Acoustic signal based device and method for detecting gas pipeline leakages

A leak detection device, a technology for gas transmission pipelines, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of leak judgment accuracy, general simplicity, and patent overuse, to ensure integrity and safety. High sensitivity, high equipment sensitivity, and the effect of reducing the false alarm rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

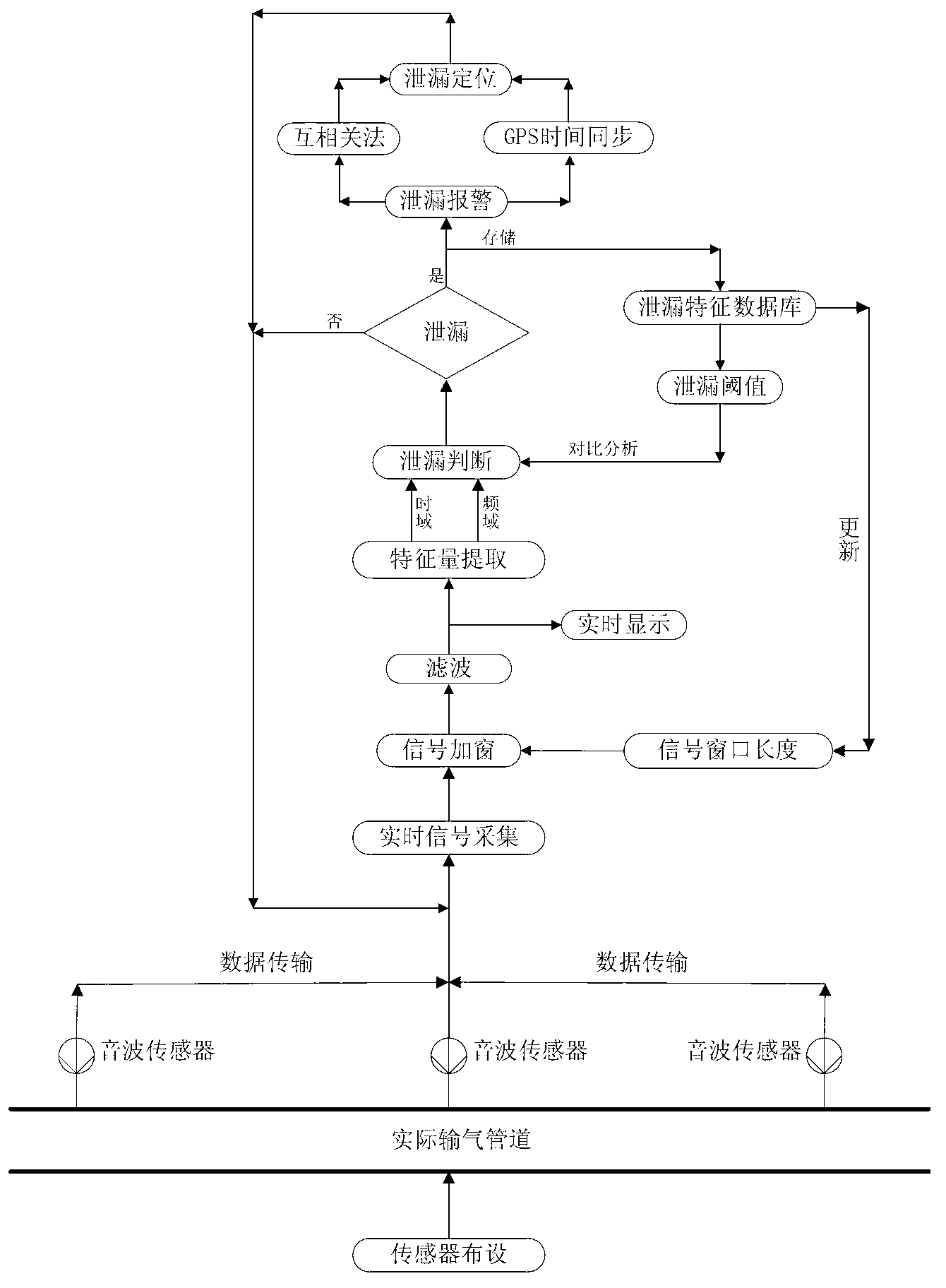

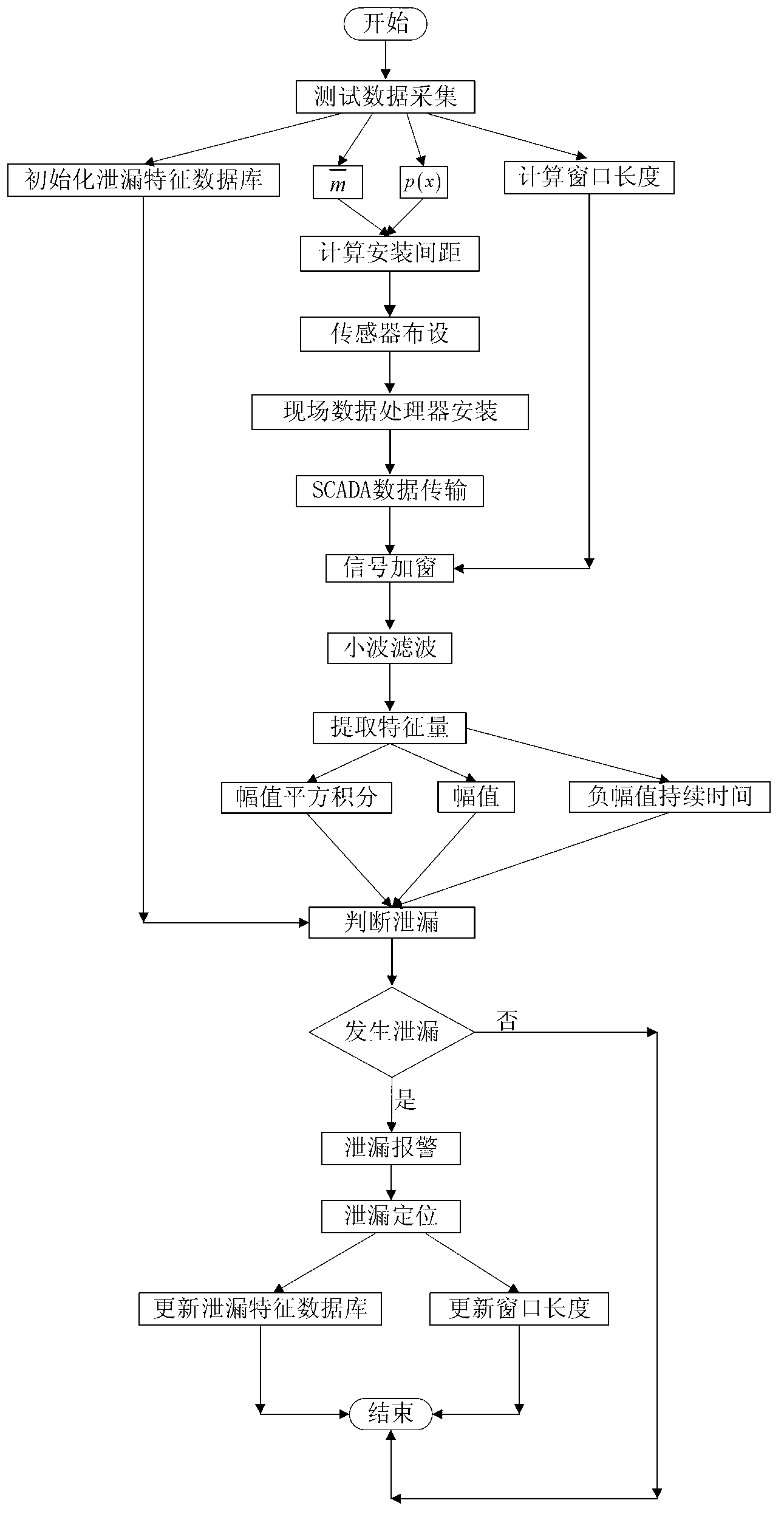

[0039] In order to make the technical solution of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

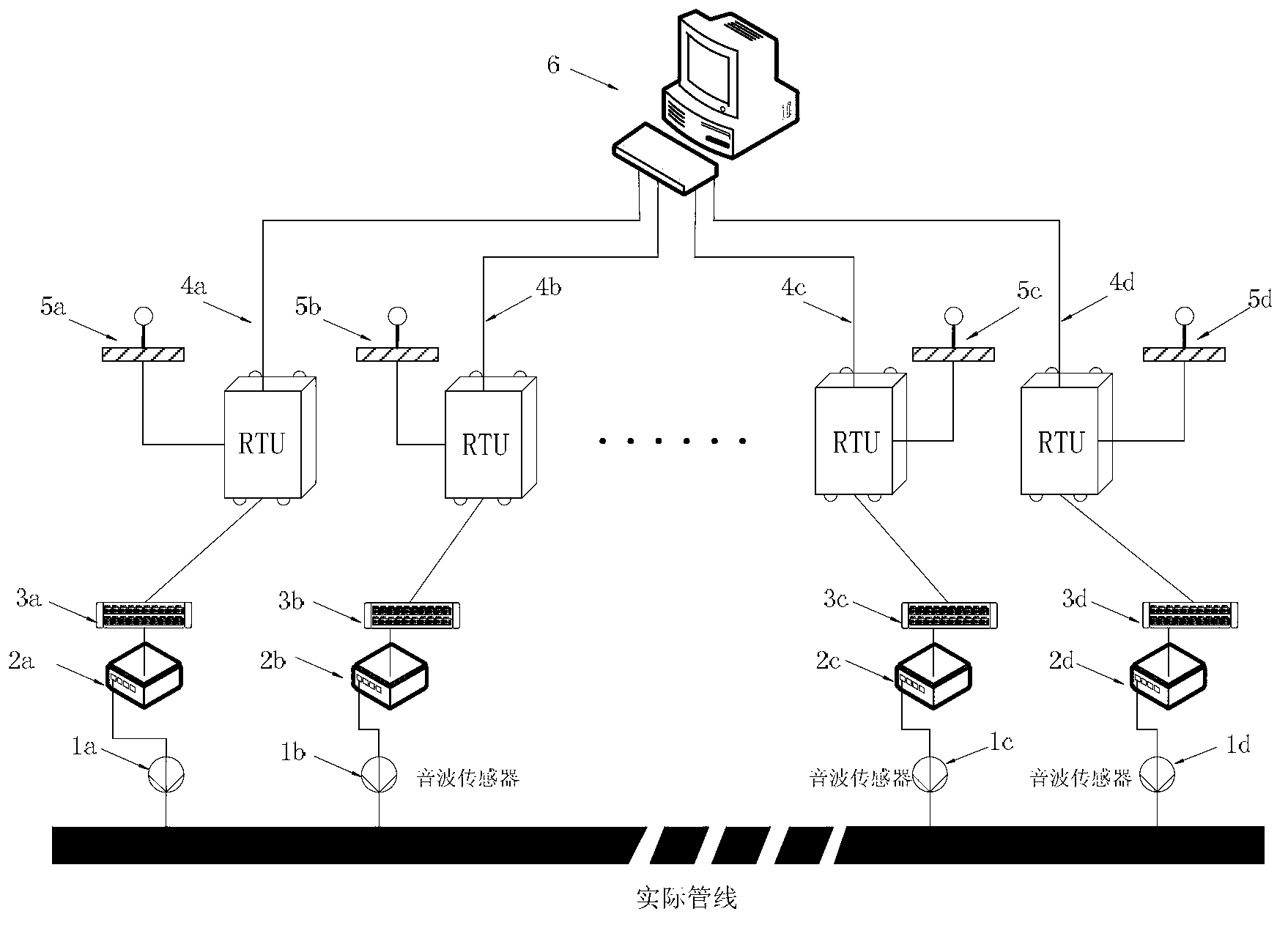

[0040] Such as figure 2 As shown, a natural gas pipeline leakage detection device based on sound wave technology, including hardware system and software system. The hardware system includes an acoustic sensor group (1a-1d), a signal conditioner (2a-2d), an analog-to-digital converter (3a-3d) and a central control computer 6 . The sound wave sensor collects the sound wave signal of the fluid in the pipe in real time. The signal conditioner supplies power to the sound wave sensor and performs signal conditioning in the early stage. The analog-to-digital converter converts the conditioned analog sound wave signal into a digital sound wave signal. After the GPS system (5a-5d) is marked with a time stamp, it relies on the SCADA system for data transmission (4a-4d), and transmits it to the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com