Built-in high flux and large diameter laser frequency conversion device

A technology of laser frequency conversion and frequency conversion, which is applied to lasers, laser components, optics, etc., to achieve the effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

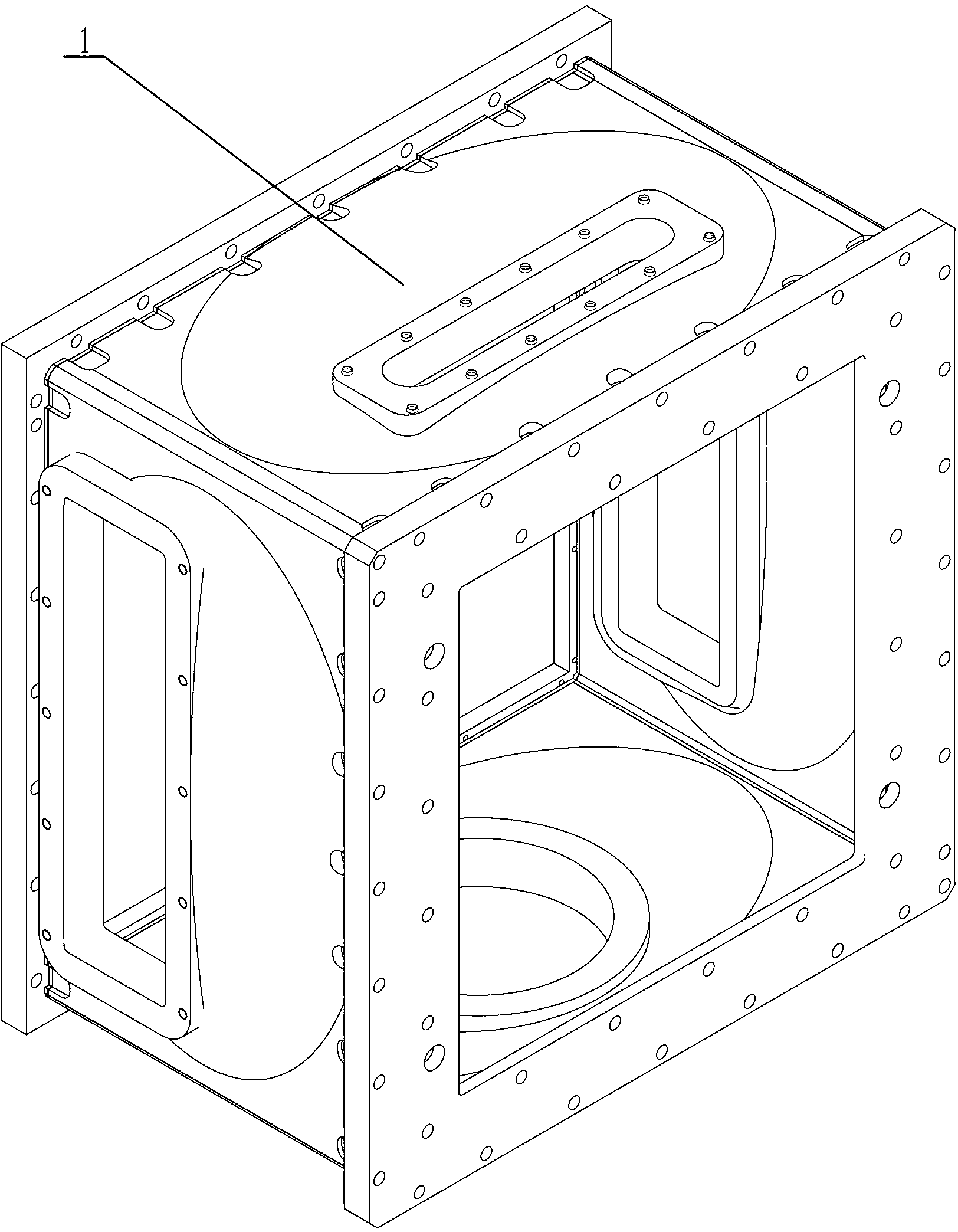

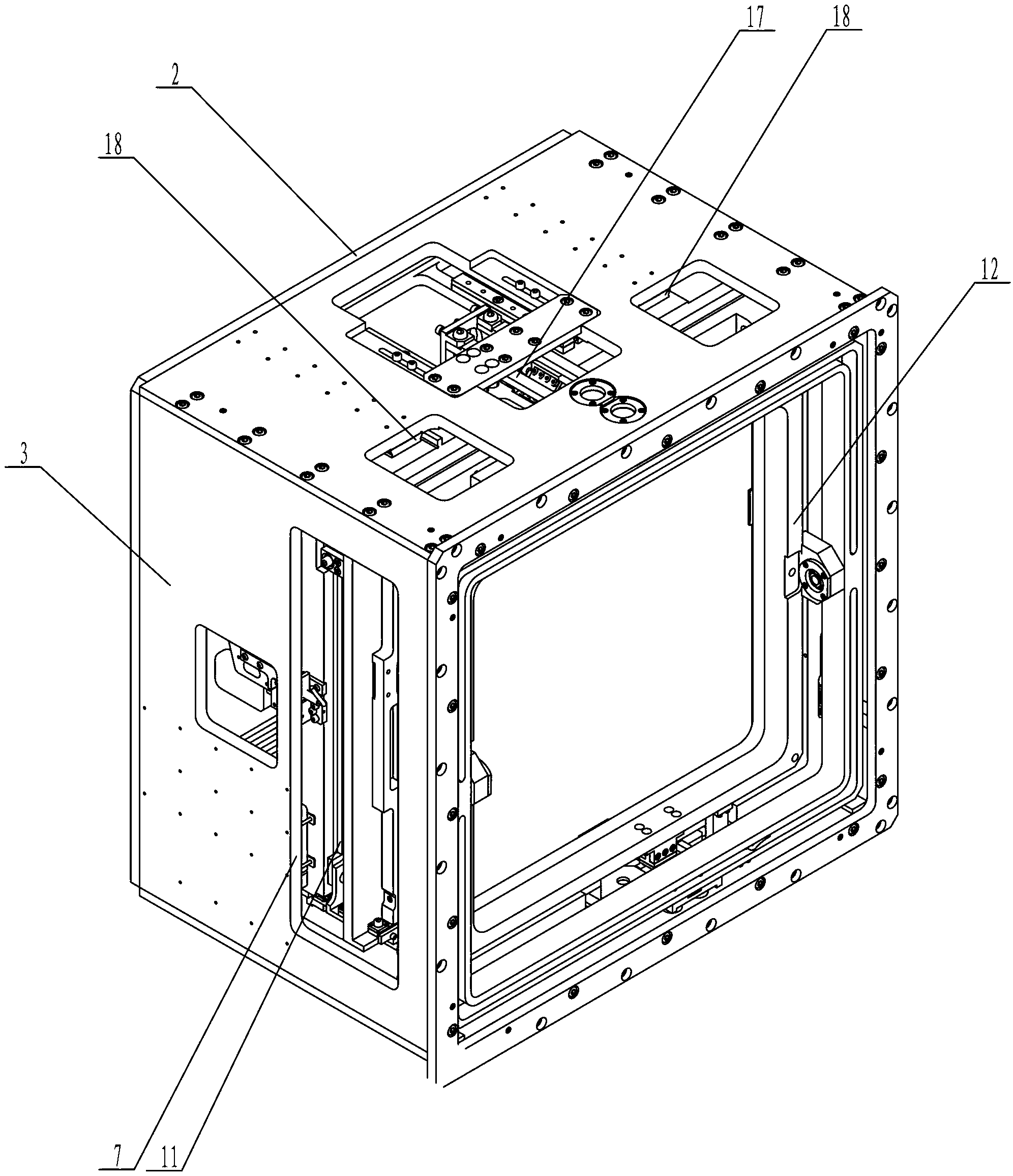

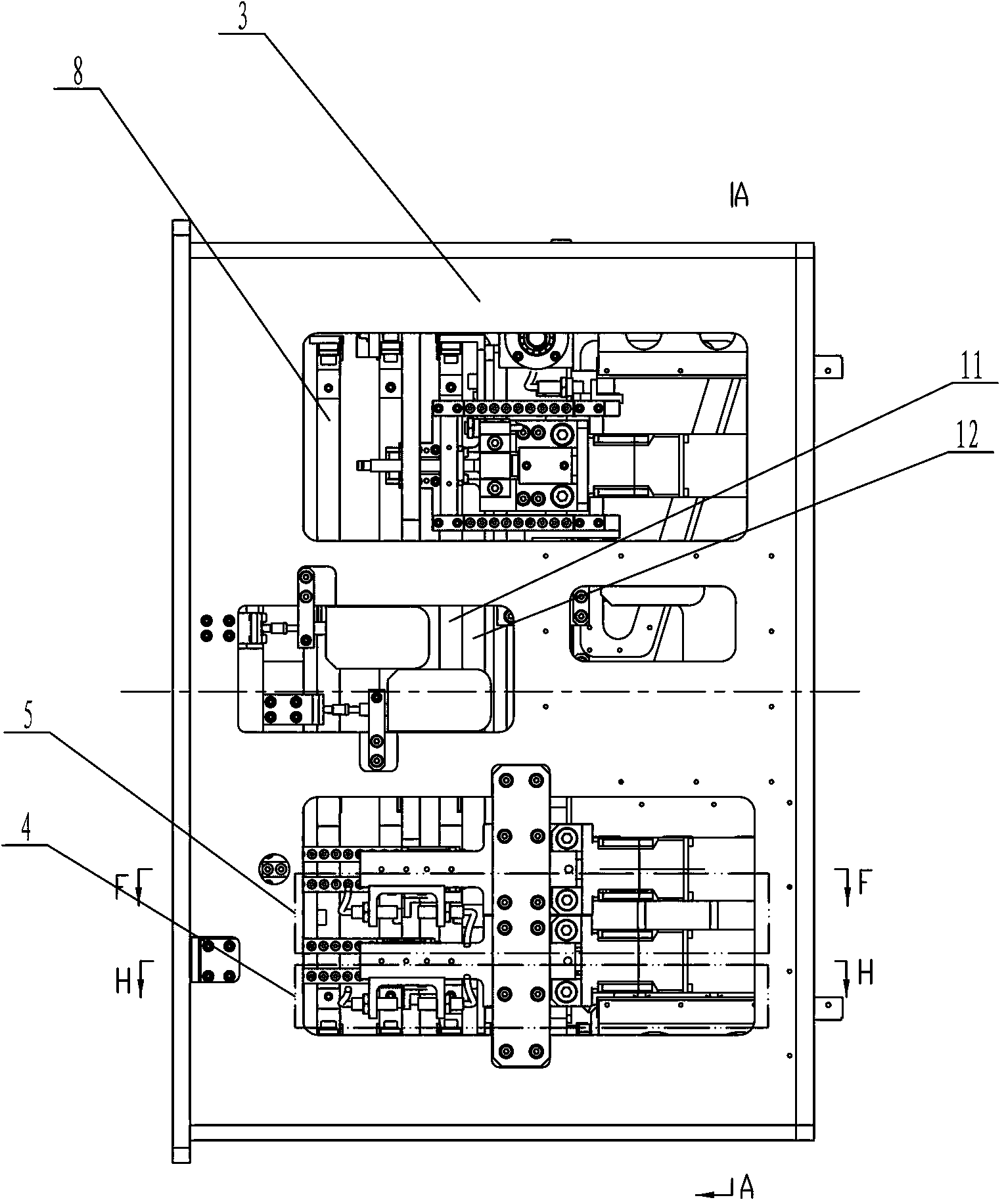

[0014] Specific implementation mode one: combine Figure 1-Figure 12 Describe this embodiment, a built-in high-throughput large-diameter laser frequency conversion device in this embodiment includes a frequency conversion module housing 1 and a frequency conversion module mechanism 2, and the frequency conversion module mechanism 2 is arranged in the frequency conversion module housing 1 ,

[0015] The frequency conversion module mechanism 2 includes a mechanism box 3, a frequency doubling angle adjustment assembly, a first frequency mixing angle adjustment assembly, a second frequency mixing angle adjustment and moving assembly, a frequency doubling first micro-drive mechanism 4, a first mixing The first micro-drive mechanism 5 of the frequency and the first micro-drive mechanism 6 of the second frequency mixing, the optical element dismounting flange window 7 is opened on the side wall of the said mechanism box 3, the first micro-drive mechanism of the frequency multiplicati...

specific Embodiment approach 2

[0024] Specific implementation mode two: combination image 3 , Figure 4 , Figure 7 , Figure 8 and Figure 10 To describe this embodiment, the frequency-multiplied first micro-drive mechanism 4 of this embodiment is a frequency-doubled yaw micro-drive mechanism, and the frequency-doubled second micro-drive mechanism 10 is a frequency-doubled pitch micro-drive mechanism. Such setting facilitates the two-dimensional adjustment of the double-frequency angle adjustment component. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Specific implementation mode three: combination image 3 , Figure 6 and Figure 11 Describe this embodiment, the first micro-drive mechanism 5 of the first frequency mixing in this embodiment is the yaw micro-drive mechanism of the first frequency mixing, and the second micro-drive mechanism 13 of the first frequency mixing is the pitching mechanism of the first frequency mixing micro drive mechanism. With such an arrangement, it is convenient to realize the two-dimensional adjustment of the first frequency mixing and angle adjustment component. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com