Lithium-sulfur battery cathode material capable of restricting polysulfide dissolution, electrode slice and battery

A technology for lithium-sulfur batteries and cathode materials, applied in the field of lithium-ion batteries, can solve the problems of limiting the specific capacity of carbon-sulfur composite cathode materials and low specific capacity of composite materials, and achieve excellent cycle stability, high specific capacity, and good cycle stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Lithium-sulfur battery positive electrode material is composed of porous carbon and sulfur, in which the porous carbon has a "shell-core" structure, the inner "core" structure is an ordered mesoporous carbon with a pore size of 10nm, and the outer "shell" structure It is microporous carbon with a pore diameter of 0.4nm, sulfur is evenly distributed in the porous carbon, and the mass ratio of porous carbon to sulfur is 5:5.

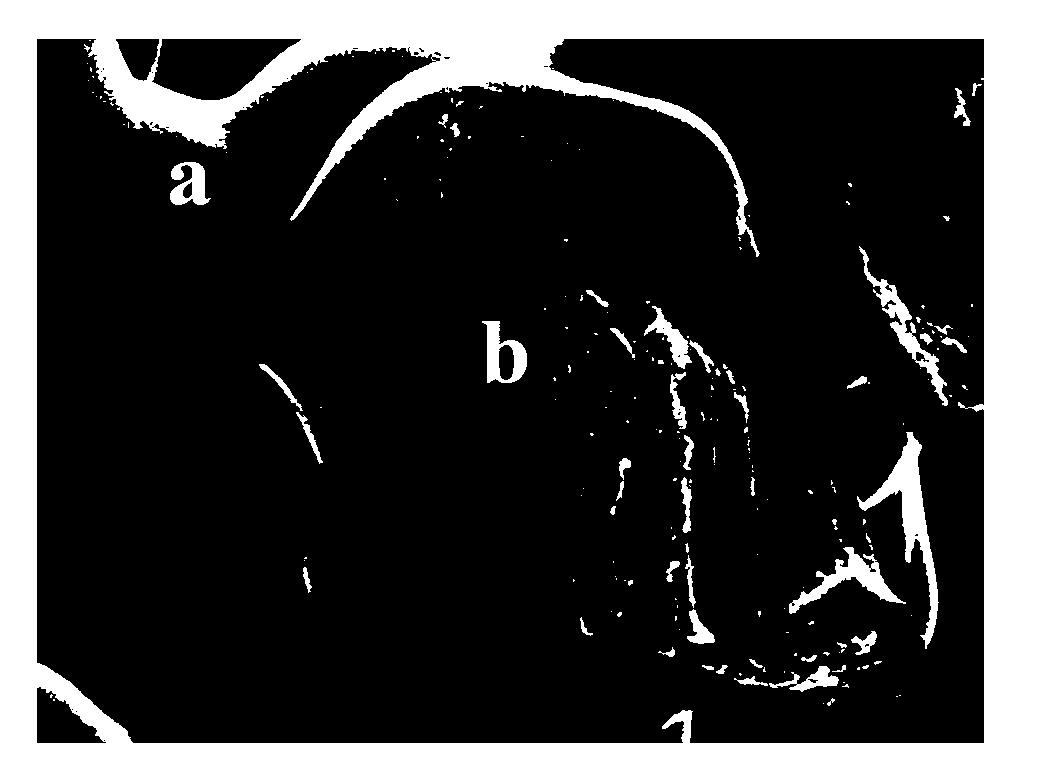

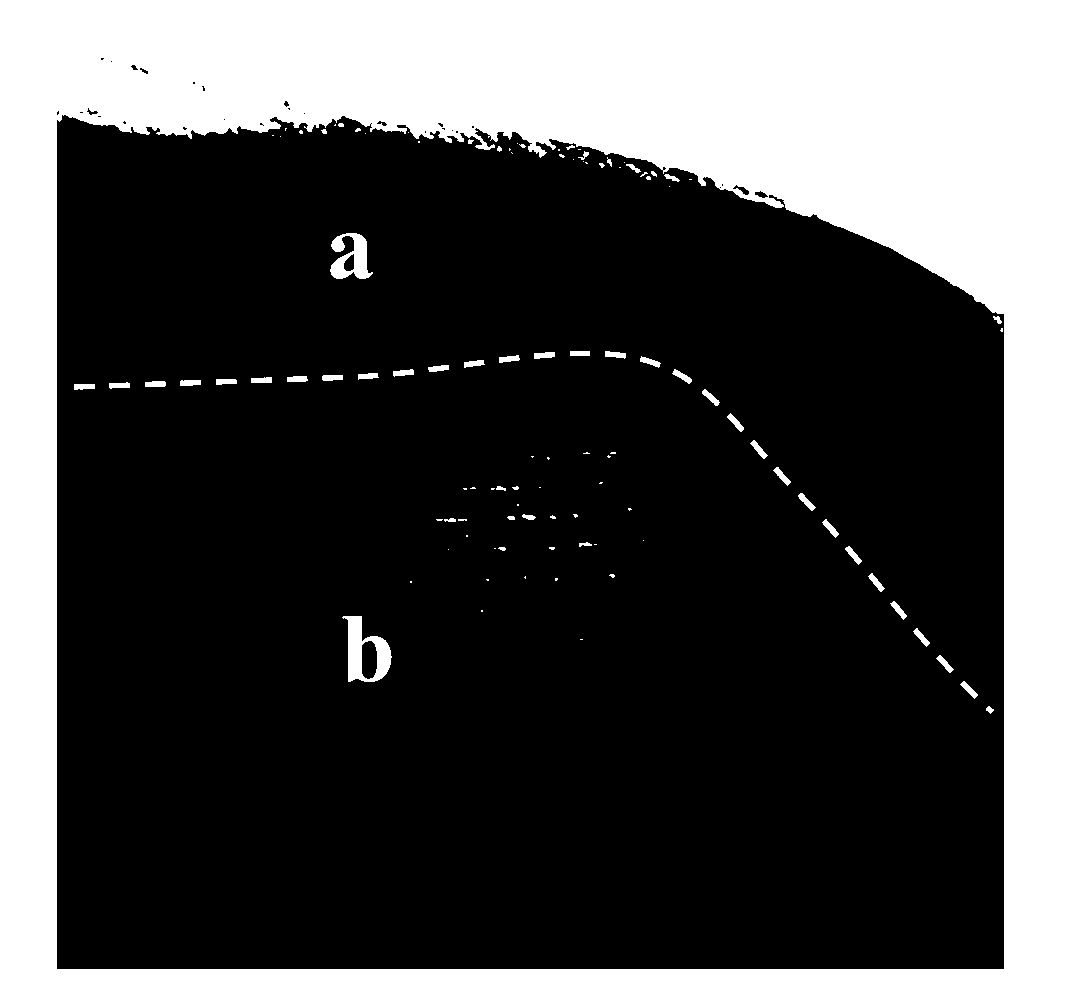

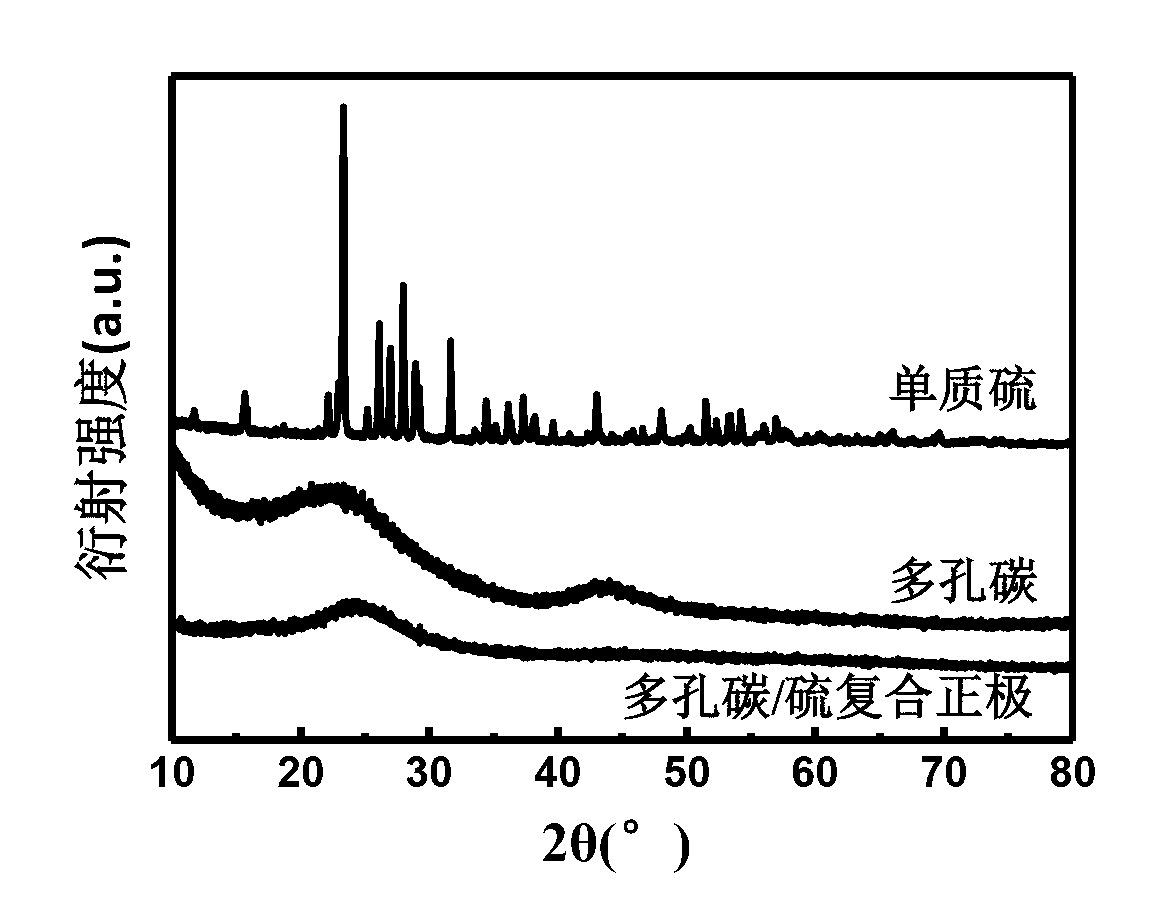

[0028] figure 1 It is the SEM figure of the porous carbon in embodiment 1, can see mesoporous carbon structure (see figure 1 The exterior of b) is covered with a certain thickness of microporous carbon structure (see figure 1 A) shows that the microporous carbon structure is uniformly coated on the outside of the mesoporous carbon structure, forming the porous carbon with a core-shell structure provided by the present invention. figure 2 It is the TEM figure of embodiment 1, can see ordered mesoporous carbon structure (see figure 2 The exterior...

Embodiment 2

[0031] Lithium-sulfur battery positive electrode material is composed of porous carbon and sulfur, in which the porous carbon has a "shell-core" structure, the inner "core" structure is disordered mesoporous carbon with a pore size of 8nm, and the outer "shell" structure It is a microporous carbon with a pore diameter of 0.5nm, sulfur is evenly distributed in the porous carbon, and the mass ratio of porous carbon to sulfur is 4:6. The cathode material of the lithium-sulfur battery was made into an electrode sheet according to the same process as in Example 1, and the electrode sheet was assembled into a lithium-sulfur battery according to the same process as in Example 1.

Embodiment 3

[0033] Lithium-sulfur battery cathode material is composed of porous carbon and sulfur composite, in which the porous carbon has a "shell-core" structure, the inner "core" structure is an ordered mesoporous carbon with a pore size of 9nm, and the outer "shell" structure It is a microporous carbon with a pore diameter of 0.3nm, sulfur is evenly distributed in the porous carbon, and the mass ratio of porous carbon to sulfur is 7:3. The cathode material of the lithium-sulfur battery was made into an electrode sheet according to the same process as in Example 1, and the electrode sheet was assembled into a lithium-sulfur battery according to the same process as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com