Filtering reactance level and variable frequency driving system using same

A technology of variable frequency drive and filter reactance, which is applied in the field of filter reactance and can solve problems such as limited effect of common mode current suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

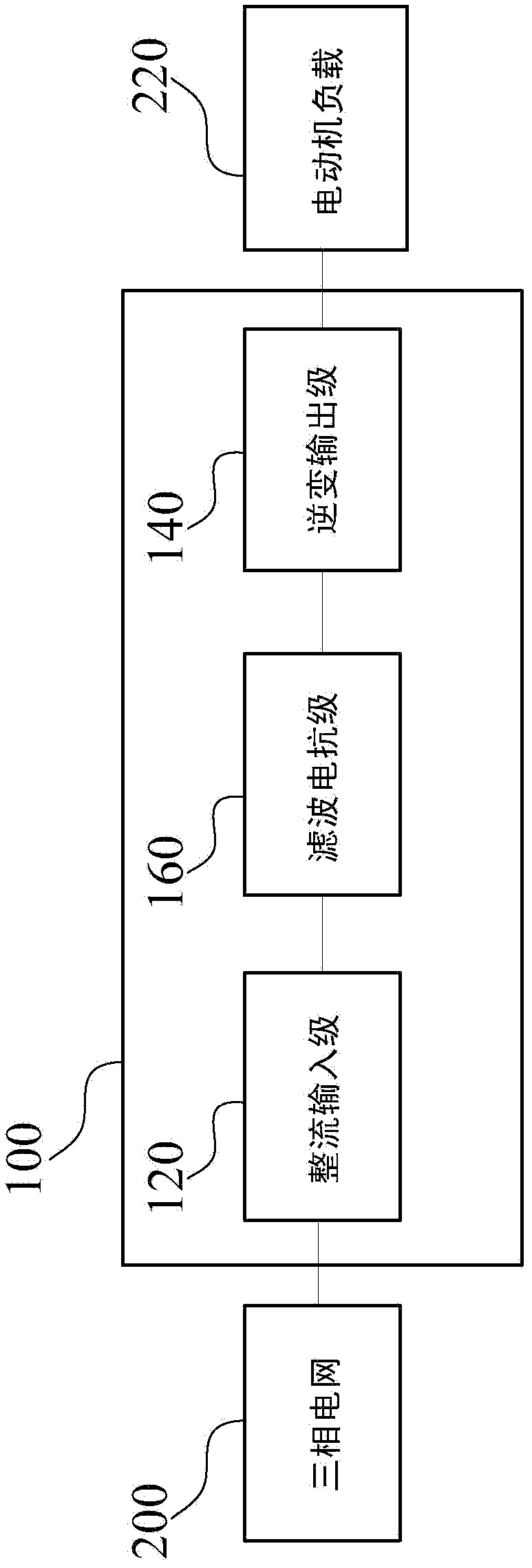

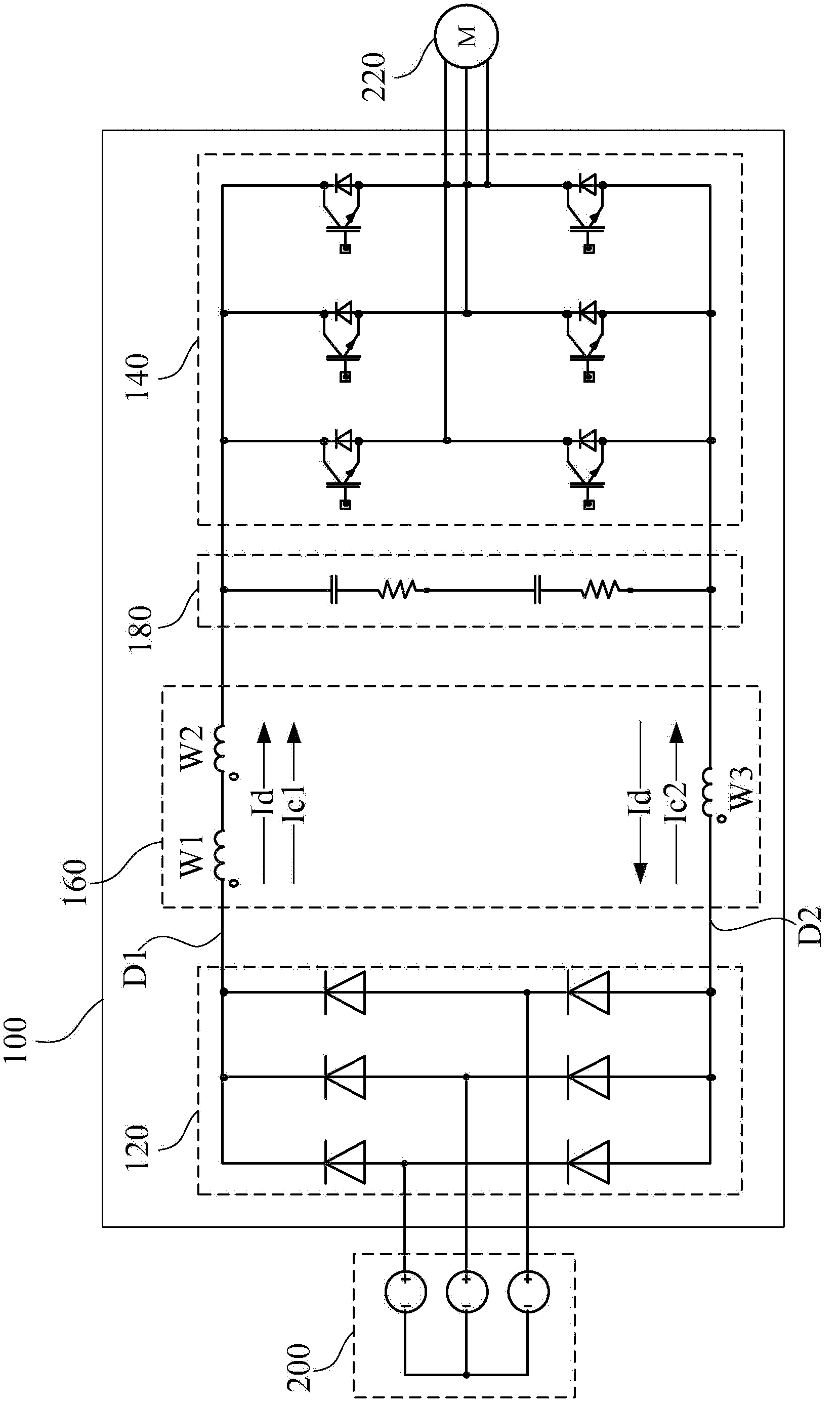

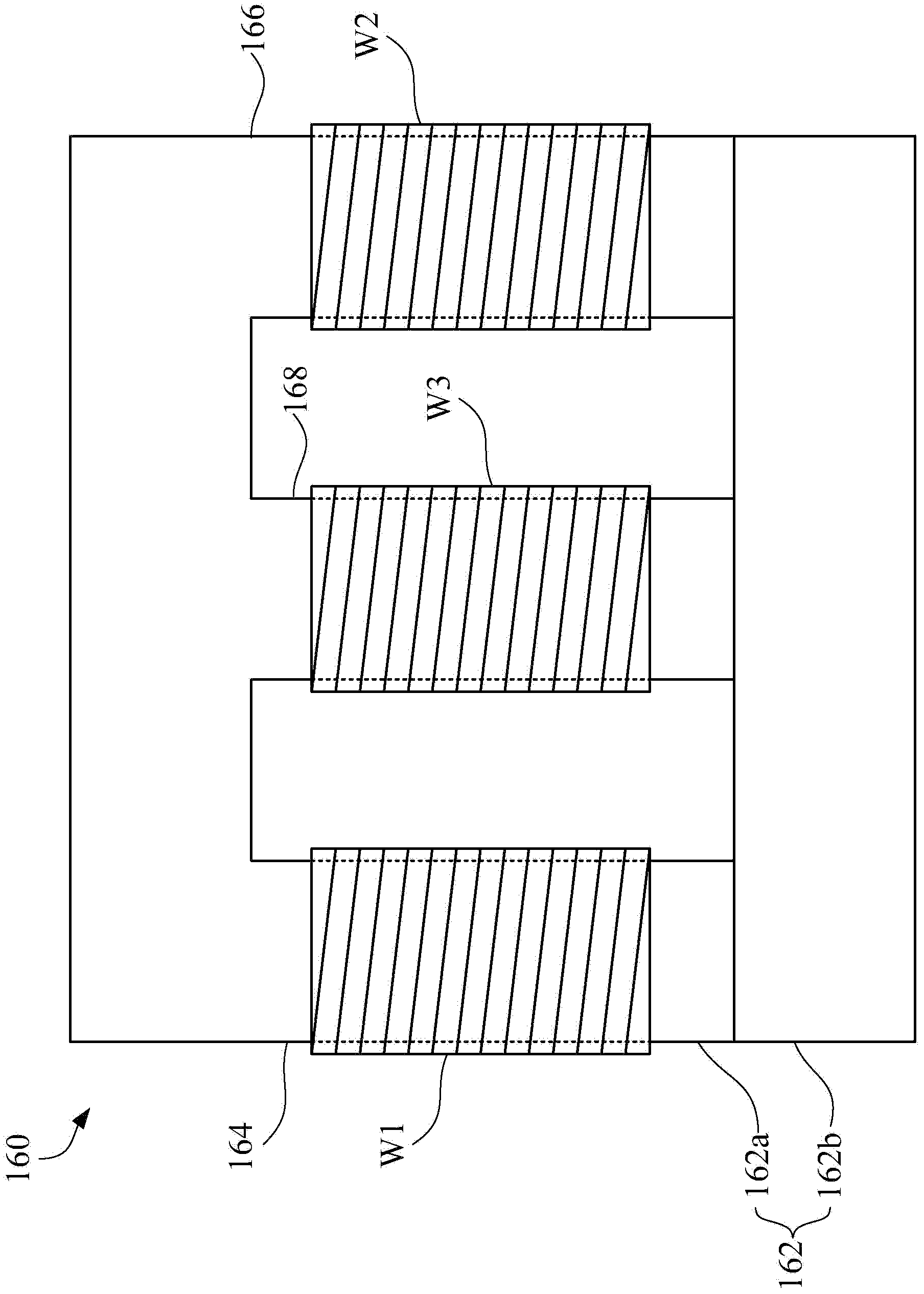

[0046] see figure 1 , which is a functional block diagram of a variable-frequency drive (Variable-frequency Drive, VFD) system 100 in a preferred embodiment of the present invention. Such as figure 1 As shown, the variable frequency drive system 100 includes a rectifier input stage 120 , an inverter output stage 140 and a filter reactance stage 160 .

[0047] In this preferred embodiment, the variable frequency drive system 100 can receive an AC input voltage with a fixed operating frequency from the three-phase grid 200, adjust the frequency and amplitude of the AC input voltage, and then use the adjusted AC output voltage to drive an external motor load 220 (such as an induction motor), in this way, the rotational speed of the motor load 220 can be smoothly controlled.

[0048] As mentioned above, the rectifier input stage 120 is electrically connected to the three-phase grid 200 . The rectifying input stage 120 is used to convert the AC input voltage with a fixed operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com