Pressure sensor micro-nano structure with high stability under high-temperature environment

A pressure sensor, high stability technology, applied in the field of pressure sensor micro-nano structure, can solve problems such as current leakage, signal processing system and circuit imbalance, failure, etc., achieve low temperature drift, strong anti-interference ability, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

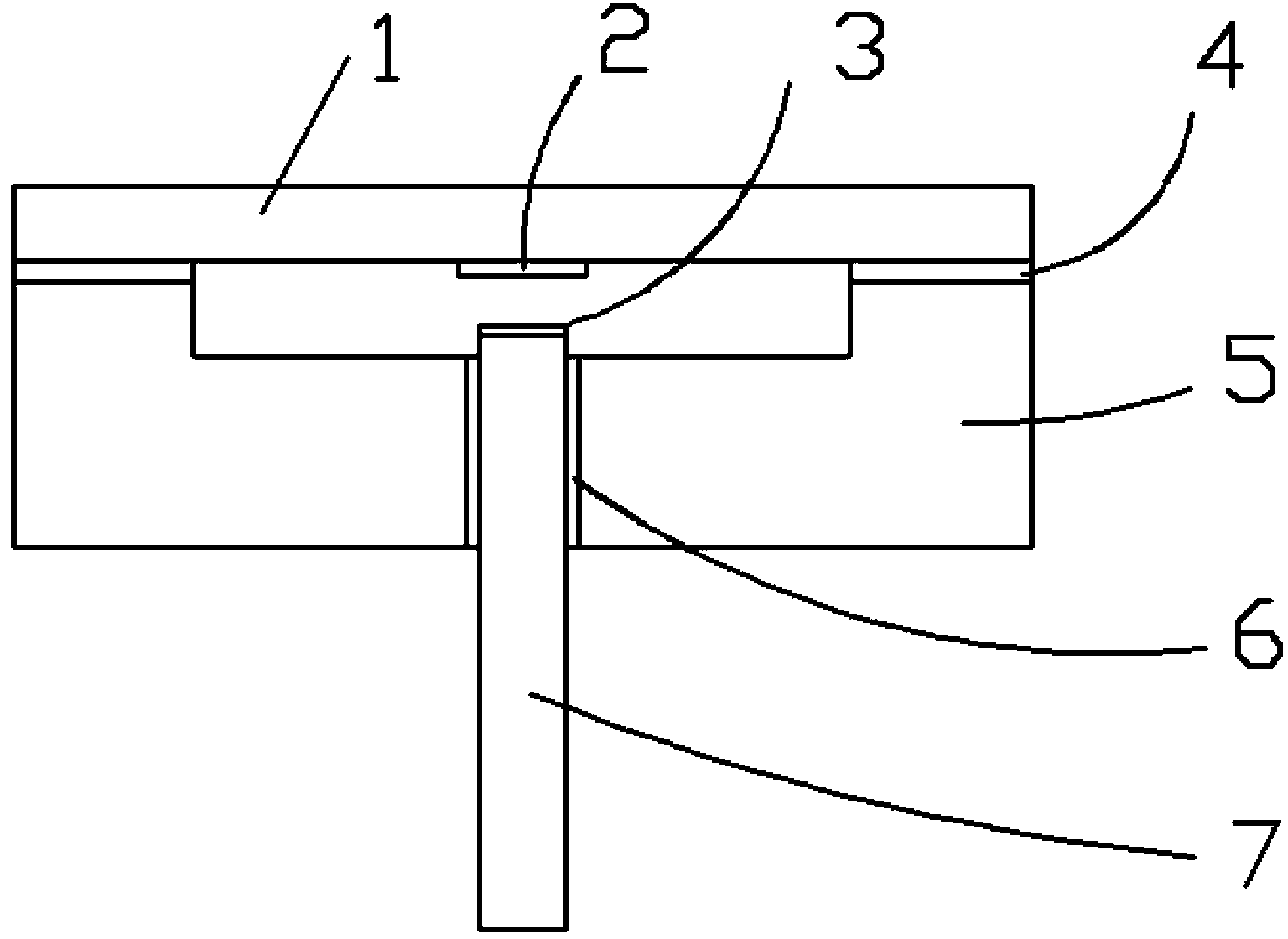

[0027] see figure 1 , the present invention is a pressure sensor micro-nano structure with high stability under high temperature environment, which includes: silicon carbide diaphragm 1, reflective film 2, semi-reflective film 3, bonding layer 4, silicon carbide substrate 5, encapsulation layer 6 and sapphire optical fiber 7; the positional connection relationship between them is: the reflective film 2 is coated on the middle part of the silicon carbide diaphragm 1, the semi-reflective film 3 is coated on the end of the sapphire optical fiber 7, and the bonding layer 4 is located between the silicon carbide diaphragm 1 and the carbonized Between the silicon substrates 5 , the sapphire optical fiber 7 is connected to the silicon carbide substrate 5 through the encapsulation layer 6 for transmitting optical signals.

[0028] The silicon carbide diaphragm 1 is a circular sheet, which will cause deformation of the diaphragm when a pressure is applied from the outside to sense the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com