A kind of antistatic impregnated product and preparation method thereof

An antistatic and antistatic agent technology, applied in the field of polyvinyl chloride molded products and preparation, to achieve the effects of reducing viscosity, reducing resistivity, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

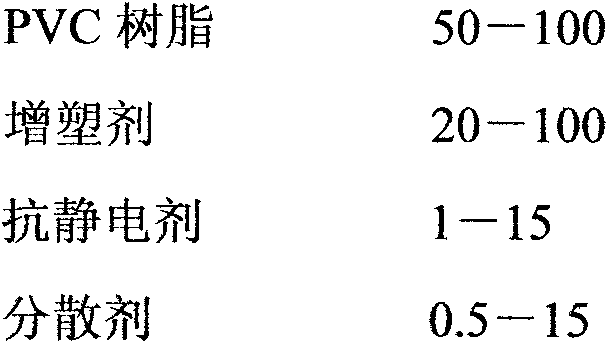

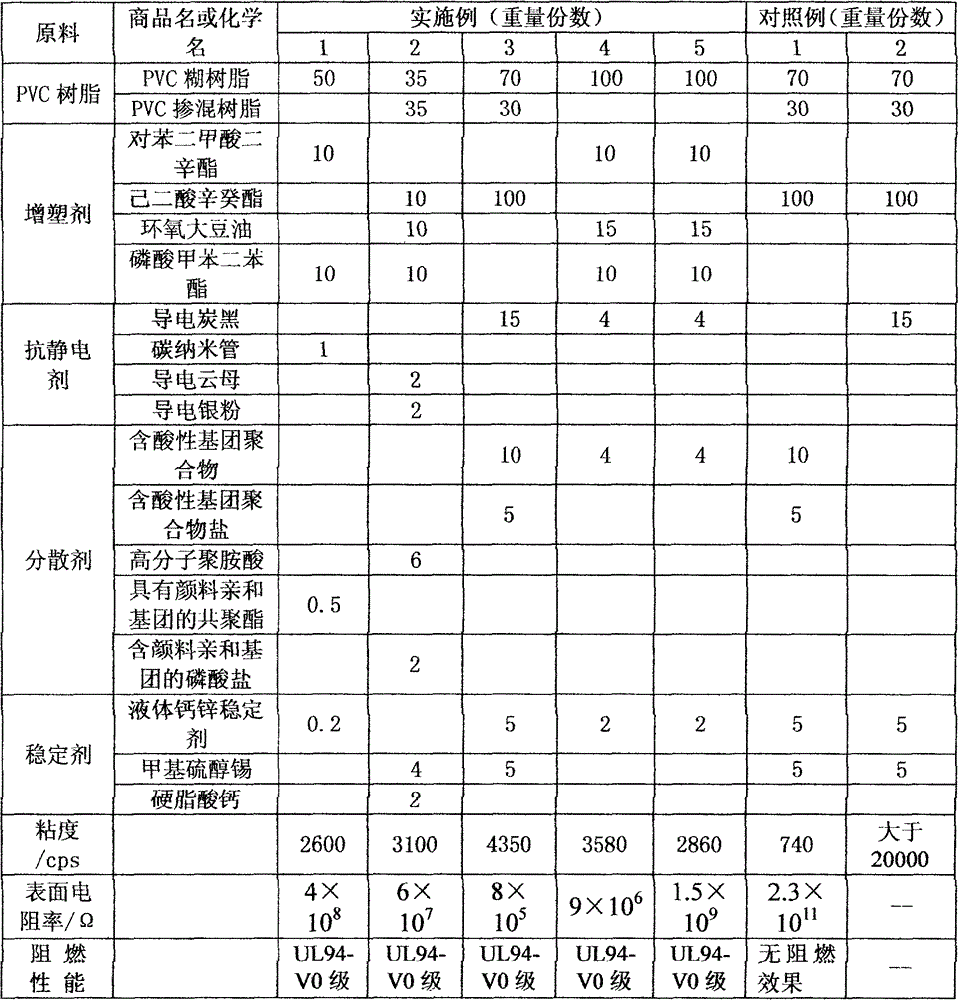

[0023] This example relates to a dip-molded product with flame-retardant and antistatic properties, including the components and parts by weight shown in Table 1.

[0024] 1. Mix the above-mentioned raw materials (except the antistatic agent), then add the antistatic agent, and mix evenly to obtain a flame-retardant and antistatic plastic dipping solution, with a viscosity of 2600cps at 25°C; the carbon nanotubes are nanomaterials ;

[0025] 2. First heat the mold with the desired shape to 120°C, then immerse the mold in the dipping solution, and take it out after 120 seconds;

[0026] 3. Put the mold covered with plastic layer into an oven at 200°C, and plasticize for 80 seconds;

[0027] 4. Take the plasticized and molded product out of the oven to cool for 5 seconds, and demould to obtain a flame-retardant and antistatic dip-molded product.

[0028] The surface resistivity of the obtained impregnated product is 4×10 8 Ω2, vertical burning up to UL94-V0 standard.

Embodiment 2

[0030] This example relates to a dip-molded product with flame-retardant and antistatic properties, including the components and parts by weight shown in Table 1.

[0031] 1. Mix the above-mentioned raw materials (except the antistatic agent), then add the antistatic agent, and mix evenly to obtain a flame-retardant and antistatic plastic dipping solution. The viscosity is 3100cps at 25°C; the conductive mica is a micron material, Conductive silver powder is a nano material;

[0032] 2. First heat the mold with the desired shape to 190°C, then immerse the mold in the dipping solution, and take it out after 80 seconds;

[0033] 3. Put the mold covered with plastic layer into an oven at 300°C, and plasticize for 10 seconds;

[0034] 4. Take the plasticized and molded product out of the oven to cool for 20 seconds, and demould to obtain a flame-retardant and antistatic dip-molded product.

[0035] The surface resistivity of the obtained impregnated product is 6×10 7 Ω, vertica...

Embodiment 3

[0037] This example relates to a dip-molded product with flame-retardant and antistatic properties, including the components and parts by weight shown in Table 1.

[0038] 1. Mix the above raw materials (except the antistatic agent), then add the antistatic agent, and mix evenly to obtain a flame-retardant and antistatic plastic dipping solution. The viscosity is 4350cps at 25°C; the conductive carbon black is nanometer and Micron according to 1:1 mixed material;

[0039] 2. First heat the mold with the desired shape to 250°C, then immerse the mold in the dipping solution, and take it out after 1 second;

[0040] 3. Put the mold covered with plastic layer into an oven at 550°C, and plasticize for 2 seconds;

[0041] 4. Take the plasticized and molded product out of the oven to cool for 45 seconds, and demould to obtain a flame-retardant and antistatic dip-molded product.

[0042] The surface resistivity of the obtained impregnated product is 8×10 5 Ω, vertical burning up to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com