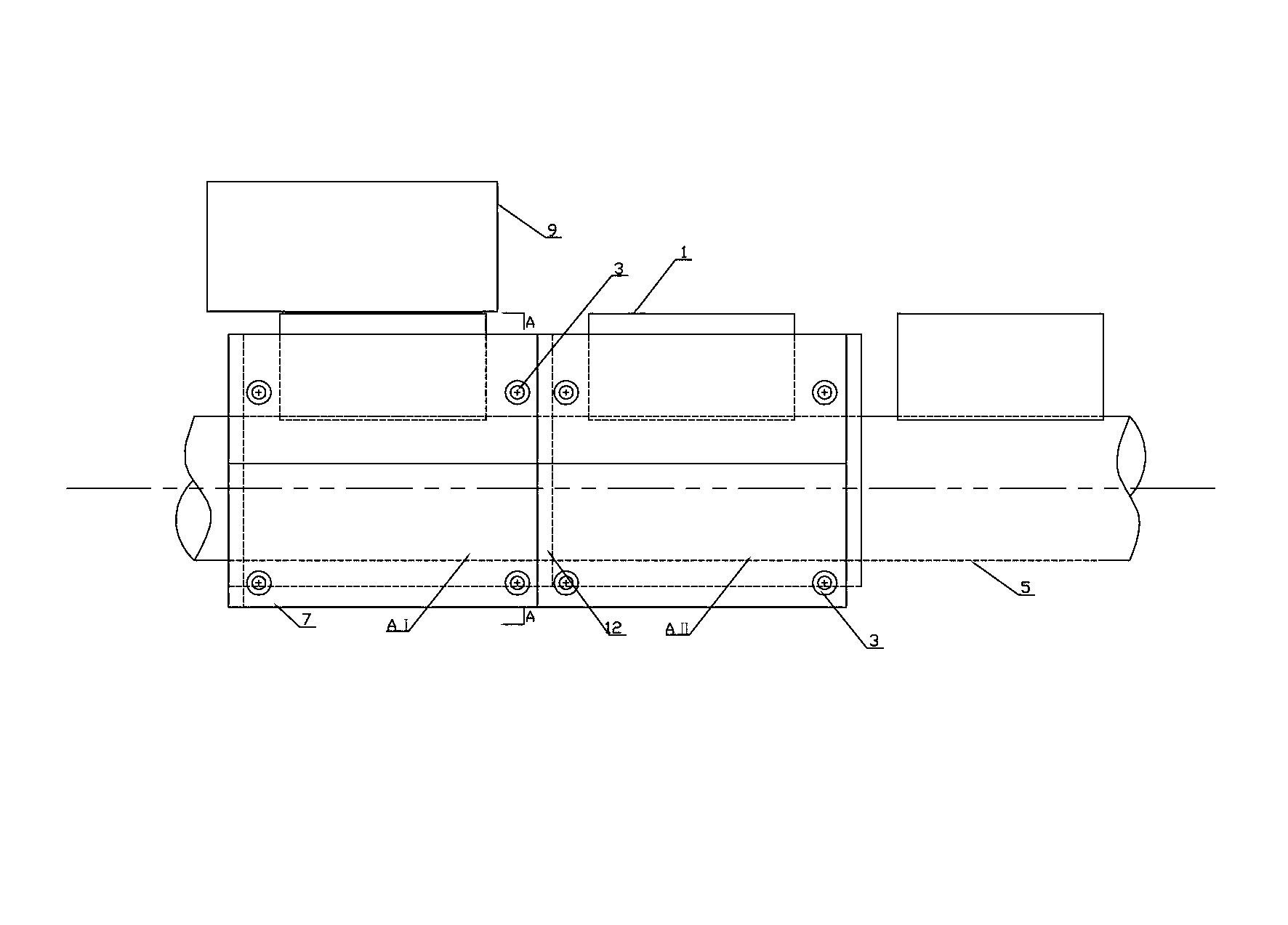

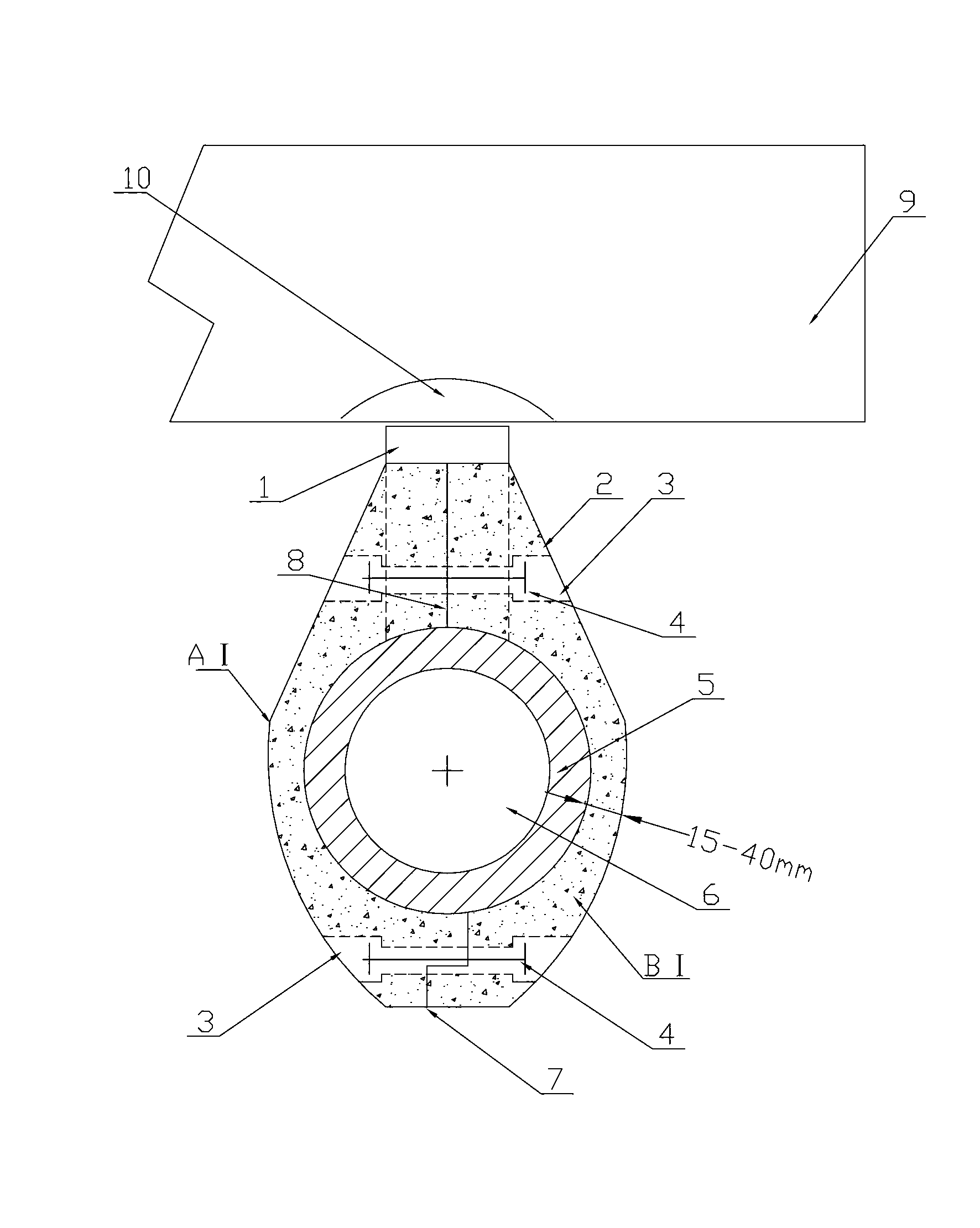

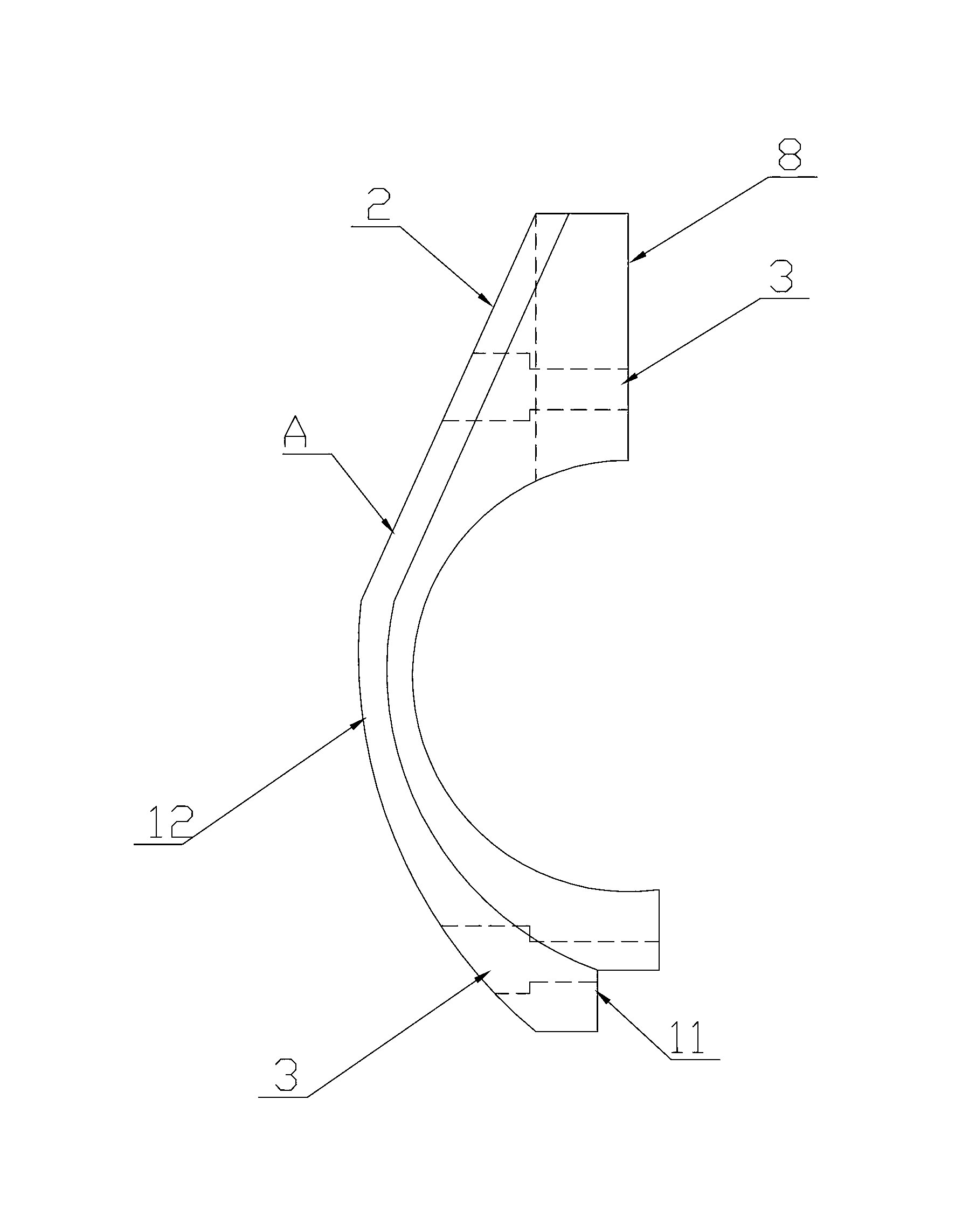

[0040] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0041] like figure 1 - Figure 4 As shown, the ceramic fiber combined binding block for steel rolling heating furnace water beam binding of the present invention includes more than one group of binding blocks surrounding the outer circumference of the heating furnace water beam, and the heating furnace water beam is composed of heating furnace bottom water pipes Composed of slider 1, characterized in that the binding block is made of hard ceramic fiber, the inner side of which is in close contact with the slider and the outer wall of the bottom water pipe of the heating furnace, and two pieces of A and B hard ceramic fiber water pipes are symmetrically occluded and connected. Composed of beam wrapping blocks, there are fastener installation holes 3 on the upper and lower parts of the hard ceramic fiber water beam wrapping blocks A and B, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com