Nanometer film pressure sensor based on sacrificial layer technology and manufacturing method thereof

A technology of pressure sensor and sacrificial layer, which is applied to the measurement of the property and force of piezoelectric resistance materials, etc., can solve the problems of good temperature characteristics and low sensitivity ratio, and achieve wide range, low cost, easy integration and miniaturization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

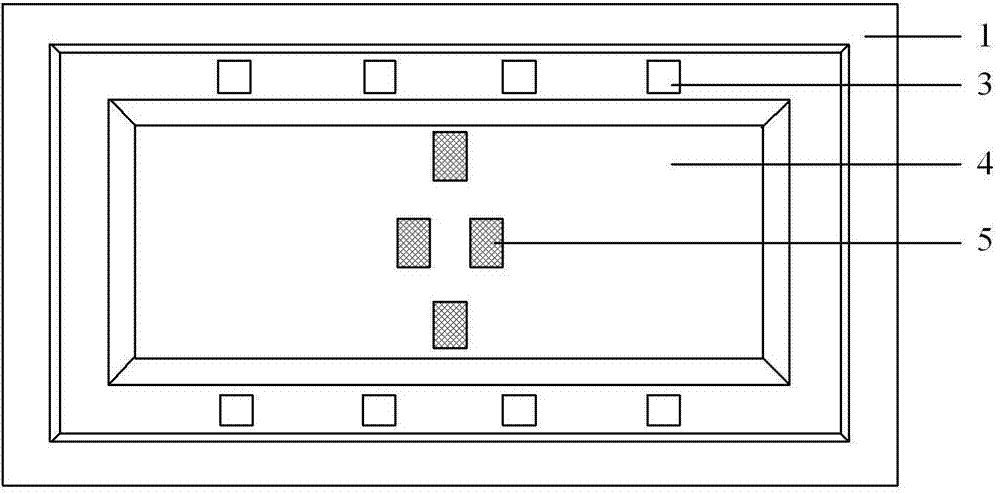

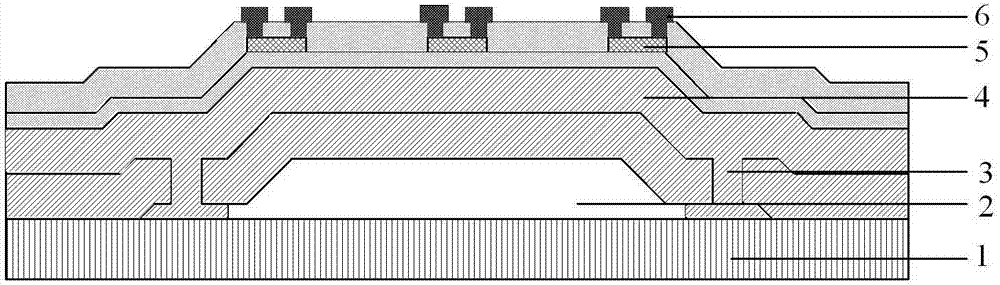

[0061] A nano-membrane pressure sensor based on sacrificial layer technology, the structure is as described above, such as Figure 1~Figure 7 As shown, the process steps of the manufacturing method are as follows:

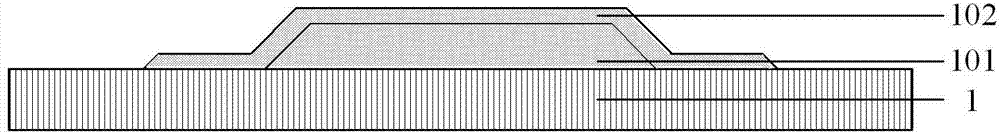

[0062] (1) if image 3 As shown, PECVD is used to deposit silicon dioxide with a thickness of 1.5 μm as the first sacrificial layer 101 (main sacrificial layer), and then deposit a layer of silicon dioxide with a thickness of 0.5 μm to form the second sacrificial layer. 102 serves as an etch channel layer for the sacrificial layer.

[0063] (2) if Figure 4 As shown, LPCVD is used to deposit a layer of polysilicon with a thickness of 2.5 μm to form a polysilicon structure layer, that is, the first layer of polysilicon 103. The annealing conditions are determined according to the conditions of polysilicon deposition (temperature: 900 ° C ~ 1200 ° C; time: 10 min ~ 180 min; nitrogen protection) , forming cavity corrosion holes 3 by dry etching.

[0064] (3) if ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com