Construction method for adopting concrete breast board piles to support side slope with height difference of foundation pit

A construction method and earth retaining board technology, applied to sheet pile walls, foundation structure engineering, excavation, etc., can solve problems such as inability to ensure safety, surrounding foundation subsidence, superstructure damage, etc., to shorten the support time and save the construction site Small, prevents water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

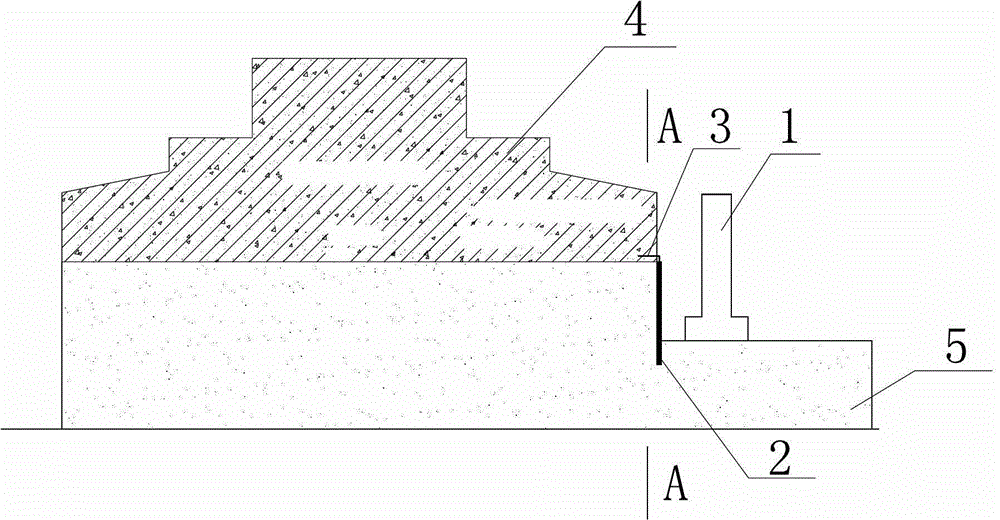

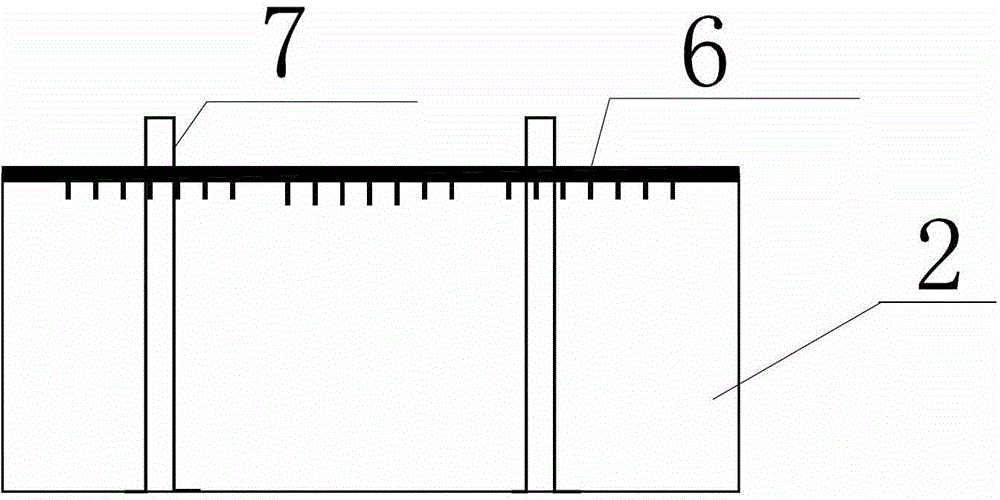

[0023] In the embodiment of the construction method in which the height difference slope of the foundation pit is supported by concrete retaining sheet piles 2, the shallow foundation pit is the foundation 4 of the blast furnace body, and the bottom elevation is -4.2m, and the deep foundation pit is the pipe trench of the casting yard Foundation 5, bottom elevation -7.5m. Such as Figure 1-Figure 3 As shown, the construction method includes the following steps:

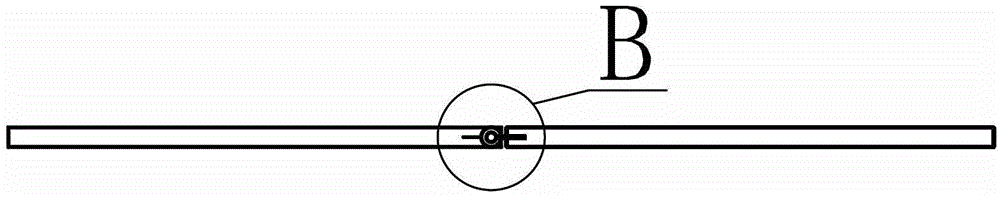

[0024] S1, fabricate concrete retaining sheet piles 2, and pre-embed anchor bars 3 at the top of the retaining sheet piles 2 at a certain distance. One side of retaining sheet pile 2 is provided with mother groove 9, and mother groove 9 is the steel pipe that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com