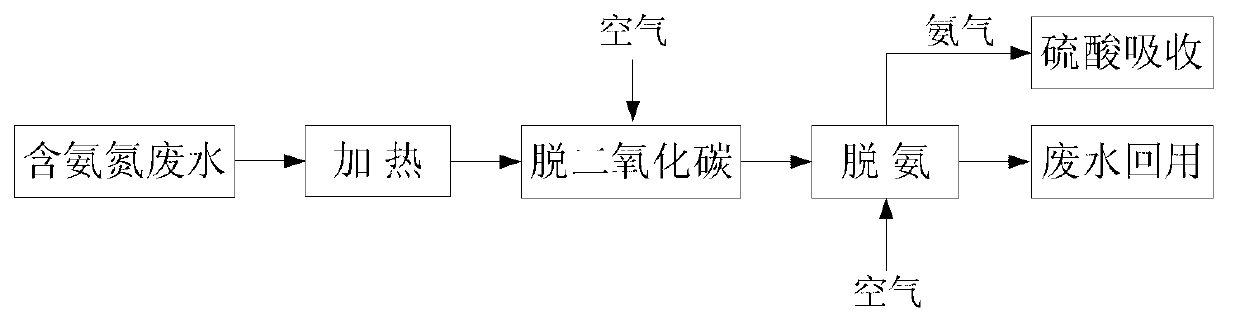

Method for removing ammonia nitrogen from anaerobic digestion effluent

An anaerobic digestion and carbon dioxide removal technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as process influence, chemical addition, environmental pollution, etc. Ammonia cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: cassava distiller's grains anaerobic digestion effluent, total volume 100m 3 , the alkalinity is 3570mg / L, with CaCO 3 The concentration of ammonia nitrogen is 570mg / L, the temperature is directly heated to 40°C by steam with a pressure of 3atm, and air is introduced into the decarbonation tank for aeration, and the air flow rate is 5000m 3 / h, stop aeration after the pH of the anaerobic digestion effluent rises to 9.15. After the decarbonization is completed, the anaerobic digestion effluent is pumped into the stripping tower with a flow rate of 25m 3 / h, the blowing off tower is a plate tower, and the blowing off air volume is 125000m 3 / h, after a stripping tower, the removal rate of ammonia nitrogen reaches 50%. The anaerobic digestion effluent after this deammonification is used as batching water for alcoholic fermentation, and alcohol concentration is 11.89 ± 0.05% (v / v) when fermentation finishes, and the obtained fermentation result of batching ...

Embodiment 2

[0022] Embodiment 2: cassava distiller's grains anaerobic digestion effluent, total volume 100m 3 , the alkalinity is 3340mg / L, with CaCO 3 According to the calculation, the ammonia nitrogen concentration is 548mg / L. In the finned tube heat exchanger, the high-temperature flue gas with a temperature of 450°C is used to exchange heat to 70°C. Treatment, air flow of 100m during decarburization 3 / h until the pH rises to 9.46. After decarbonization, the anaerobic digestion effluent is pumped into the deammonization tower, and the feed flow rate is controlled to 20m 3 / h, the stripping tower is a packed tower, and the stripping air volume is 20000m 3 / h, after a stripping tower, the removal rate of ammonia nitrogen reaches 76%. The anaerobic digestion effluent after this deamination is used as batching water for alcoholic fermentation, and alcohol concentration is 11.95 ± 0.13% (v / v) when fermentation finishes, and the obtained fermentation result of batching with tap water is...

Embodiment 3

[0023] Embodiment 3: cassava distiller's grains anaerobic digestion effluent, total volume 300m 3 , the alkalinity is 3980mg / L, with CaCO 3 According to the calculation, the concentration of ammonia nitrogen is 773mg / L. In the shell and tube heat exchanger, the waste liquid of alcohol distillation at 90°C is used to exchange heat to make the temperature reach 50°C. The flow rate is 9000m 3 / h until the pH rises to 9.32. After the decarbonization is completed, the anaerobic digestion effluent is pumped into the deammonization tower with a flow rate of 50m 3 / h, the deamination tower is a plate tower, and the blowing air volume is 100000m 3 / h, after one stripping, the removal rate of ammonia nitrogen reaches 63%. The deammoniated anaerobic digestion effluent is used as ingredient water for alcoholic fermentation, and the alcohol concentration at the end of fermentation is 11.76±0.04% (v / v), which is equivalent to the fermentation result obtained from tap water ingredients (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com