Composite nanofiltration membrane prepared based on aliphatic sulfonate condensation product

A technology of aliphatic sulfonate and composite nanofiltration membrane, which is applied in membrane technology, semipermeable membrane separation, chemical instruments and methods, etc., to achieve the effect of cost reduction, low cost and good separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

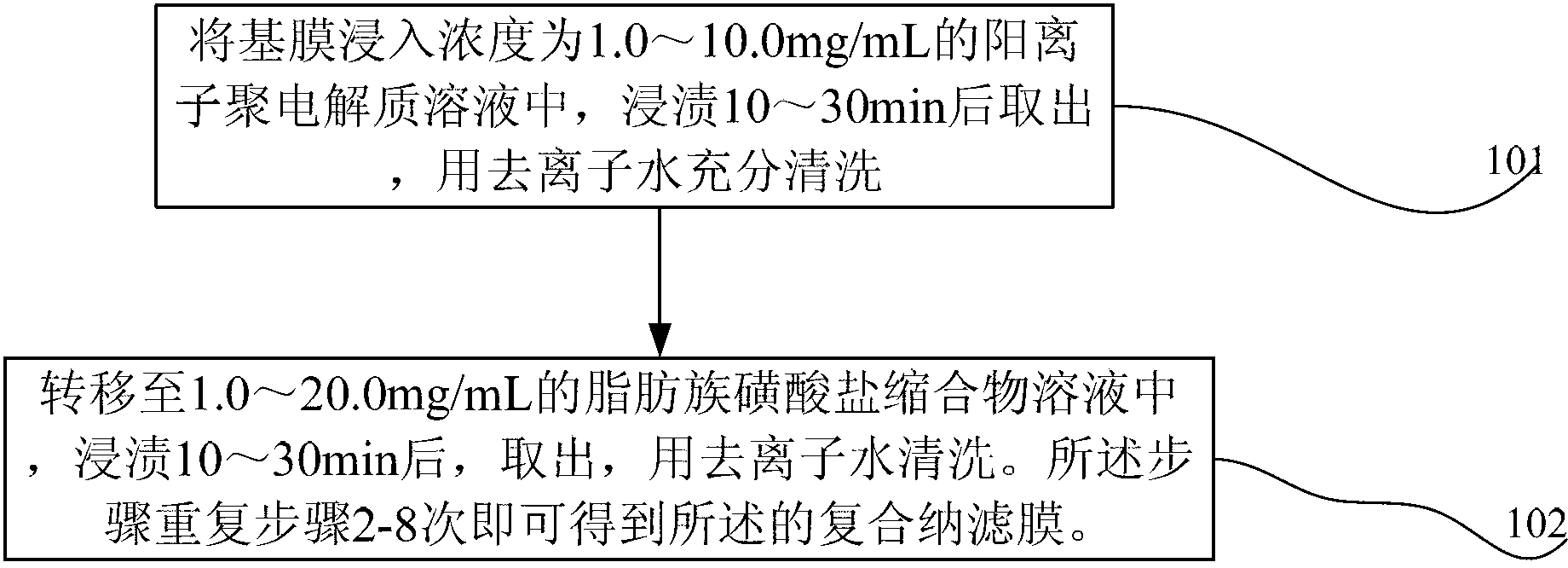

[0022] A composite nanofiltration membrane is prepared through the following steps:

[0023] Step 101: Using the polyacrylonitrile ultrafiltration membrane as the base membrane, immerse it in a polyethyleneimine polyelectrolyte solution with a concentration of 10.0 mg / mL, take it out after immersing for 10 minutes, and wash it thoroughly with deionized water;

[0024] Step 102: Transfer the membrane obtained in step 101 to a 20.0 mg / mL sulfonated cyclohexanone formaldehyde condensate solution, immerse for 10 minutes, take it out, and wash with deionized water.

[0025] Repeat the above steps twice to obtain the composite nanofiltration membrane.

Embodiment 2

[0027] A composite nanofiltration membrane is prepared through the following steps:

[0028] Step 101: Using the cellulose acetate ultrafiltration membrane as the base membrane, immerse it in a polyethyleneimine polyelectrolyte solution with a concentration of 1.0 mg / mL, take it out after immersing for 30 minutes, and wash it thoroughly with deionized water;

[0029] Step 102: Transfer the membrane obtained in step 101 to a 1.0 mg / mL sulfonated cyclohexanone formaldehyde condensate solution, immerse it for 30 minutes, take it out, and wash with deionized water.

[0030] Repeat the above steps 8 times to obtain the composite nanofiltration membrane.

Embodiment 3

[0032] A composite nanofiltration membrane is prepared through the following steps:

[0033] Step 101: Take the polyacrylonitrile ultrafiltration membrane as the base membrane, immerse it in a polyethyleneimine polyelectrolyte solution with a concentration of 5.0 mg / mL, take it out after immersing for 20 minutes, and rinse it fully with deionized water;

[0034] Step 102: Transfer the membrane obtained in Step 101 to a 8.0 mg / mL sulfonated cyclohexanone formaldehyde condensate solution, immerse it for 15 minutes, take it out, and rinse with deionized water.

[0035] Repeat the above steps 5 times to obtain the composite nanofiltration membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com