A packaging structure that improves the brightness of vertical light-emitting diode chips

A light-emitting diode and packaging structure technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reduced brightness, low production cost, and poor efficiency of blue light conversion to white light, etc., to achieve the effect of increasing light intensity and enhancing the probability of light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

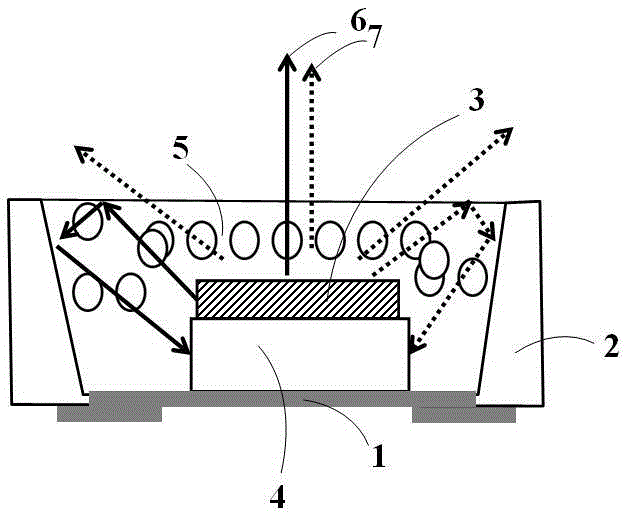

[0028] see figure 2 As shown, a packaging structure for improving the brightness of vertical light-emitting diode chips in this embodiment includes a bracket system, which is mainly used to carry the LED vertical chip 3 on the silicon substrate. The metal support 1 of the structure 8, the function of the metal support 1 is for electrode conduction and heat dissipation, and the function of the surrounding baffle structure 8 is to reduce or prevent the light reflected by the LED vertical chip 3 from being absorbed by the silicon substrate 4, and to absorb it The packaging structure is reflected, in which the height of the surrounding baffle is equal to the substrate thickness of the silicon substrate LED chip; the plastic cup 2 is connected to the periphery of the bracket system, and the shape of the plastic cup can be adjusted according to the need to control the light shape; the silicon substrate LED chip passes through The die-bonding method is placed on the support system; ...

Embodiment 2

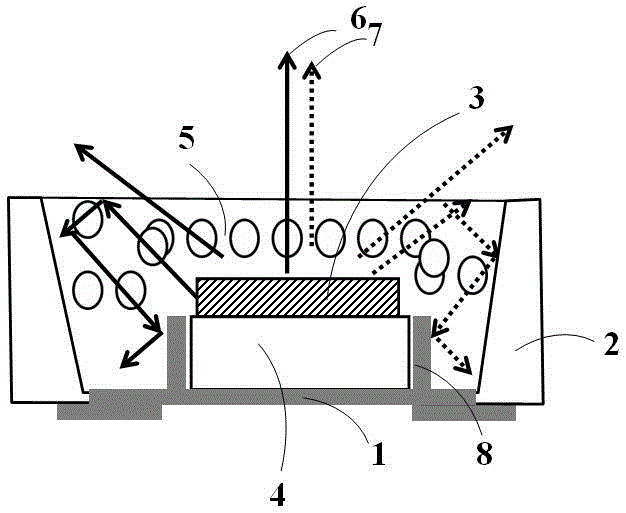

[0032] see image 3 As shown, another packaging structure for improving the brightness of the vertical light-emitting diode chip in this embodiment includes a support system, which is mainly used to carry the silicon substrate LED vertical chip 4, and the support system consists of a metal support 1 and a surrounding type The baffle plate 8 is composed of two separate parts. The metal frame 1 is made of metal materials. The function of the metal frame 1 is for electrode conduction and heat dissipation. The function of the surrounding baffle structure 8 is to reduce or prevent the reflection of the LED chip. The light is absorbed by the silicon substrate and reflected out of the packaging structure, wherein the height of the surrounding baffle is greater than 1 / 2 of the substrate thickness of the silicon substrate LED chip and less than the substrate thickness of the silicon substrate LED chip; the plastic cup 2 and the bracket The periphery of the system is connected, and the ...

Embodiment 3

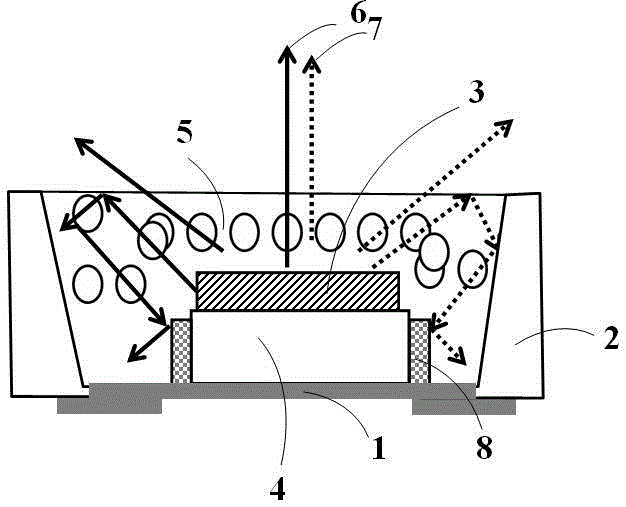

[0036] The difference from Embodiment 1 is that the packaging structure for improving the brightness of the vertical light-emitting diode chip in this embodiment, in which there is a gap between the substrate of the silicon substrate LED chip and the surrounding baffle, is filled with reflective materials, such as White glue (mirror ink), which can further enhance the reflection of blue light and yellow light that would have been absorbed by the silicon substrate, thereby further improving the light intensity of the vertical light-emitting diode chip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com