A machining process and a rework process for a mask plate for vapor deposition

A processing technology and mask technology, which is applied in vacuum evaporation coating, metal material coating technology, sputtering coating and other directions, can solve the problems of large upper and lower openings and small middle openings, so as to improve the film forming rate and reduce scrap. The effect of improving the accuracy of opening size and production pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The main innovation of the present invention is that the present invention innovatively proposes a processing technology of a mask plate for evaporation, please refer to Figure 8 , processing technology of the present invention comprises the steps:

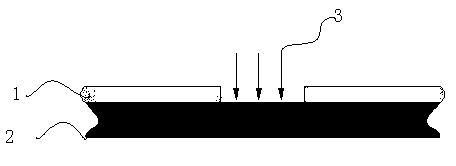

[0052] Step S1: See figure 1 , image 3 , the etching starts, part of the surface of the metal mask 2 is protected by patterns (exposure dry film) 1, 3, and the rest of the surface of the metal mask 2 is in contact with the etching solution. At this time, the etching proceeds vertically to the depth (direction of arrow 4).

[0053] In this embodiment, the material of the mask can be Invar alloy; the thickness of the mask is 30-150 μm.

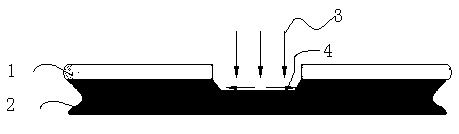

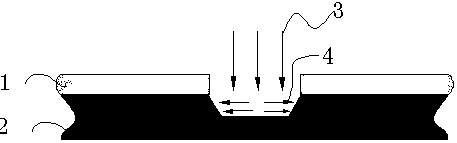

[0054] Step S2: See figure 2 , when the upper surface of the metal mask 2 is etched to a certain depth, a new metal mask surface appears on both sides of the bare, at this time, the etchant flows to both sides (arrow 4) in addition to the vertical direction (arrow 4) 5 direction) for ...

Embodiment 2

[0071] The invention proposes a repairing process of a mask plate for vapor deposition, which adopts sandblasting micro-processing to repair the mask plate with unqualified openings. see Figure 6 , Figure 7 , carry out sand blasting treatment to the protrusion 10 at the opening, the sand blasting treatment is as Figure 6 In the direction indicated by the middle arrow 8, a new opening 9 is formed; the difference between the upper and lower dimensions of the opening and the middle dimension meets the setting requirements.

[0072] After the sandblasting micro-treatment, conduct a secondary inspection on the opening of the mask to judge whether it is qualified; if the difference between the upper and lower dimensions of the opening and the middle dimension is still greater than the set value, continue to perform sandblasting without treatment until the deviation of the opening size is controlled within ±20μm .

[0073] In one embodiment of the present invention, the micro-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com