Pile with pile shoulder and pile foundation construction method for pile

A technology of pile shoulders and piles, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of difficult construction, weak bearing capacity, and less soil entry of hammered piles, so as to improve the comprehensive mechanical performance. , Improve the resistance to uplift force and the effect of less material consumption of the pile body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

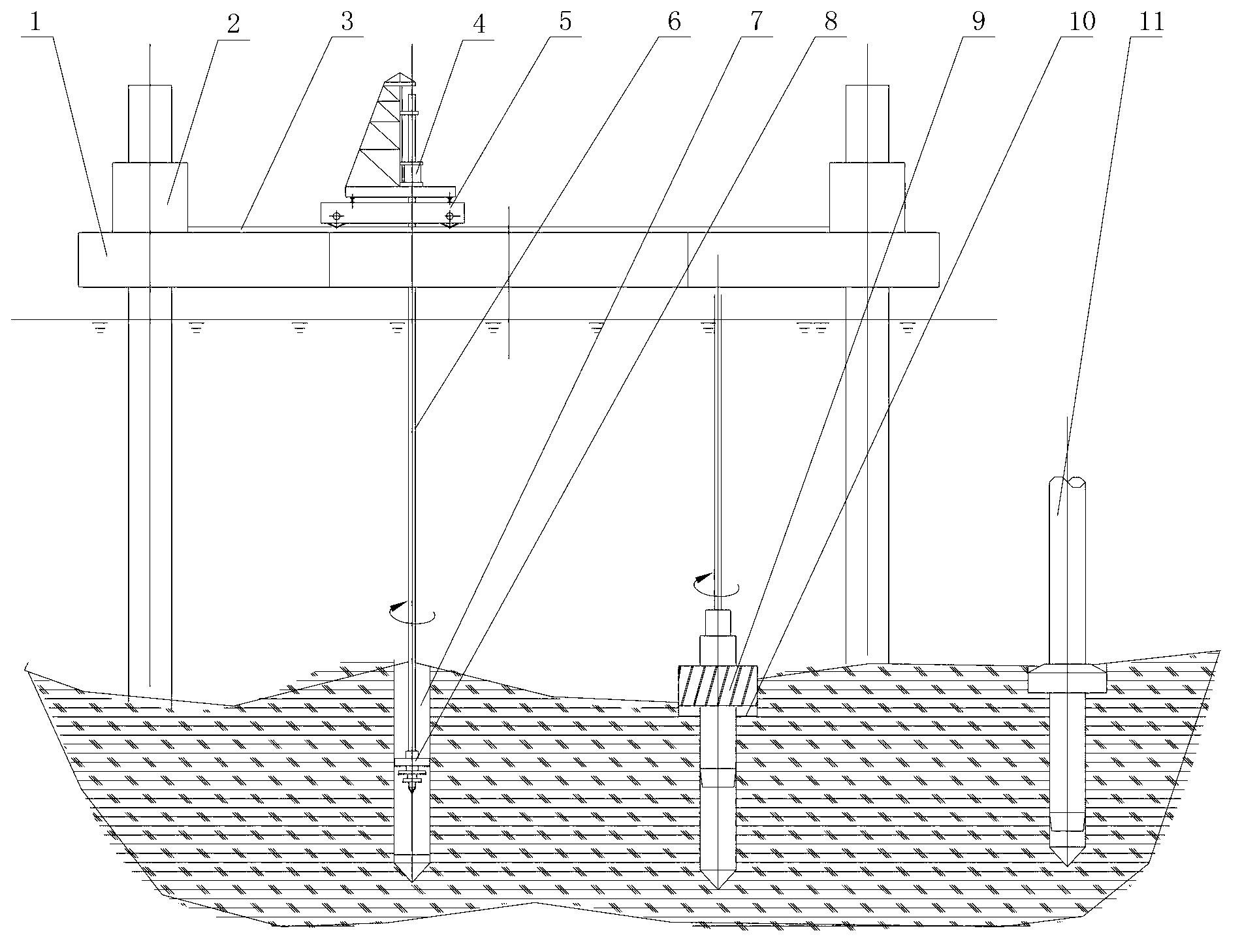

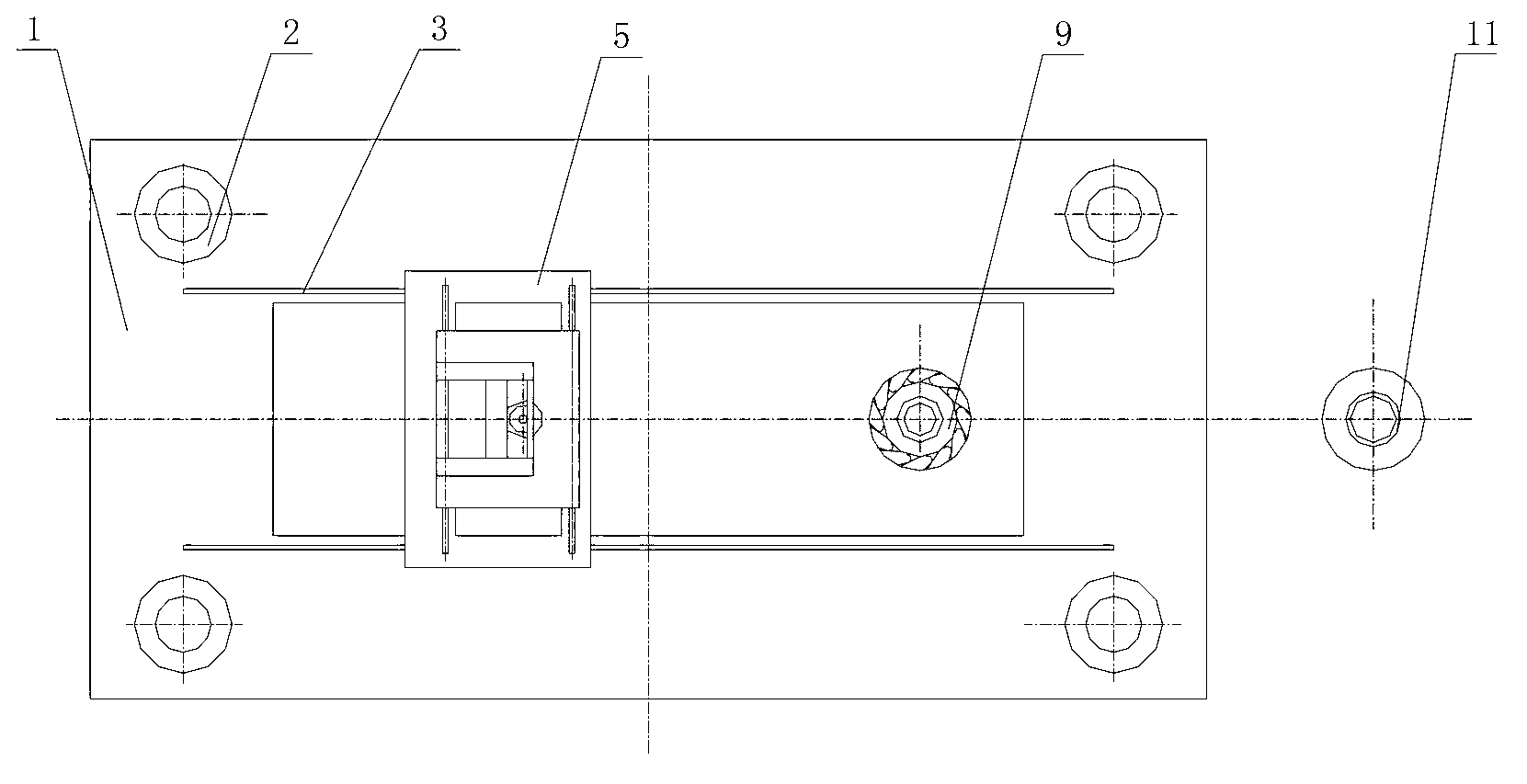

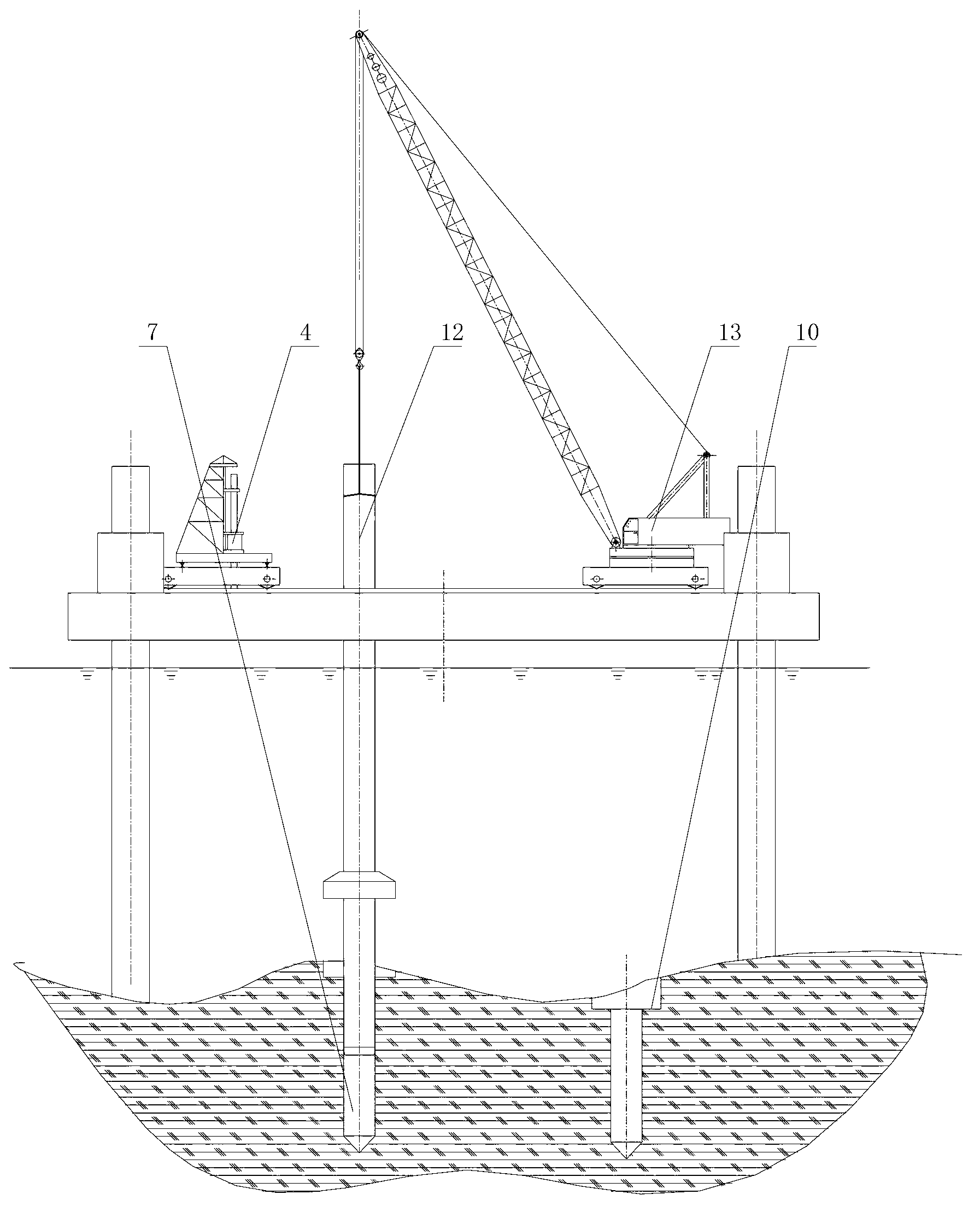

[0041] The piles with pile shoulders are prefabricated first, and the structure of the piles is shown in Figure 4 and Figure 5.

[0042] Such as Figure 4a Shown is an integrally cast reinforced concrete pile with a shoulder having a cylindrical shaft and a disc-shaped shoulder 15 extending outward from the outer surface of the shaft perpendicular to the axis of the shaft, the shoulder being disposed on The lower half of the pile body, the pile body and the pile shoulder are formed by integral casting. Above the upper bottom surface of the pile shoulder is the upper pile body 14, and below the pile shoulder lower bottom surface is the lower pile body 16.

[0043] As a preferred method, the pile shoulder 15 has an upper bottom surface with a smaller diameter, a lower bottom surface with a larger diameter, a circumferential surface extending upward from the outer edge of the lower bottom surface, and an inclined surface connected to the outer edge of the upper bottom surface an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com