Dynamic performance testing system for fuel cell automobile power system

A fuel cell and power system technology, used in vehicle testing, engine testing, machine/structural component testing, etc., can solve the problems of few influencing factors, no comprehensive consideration, low integration, etc. Powerful, highly integrated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

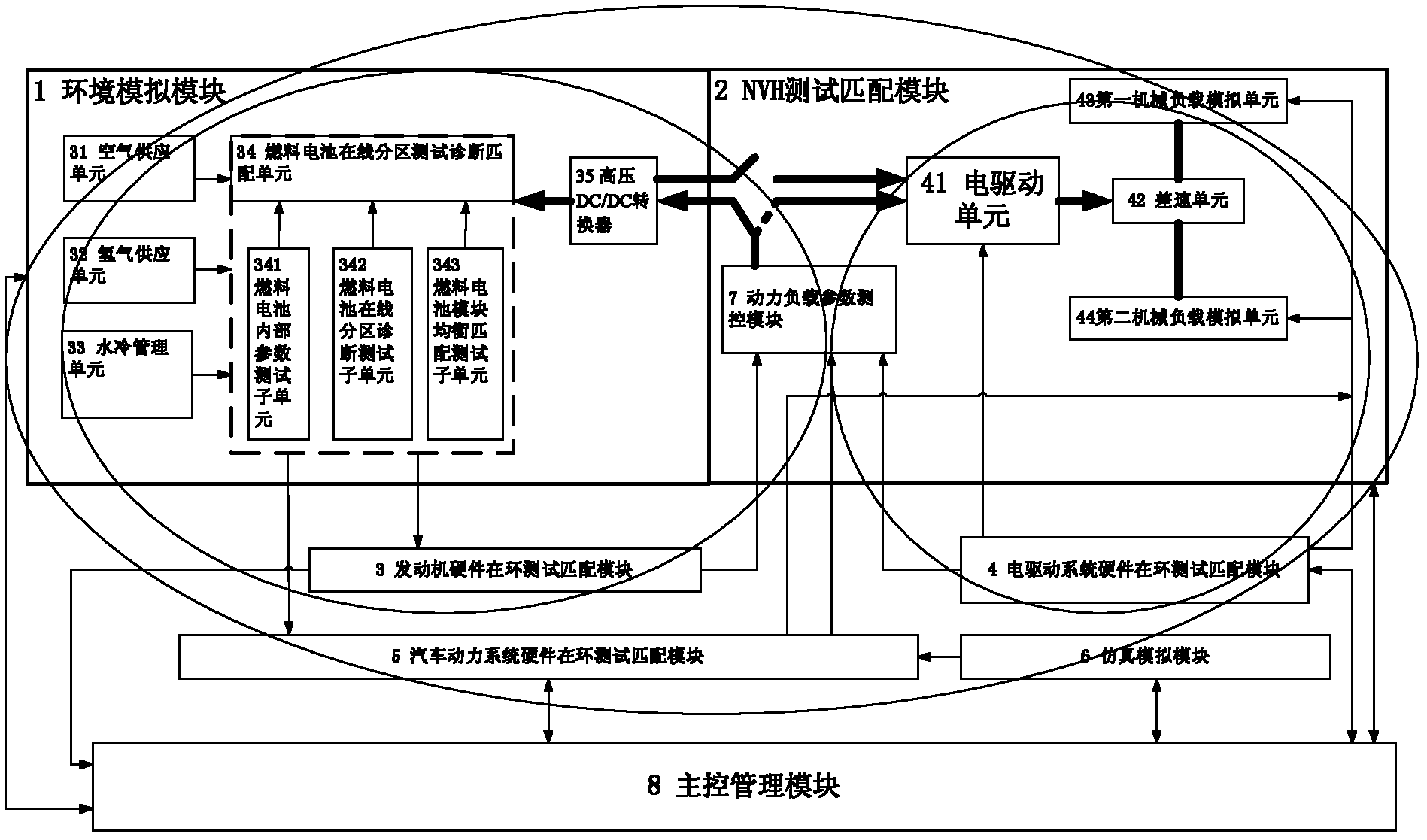

[0053] Such as figure 1 As shown, a dynamic performance test system for fuel cell vehicle power system includes the following modules:

[0054] Environmental simulation module 1: used to provide the temperature, humidity and pressure environment under the actual working conditions of the fuel cell vehicle engine;

[0055] NVH test matching module 2: used to provide the NVH environment of the fuel cell vehicle electric drive system under actual working conditions;

[0056] Engine hardware-in-the-loop test matching module 3: replace the electric drive system with an electronic load, and perform an in-loop matching test on the engine hardware in the environmental simulation module;

[0057] Electric drive system hardware-in-the-loop test matching module 4: Based on the analog power supply configuration, conduct an in-loop matching test on the electric drive system hardware in the NVH test matching module;

[0058] Vehicle power system hardware-in-the-loop test matching module 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com