Production method of manual flat and single-bud type green tea

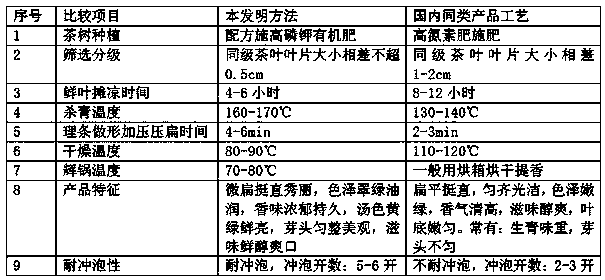

A production method and single bud technology are applied to the production field of manual flat single bud green tea, which can solve the problems of unsustainable aroma of single bud green tea, easy deterioration of color, uneven bud head, etc. The effect of reducing the killing time and even the buds and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

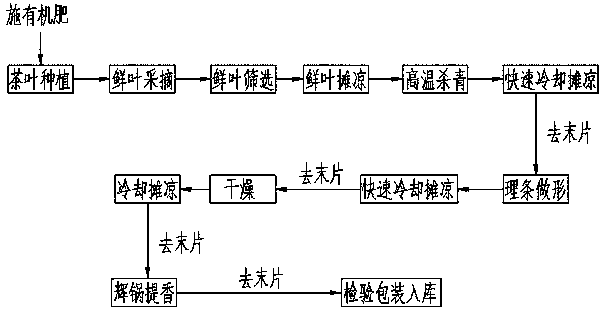

Method used

Image

Examples

Embodiment Construction

[0028] In order to more clearly understand the purpose, technical solutions and beneficial effects of the present invention, the following specific examples will be used to further illustrate the present invention, but the protection scope of the present invention is not limited to the following examples.

[0029] 1. Tea tree planting

[0030] The tea trees used in the present invention are planted in southern Sichuan, and the best planting area is Jinfeng Mountain in Luzhou.

[0031] Combining tung fruit husk with rapeseed, plant ash, and farmyard manure in a mass ratio of 1:1:1:2 to ferment for 30-35 days to obtain an organic fertilizer, the mass ratio of nitrogen, potassium, and phosphorus in the obtained organic fertilizer can reach N: P: K=2:1:1, according to the characteristics of soil and climatic conditions in southern Sichuan, by analyzing the difference in the content of fertility components in the soil, the above-mentioned organic fertilizers are deeply buried near ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com