Reciprocating Drilling Machine

A technology of drilling machine and impact mechanism, which is applied in the field of reciprocating direct impact drilling machine, which can solve the problems of high kinetic energy absorption consumption of reciprocating impact, reduced drilling force of drill bit, and weakened forward propulsion force, etc., so as to improve the impact life , reduce replacement and maintenance, and improve the effect of block granularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

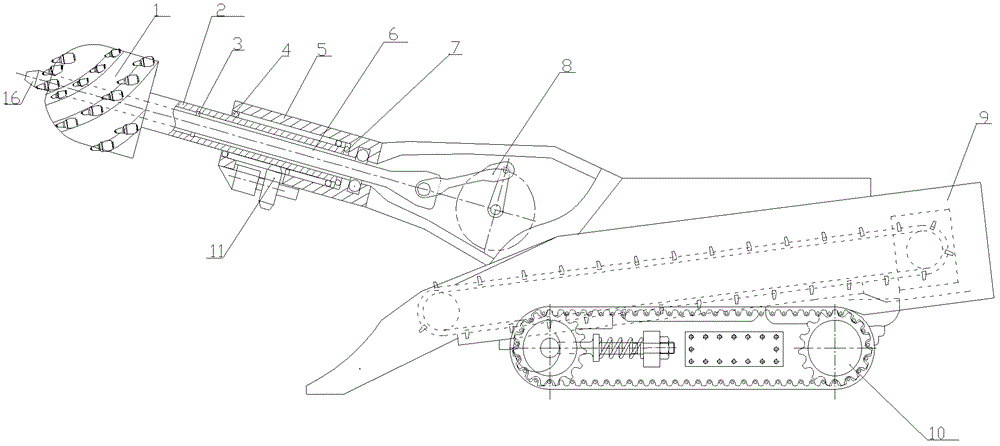

[0047] figure 1 It is the reciprocating boring machine described in Example 1. The equipment includes a fuselage 9 and the like. The fuselage includes a walking mechanism 10 and the like. The walking mechanism 10 drives the whole machine to walk. The reciprocating direct drilling machine also includes an impact mechanism and a rotary drilling mechanism, etc. The impact mechanism and rotary drilling mechanism are arranged on the fuselage 9. The impact mechanism includes an impact device 8, an impact rod 6, an impact head 16, etc., the impact head 16 It is arranged at the front of the impact device 8, the impact rod 6 of the impact mechanism is arranged on the frame guide device or the like, and the impact head 16 is installed at the front of the impact rod 6. The rotary drilling mechanism includes a rotary drilling device 11, a drill bit 1, a drill rod 2, and a driver. The driver includes power components and gears. The power components are motors, etc. The power components driv...

Embodiment 2

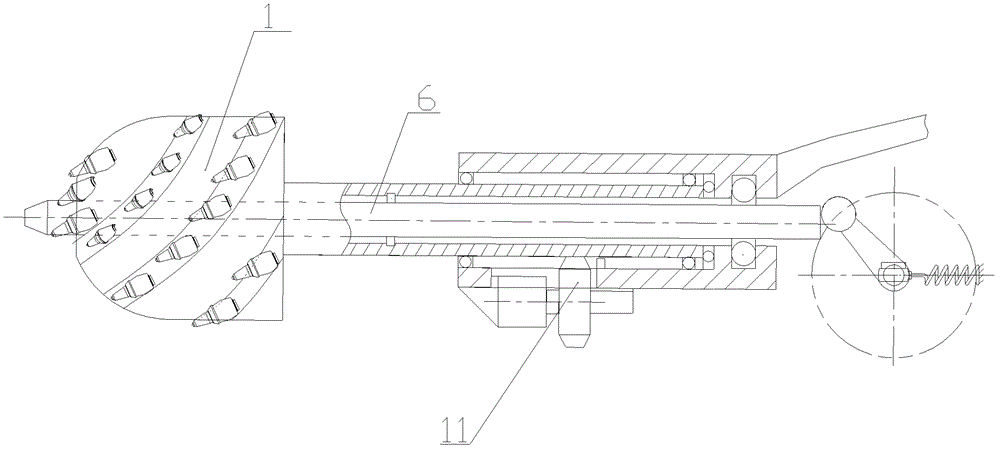

[0051] figure 2 It is the reciprocating boring machine described in Example 2. In this embodiment, the impact device is a rotary handle impact device. The rotary handle and the impact rod 6 are in a separate structure. One end of the rotary handle is fixedly connected to the drive shaft of the power component, and the other end rotates the impact impact rod, and the impact rod drives When the impact head impacts, the machine travels to block the impact head, and the rotating handle impacts again to make the impact head reciprocate.

[0052] The outer end of the rotating handle can be provided with a fixed hammer, a chain hammer, an axle hammer, a spring hammer, a rubber arm hammer or a polyester arm hammer.

[0053] A buffer device is provided on one side of the drive shaft of the power component, or a buffer device may not be provided.

[0054] Others are the same as in Example 1.

Embodiment 3

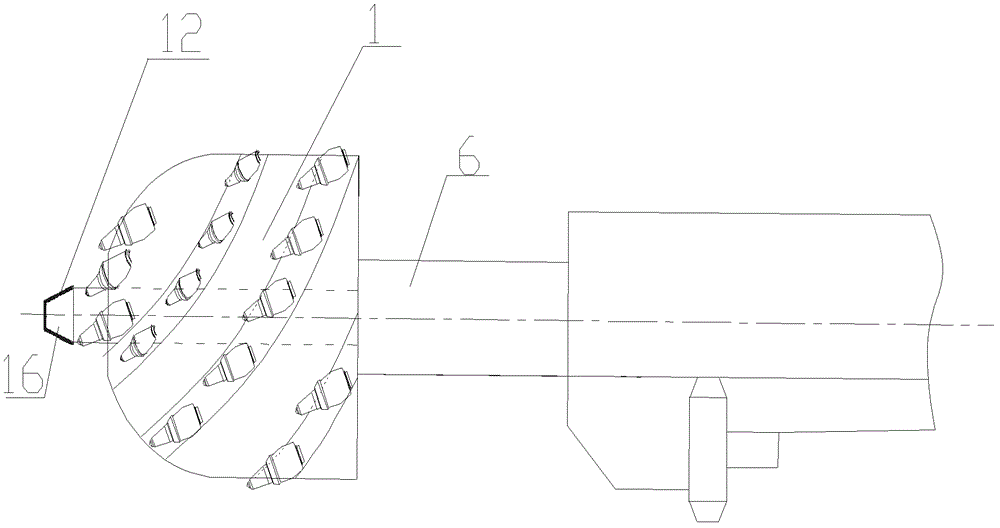

[0056] image 3 It is the reciprocating boring machine described in Example 3. In this embodiment, the head of the impact head 16 is provided with impact resistant alloy steel 12, and the head of the drill bit 1 is provided with wear resistant alloy steel.

[0057] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com