Multi-level combined type secondary distillation heat control ultrapure water continuous generator

A technology of heating adjustment and distiller, which is applied in the direction of heating water/sewage treatment, non-polluting water treatment, etc., and can solve the problems of continuous replenishment of liquid, water purifiers burning dry and cracking, and difficult high-purity water quality, etc., to improve cooling efficiency , reduce consumption and save water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

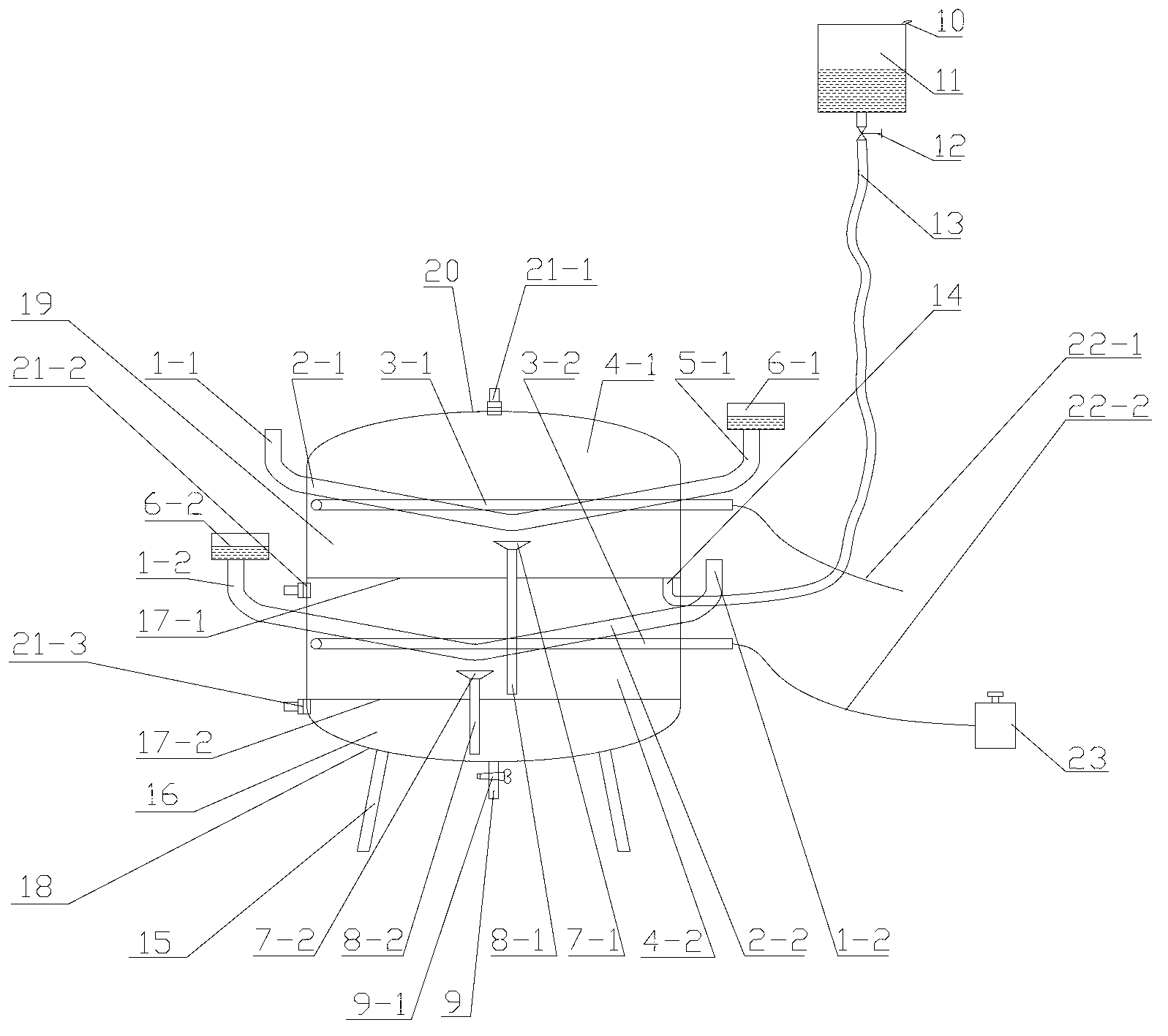

[0053] 1. Multi-stage combined secondary distillation heating and regulating ultrapure water continuous generator, including primary condenser outlet pipe 1-1, primary V-shaped condenser pipe 2-1, primary quartz heating pipe 3-1, and primary distiller 4- 1. Primary condenser inlet pipe 5-1, primary condenser inlet pipe water seal 6-1, primary liquid receiving funnel 7-1, primary funnel neck 8-1, secondary condenser outlet pipe 1-2, secondary V Condenser tube 2-2, secondary quartz heating tube 3-2, secondary distiller 4-2, secondary condensing tube inlet tube 5-2, secondary condensing tube inlet tube water seal 6-2, secondary liquid bearing Funnel 7-2, secondary funnel neck 8-2, high-purity water outlet pipe 9, quartz glass valve 9-1, pressure balance hole 10, high-level glass tank 11, glass valve 12, primary distilled water inlet hose 13, primary distilled water inlet Liquid port 14, bracket 15, high-purity water storage chamber 16, upper interlayer 17-1, lower interlayer 17-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com