Preparation method of phosphoric acid three (1-chloro-2-propyl) ester

A production method and phosphoric acid technology, applied in the field of flame retardants, can solve problems such as large differences and lack of comparability, and achieve the effects of high production efficiency, environmental friendliness, and few steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In conjunction with the following embodiments, the following embodiments are illustrative and not restrictive. The following embodiments cannot be used to limit the protection scope of the present invention.

[0021] The production method of tris(1-chloro-2-propyl) phosphate, the steps are as follows:

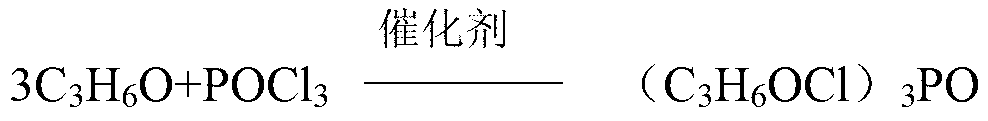

[0022] Routing

[0023]

[0024] Specific steps are as follows:

[0025] ⑴ Ingredients: Pump a quantitative amount of phosphorus oxychloride into the reaction tank with negative pressure at one time, add catalyst (titanium tetrachloride or sodium metasilicate), and use nitrogen to press the quantitative amount of propylene oxide into the high-level metering tank;

[0026] Ingredient ratio: Phosphorus oxychloride: Propylene oxide: Titanium tetrachloride = 500kg: 610kg: 500 ml (about 0.86kg), the amount of sodium metaaluminate is phosphorus oxychloride weight × 0.15wt%;

[0027] Propylene oxide and phosphorus oxychloride are used as starting materials, and the molar ratio of phosphor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com