Magnetic tile surface defect feature extraction and defect classification method based on machine vision

A feature extraction and defect classification technology, applied in optical testing flaws/defects, instruments, computer parts, etc., can solve the problems of large workload, low efficiency and high missed detection rate for manual visual inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be further described below in conjunction with specific drawings and embodiments.

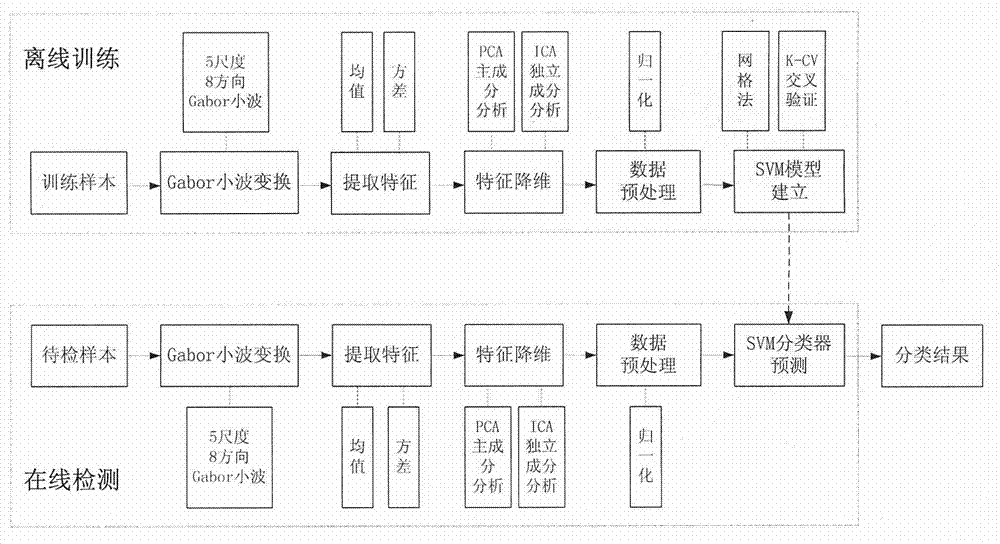

[0080] like figure 1 Shown is the algorithm flow chart of the present invention.

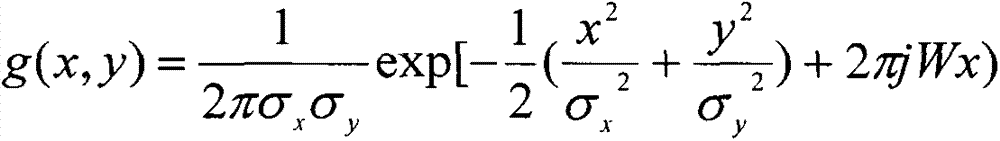

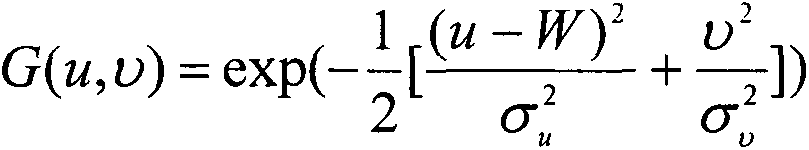

[0081] Step 1: Construct a Gabor filter bank suitable for feature extraction of magnetic tile surface defects, which is a total of 40 Gabor wavelet filter banks in 5 scales and 8 directions, and use the obtained wavelet filter bank to filter the original image.

[0082] Step 2: Extract the mean and variance of 40 filtered images respectively to obtain an 80-dimensional feature vector.

[0083] Step 3: Use PCA (Principal Component Analysis) and ICA (Independent Component Analysis) to reduce the dimension of the feature vector from 80 dimensions to 20 dimensions.

[0084] Step 4: Perform normalized preprocessing on the training sample and the sample data to be tested, and the original data is normalized to [0, 1].

[0085] Step 5: Use the Libsvm toolbox to realize the classifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com