Stator permanent magnetic flux-switching bearing-free motor with E-shaped teeth

A bearingless motor, magnetic flux switching technology, applied in synchronous machines, electrical components, electromechanical devices, etc., can solve the problems of heat dissipation and mechanical robustness that cannot be ignored, efficiency and power factor are not as good as permanent magnet motors, and permanent magnet utilization rate is reduced. and other problems, to achieve high reliability, ability to operate with faults, compact structure, and high power density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

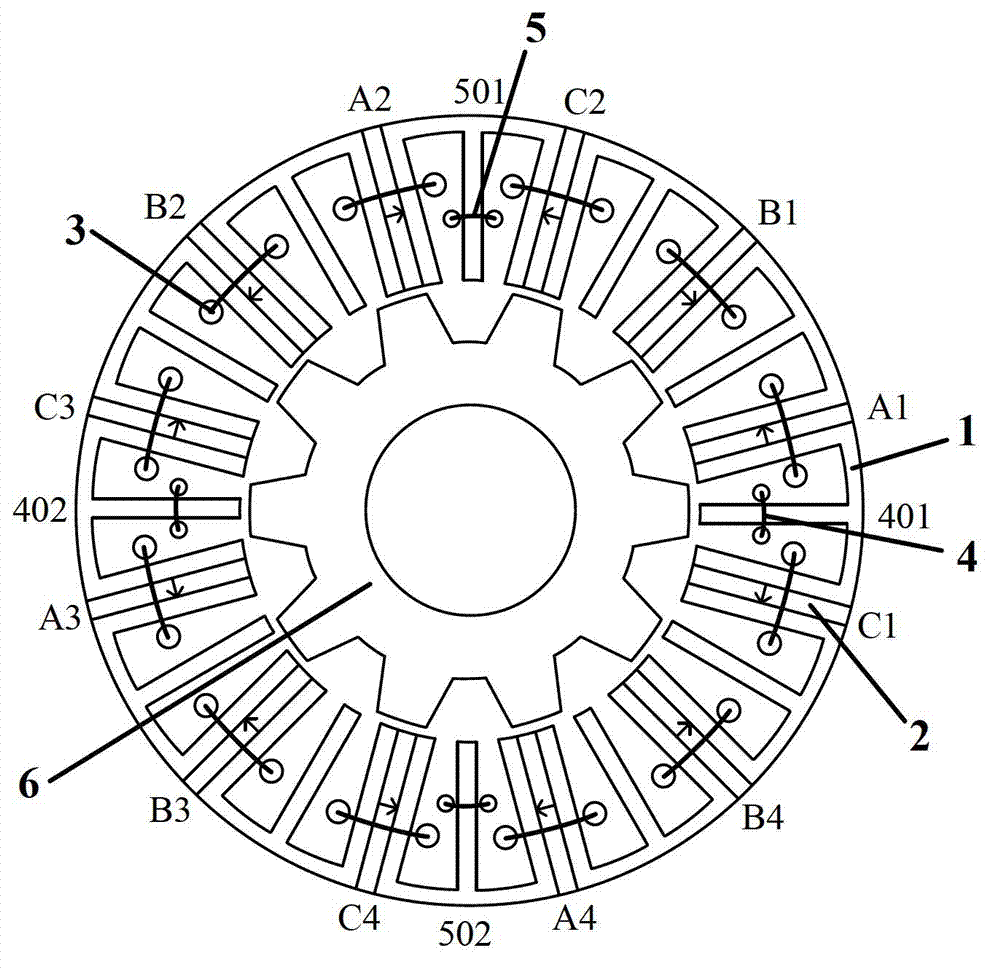

[0032] see figure 1 , the stator permanent magnet flux switching bearingless motor of the present invention includes a stator 1 and a rotor 6, the rotor 6 is located inside or outside the stator 1, both the stator 1 and the rotor 6 are salient pole structures, and the stator 1 is provided with a three-phase symmetrical centralized Type armature winding 3, X-axis suspension winding 4, Y-axis suspension winding 5 and permanent magnet 2.

[0033] Taking a three-phase stator 12-pole / rotor 10-pole stator permanent magnet flux switching bearingless motor as an example, its cross-sectional view is as follows figure 1 As shown, there are 12 uniformly distributed armature tooth core units and 12 uniformly distributed fault-tolerant teeth on the stator, the armature tooth core units and fault-tolerant teeth are distributed alternately, and there are 10 uniformly distributed salient poles on the rotor; the stator core consists of Composed of 12 "E" type magnetic core units, a tangential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com