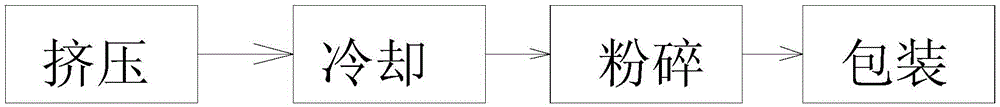

A kind of granulation process of amino molding compound granules

An amino molding compound and granule technology, which is applied in the field of granulation process of amino molding compound granules, can solve the problems of unstable physical properties, many chemical volatiles, and volatile fluidity, etc., and achieves the protection of physical properties, high strength, extended shelf life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1. The compound curing agent added in the kneading process of the present invention is a combination of curing agent D and ammonium chloride, the content ratio of curing agent D to ammonium chloride is 1.5, and the added insulation enhancer is rubber powder For the mixture with alkaline short fiber, the content ratio of rubber powder and alkaline short fiber is 0.8, the kneading temperature of the screw extruder is controlled at 80℃-115℃, and the kneading temperature of the roll mill is controlled at 45℃-70℃. The time is 1.5h, the kneaded product is dried in the drying process, and the drying temperature is controlled to be 90°C-100°C and the water content is about 4%.

Embodiment 2

[0028] In Example 2, the compound curing agent added in the kneading process of the present invention is a composition of phthalic acid and ammonium chloride, the content ratio of phthalic acid to ammonium chloride is 1.5, and the added insulation enhancer is The mixture of silicon powder and alkaline short fiber, the content ratio of silicon powder and alkaline short fiber is 0.8, the kneading temperature of the screw extruder is controlled at 80℃-115℃, and the kneading temperature of the roll mill is controlled at 45℃-70℃ , The kneading time is 1.5h, the kneading product is dried in the drying process, the drying temperature is controlled to be 90℃-100℃, and the water content is about 4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com