Range hood and stove all-in-one machine

An all-in-one machine and range hood technology, which is applied to household stoves, oil fume removal, water heaters/stoves, etc., can solve the problems of low efficiency of oil fume removal and high comprehensive energy consumption of range hoods, and achieve volume reduction and indoor temperature and humidity. The effect of reducing the fluctuation and reducing the exhaust air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

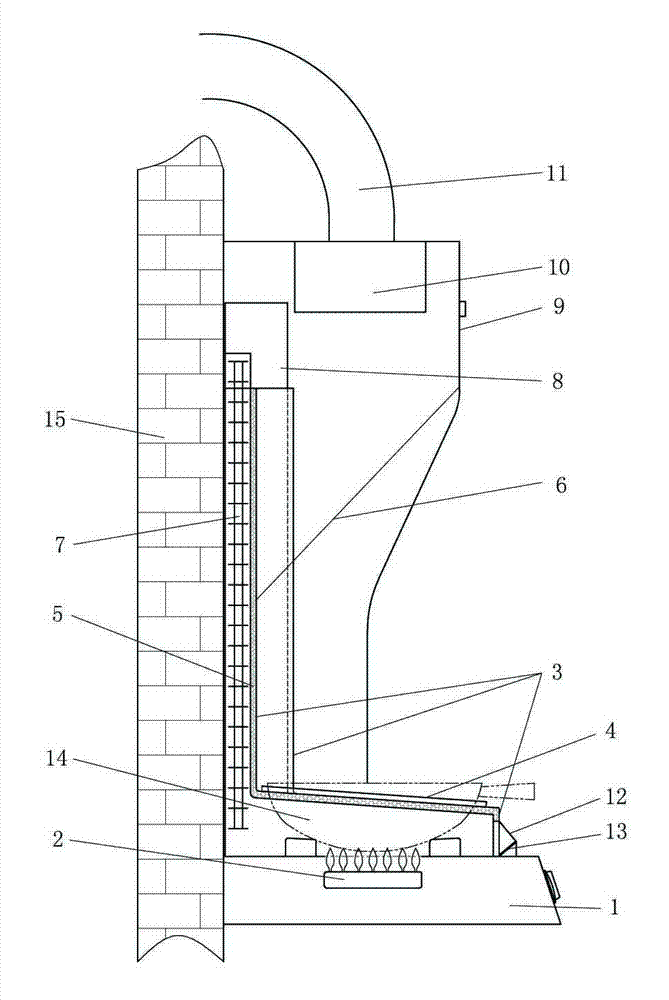

[0016] refer to figure 1 , the smoke stove integrated machine includes: stove, stove burner and combustion chamber, shunt cover, furnace ring, heat insulation layer, range hood, range hood fume filter and exhaust fan, heat exchanger and exhaust gas channel, water tank , exhaust pipe, flame observation window, reflector. The pot and walls are also illustrated for ease of understanding.

[0017] The cooker hood of the smoke cooker integrated machine of the present invention adopts a small thickness design, so that the height of the range hood is reduced, and the cooker fume can be captured at a short distance. When cooking, the variable-diameter ring located above the burner of the stove and installed on the diverter hood is opened. When the pot is placed on the burner, the ring shrinks and hugs the circumference of the pot wall to form a closed combustion chamber under the pot; if a collar is used The furnace ring, the pot goes down into the combustion chamber through the hol...

Embodiment 2

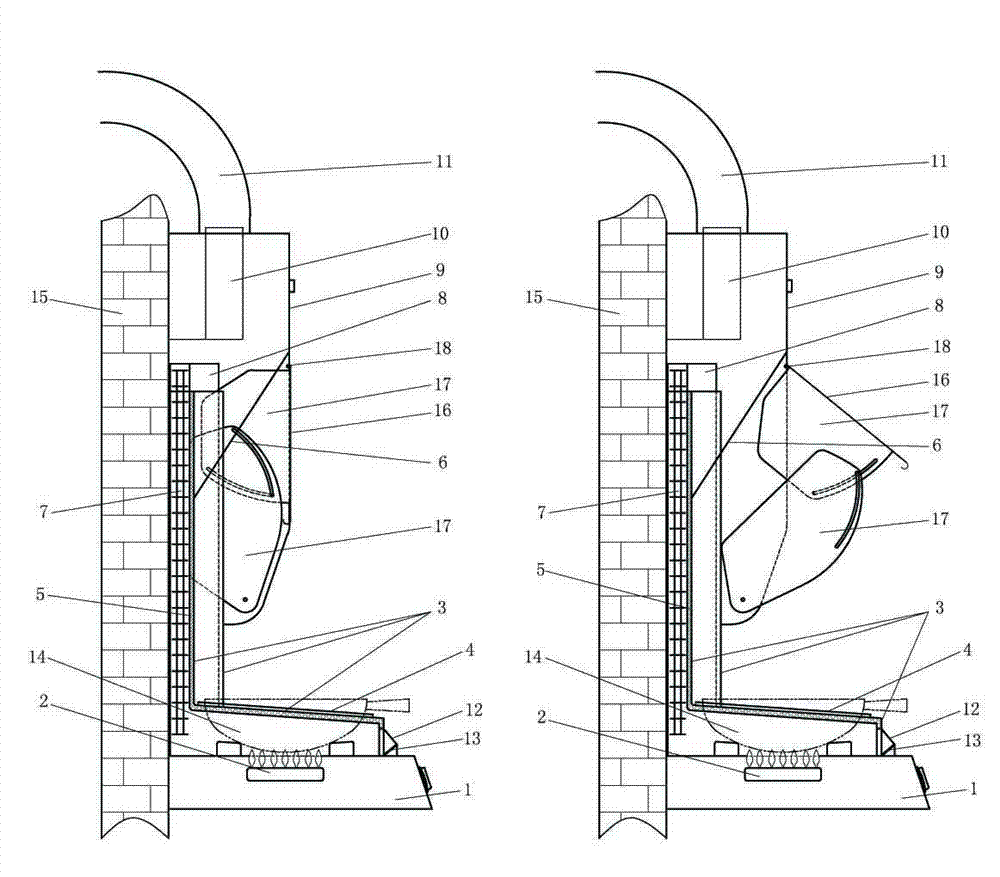

[0019] refer to figure 2 , the basic structure of this embodiment is similar to that of Embodiment 1, the difference is that a movable fume collecting hood that can rotate around the rotation axis and a side of the fume collecting hood that moves with the fume collecting hood are added to the front face of the range hood. plate. The left side of the picture shows the fume collecting hood in the stowed position, and the right side shows the fume collecting hood in the unfolded position. When not cooking, the fume collecting hood is put away to reduce the kitchen space occupied by the fume stove integrated machine; when cooking, rotate the fume collecting hood to hover at an appropriate position, and maximize the range hood’s protection against oil fume without affecting the operation. coverage area. The fume collecting hood, the side panels of the fume collecting hood, and the oil fume filter form an inverted funnel, and the lower opening of the inverted funnel is closer to ...

Embodiment 3

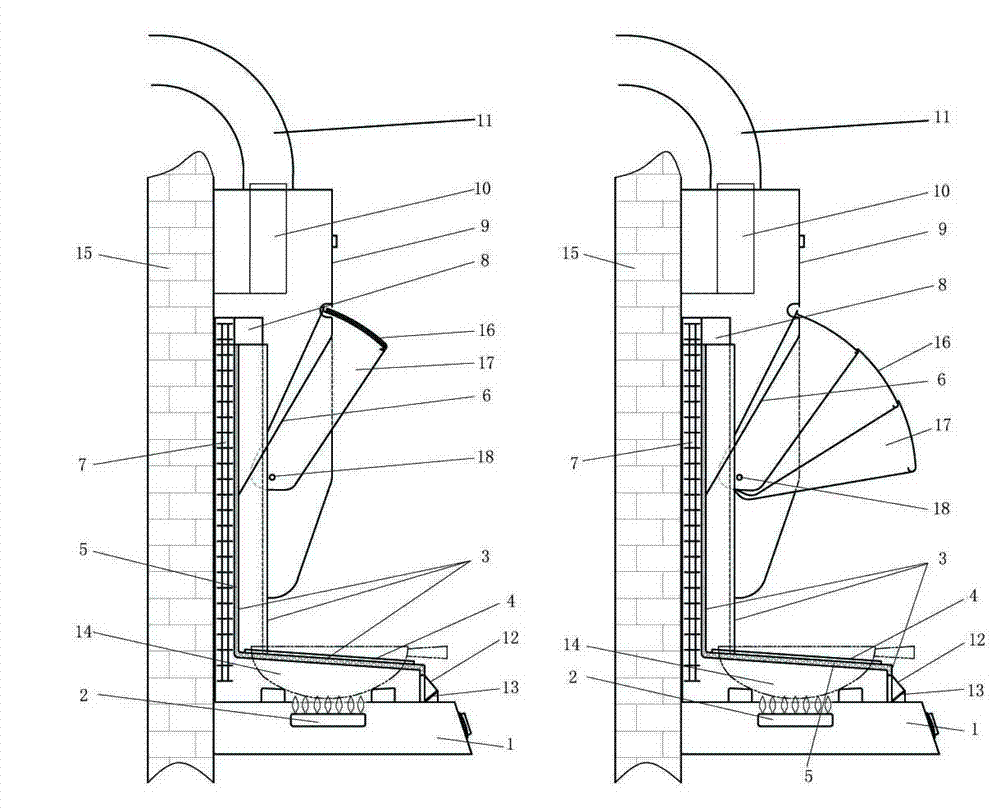

[0021] refer to image 3 , The structure of embodiment 3 is basically the same as that of embodiment 2, the difference is that the fume collecting hood of embodiment 3 is composed of several arc surfaces, and the rotation axis is located at the lower part of the fume collecting hood. The left side of the picture shows the fume collecting hood retracted, and the right side shows the fume collecting hood unfolded. When cooking, the fume collecting hood is rotated and unfolded to an appropriate position, so as to increase the coverage area of the range hood to the fume. With this structure, in addition to ensuring better oil fume capture, a larger cooking operation space can also be provided.

[0022] Variable diameter furnace ring:

[0023] Figure 4 It is the variable-diameter furnace ring structure of the shunt hood, and its basic components include a fixed ring, a swing blade, and a blade shaft. The fixed ring is installed on the shunt cover, and its center is aligned w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com