Optical cable metal belt moving vehicle

A technology for metal belts and trucks, applied in the direction of lifting devices, etc., can solve the problems of smashing operators, consuming a lot of physical strength, and high work intensity, so as to prevent scratches or smashes, reduce labor, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

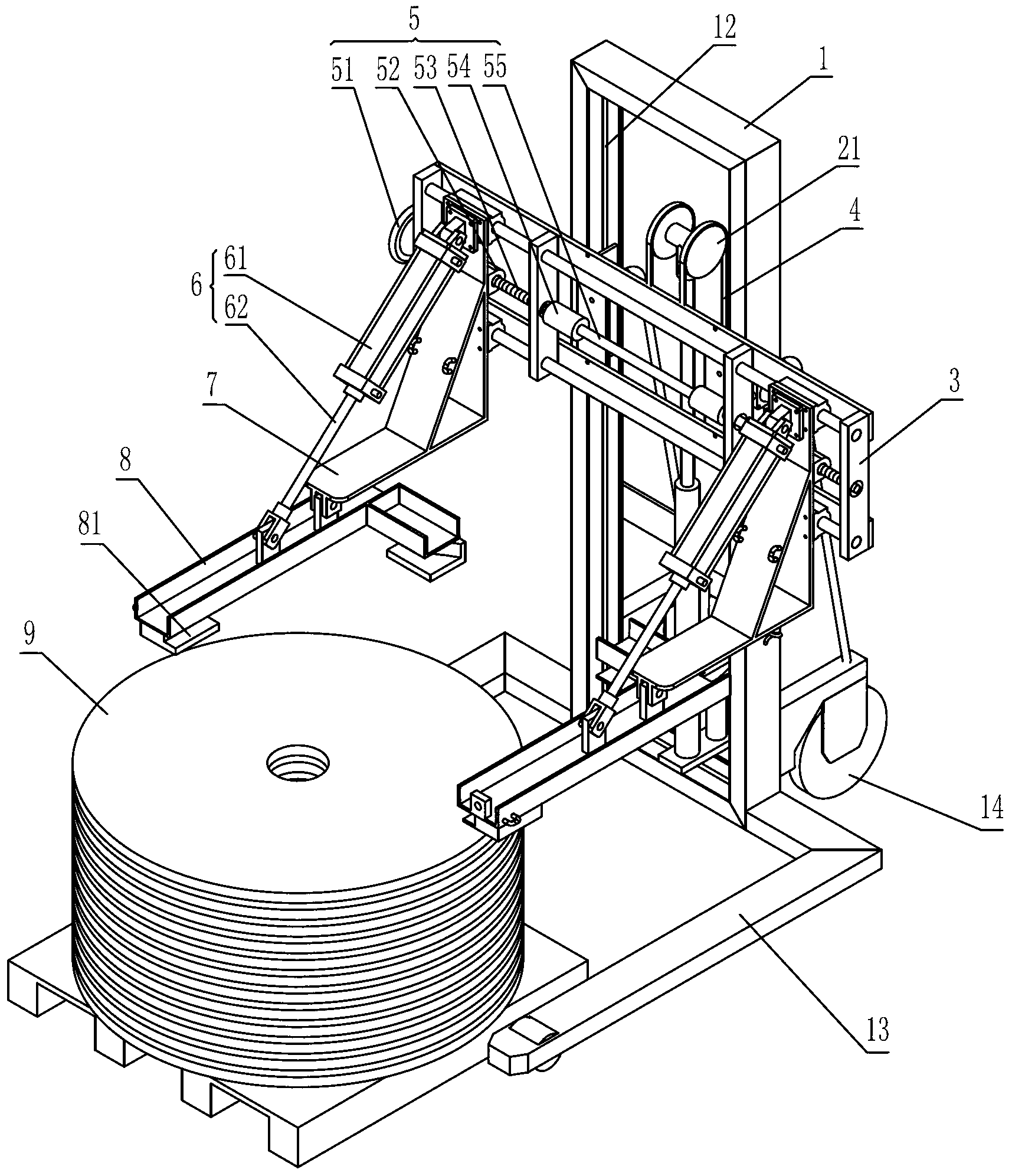

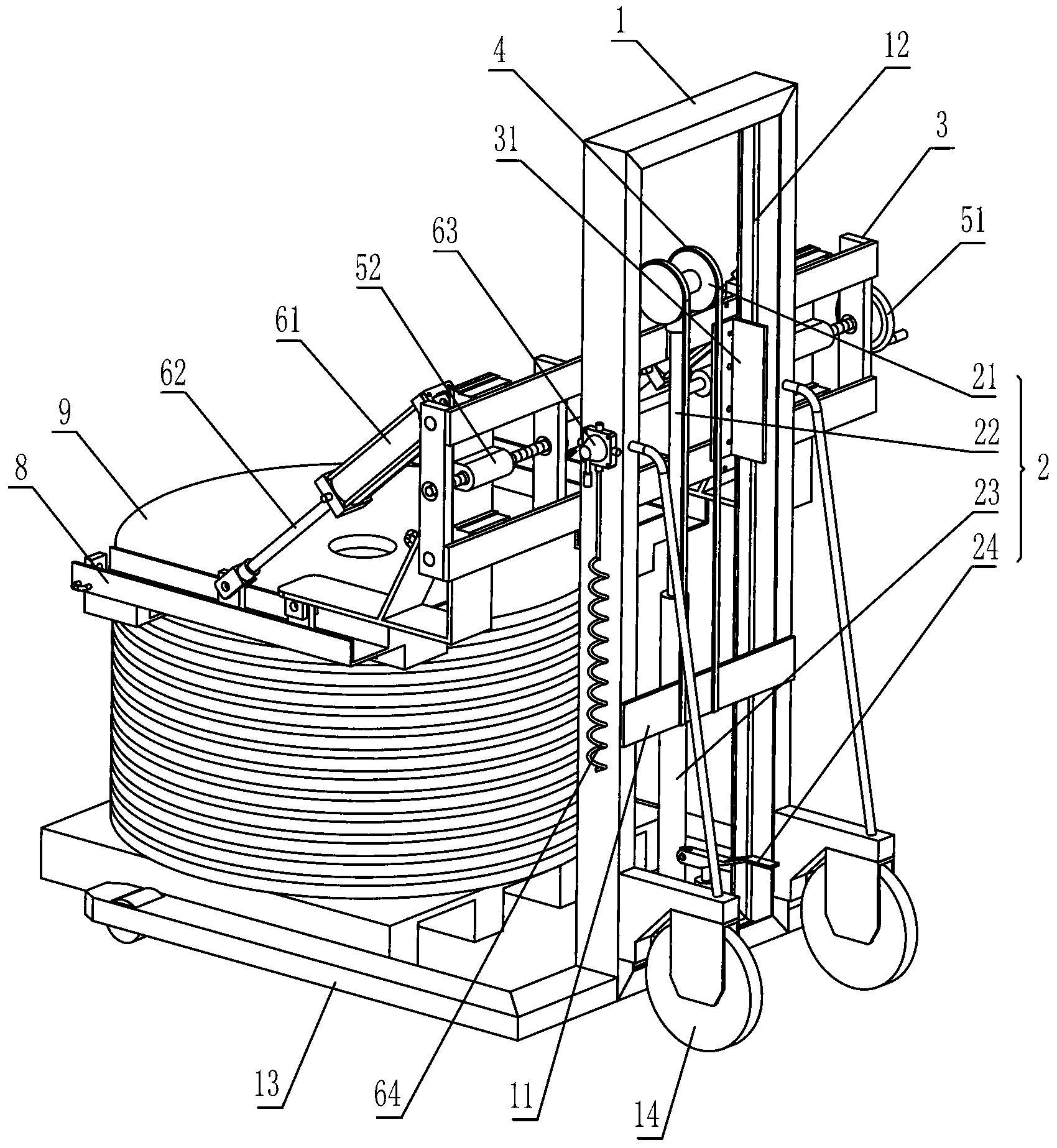

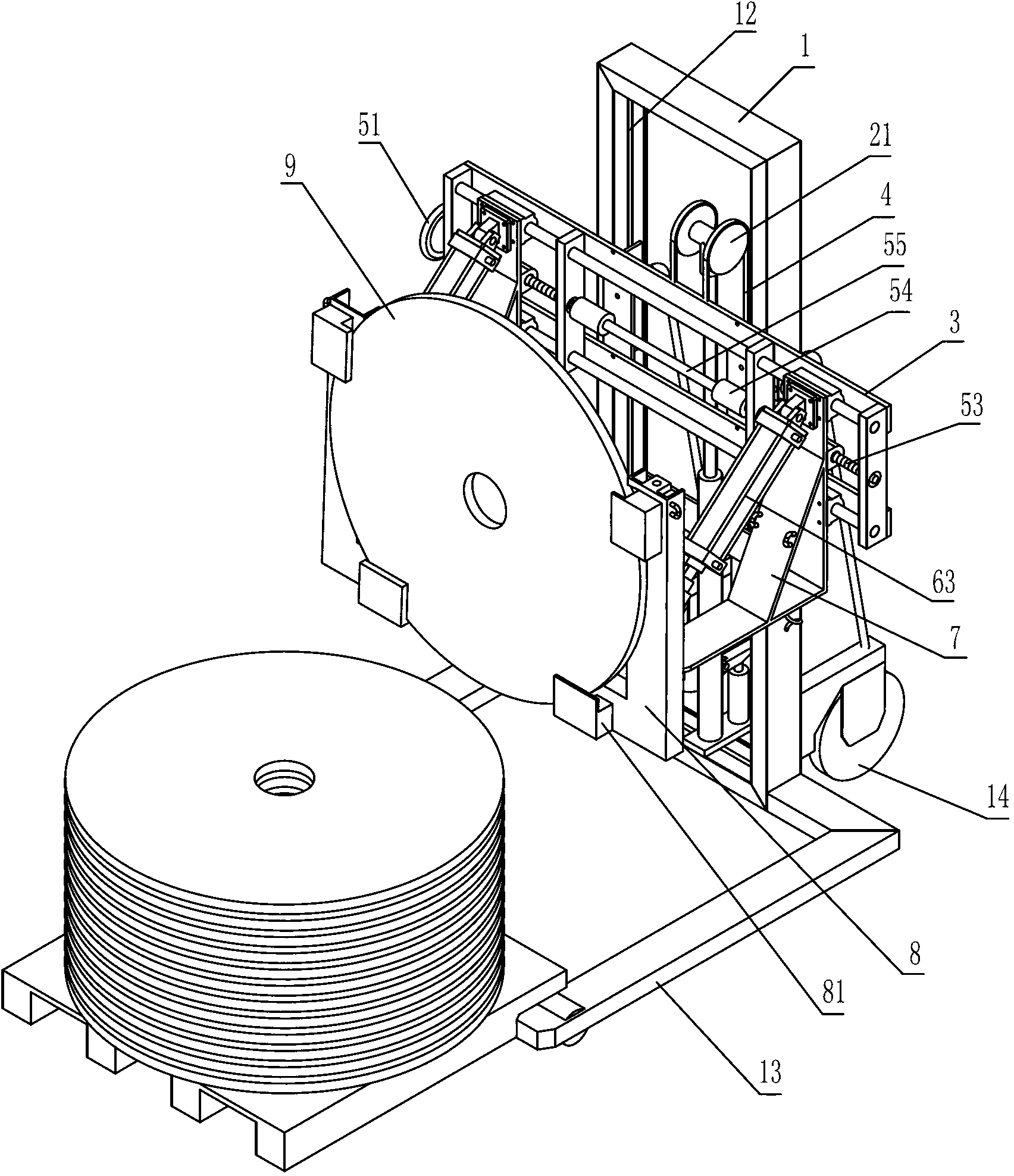

[0022] Such as figure 1 and figure 2 As shown, the optical cable metal belt transport vehicle of the present invention includes a mobile frame 1, a hydraulic transmission device 2, a clamping frame 3, a connecting chain 4, a manual transmission device 5, two pneumatic transmission devices 6 and a pair of mounting arms 7. The bottom of the mobile frame 1 is a base 13 parallel to the bottom surface, and the front of the base 13 is open for accommodating the stacked metal strips 9 . The base 13 is provided with wheels 14 for moving, the upper part of the mobile frame 1 is a square frame, and the hydraulic transmission device 2 is longitudinally installed on the mobile frame 1, and the hydraulic transmission device 2 is installed on the square frame of the mobile frame 1 in this embodiment Inside. The hydraulic transmission device 2 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com