Method for preparing semisolid blank

A semi-solid and billet technology, which is applied in the field of semi-solid billet preparation, can solve the problems of small sample size, uneven structure and performance, etc., and achieve the effects of high deformation efficiency, uniform performance, and precise control of rolling deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

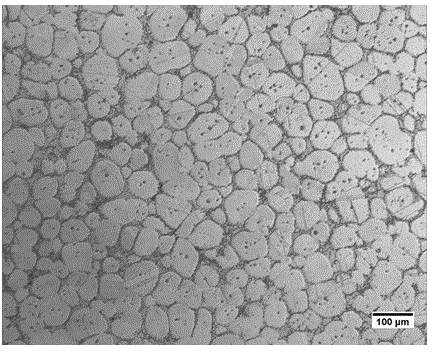

[0023] Embodiment 1: The method for preparing CuSn10 tin bronze semi-solid blanks prepared by the multi-pass rolling and remelting process of this embodiment (see figure 1 ):

[0024] (1) Measure the liquid-solid phase line point of the semi-solid blank alloy to be prepared; the alloy in this example is a CuSn10 tin bronze alloy with a rectangular material of 25×25×100mm in size, using differential scanning calorimetry (DSC) The solidus temperature of the alloy is 850℃, and the liquidus temperature is 1020℃;

[0025] (2) The alloy billet is heated to above the recrystallization temperature, and the billet is subjected to multi-directional alternating rolling of cross rolling and longitudinal rolling using the rolling process; in this embodiment, CuSn10 tin bronze is heated to 450°C, and then first Roll the billet in one pass along its axis with a reduction of 2mm; then rotate the billet 90° along its axis and roll it with a reduction of 1.5mm; then rotate the billet along its axis...

Embodiment approach 2

[0027] Embodiment 2: The rolling and remelting process of this embodiment prepares a 5083 aluminum alloy semi-solid blank preparation method:

[0028] (1) Measure the liquid-solid phase line point of the semi-solid billet alloy to be prepared; in this example, the alloy is 5083 aluminum alloy and a rectangular material with a size of 30×30×150 mm, using differential scanning calorimetry (DSC) The solidus temperature of the alloy is measured to be 571 ℃, and the liquidus temperature is 642 ℃;

[0029] (2) The alloy billet is heated to a temperature above the recrystallization temperature, and the billet is subjected to multi-directional alternating rolling of cross rolling and longitudinal rolling using the billet forging process; in this embodiment, the 5083 aluminum alloy is heated to 460°C, and then Roll the billet in one pass along its axis with a reduction of 4mm; then rotate the billet 90° along its axis and roll it with a reduction of 5mm; then rotate the billet along its axi...

Embodiment approach 3

[0031] Embodiment 3: The method for preparing CuSn10 tin bronze semi-solid billet by rolling and remelting process of this embodiment:

[0032] (1) Measure the liquid-solid phase line point of the semi-solid blank alloy to be prepared; the alloy in this example is a CuSn10 tin bronze alloy with a rectangular material of 25×25×100mm in size, using differential scanning calorimetry (DSC) The solidus temperature of the alloy is 850℃, and the liquidus temperature is 1020℃;

[0033] (2) The alloy billet is heated to above the recrystallization temperature, and the billet is subjected to multi-directional alternating rolling of cross rolling and longitudinal rolling using the rolling process; in this embodiment, CuSn10 tin bronze is heated to 450°C, and then first Roll the billet in one pass along its axis with a reduction of 1mm; then rotate the billet 90° along its axis and roll it with a reduction of 1.5mm; then rotate the billet along its axis Roll it at 90° with a reduction of 0.8m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

| solidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com