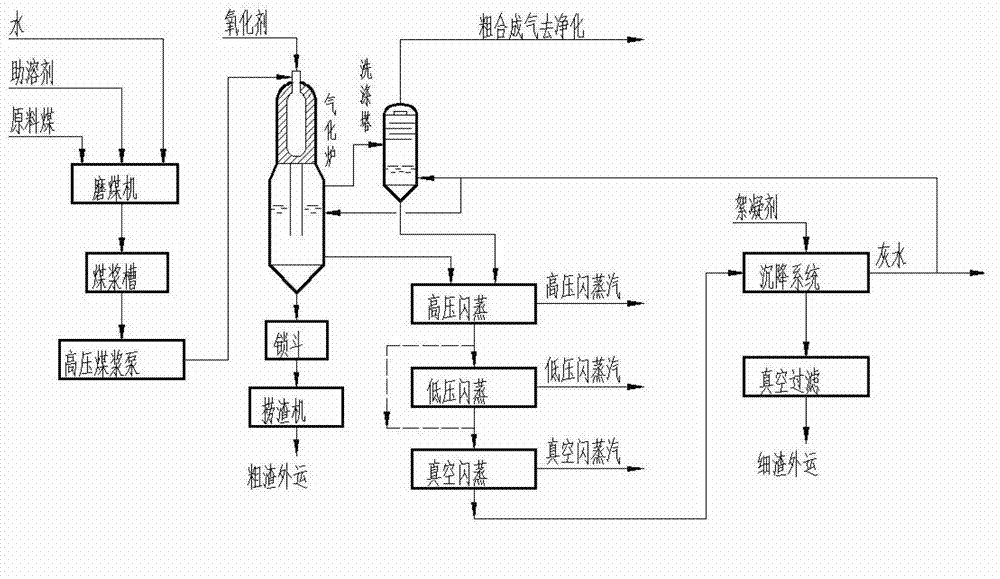

Coal gasification ash content treatment device and method

A treatment method and treatment device technology, which is applied in the direction of manufacturing combustible gas, petroleum industry, joint combustion mitigation, etc., can solve the problems of easy scaling and blockage of pipelines and equipment, high procurement and construction costs, and ash content in the medium, etc., to achieve land occupation Small size, low construction cost, and the effect of a small number of pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

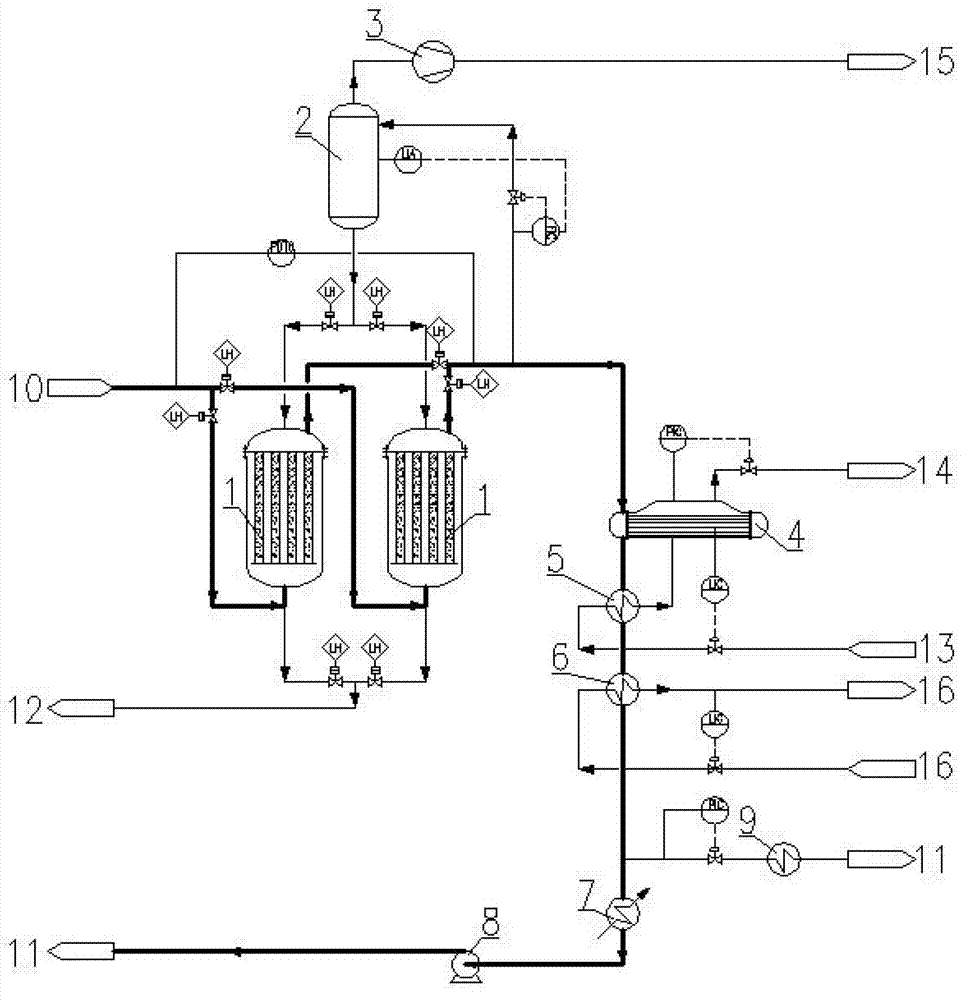

[0032] The main equipment adopted by the coal gasification ash processing method adopted in the present invention comprises:

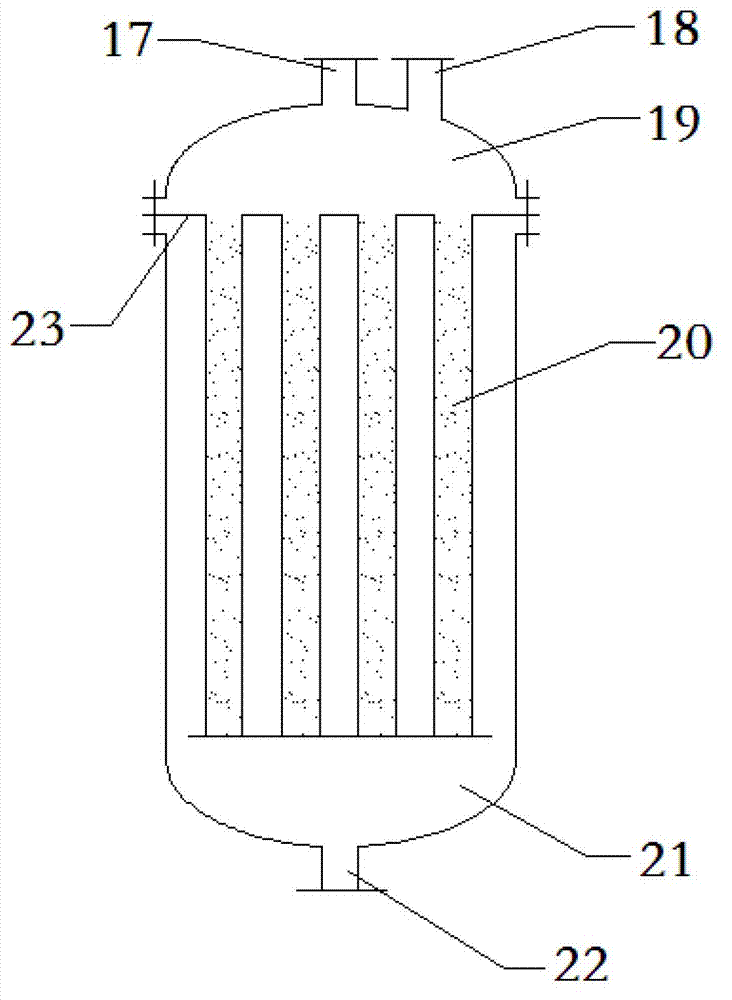

[0033] a. High-pressure ash remover; two sets are connected in parallel and serve as backups for each other, and conventional sintered metal filter tubes are used in the ash remover;

[0034] b. Waste heat boiler;

[0035] c. Boiler water heater;

[0036] d. Fresh water heater;

[0037] e. Backwash flash tank; the backwash flash tank is equipped with backwash water inlet, outlet and exhaust port, and the backwash flash tank backwash water outlet is connected to the backwash water inlet of the ash remover;

[0038] f. A first gray water cooler and a second gray water cooler;

[0039] g. Gray water pump;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com