IT-SOFC (Intermediate Temperature Solid Oxide Fuel Cell) stack alloy connecting body and connecting method of cell stack

An IT-SOFC and connector technology, which is applied in fuel cells, fuel cell additives, battery pack components, etc., can solve the problems of difficult machining, high cost, and great differences in the corrosion path of alloy connectors. Achieve the effect of avoiding design difficulties, improving stability, reducing processing difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical method of the present invention will be further described below in conjunction with the accompanying drawings.

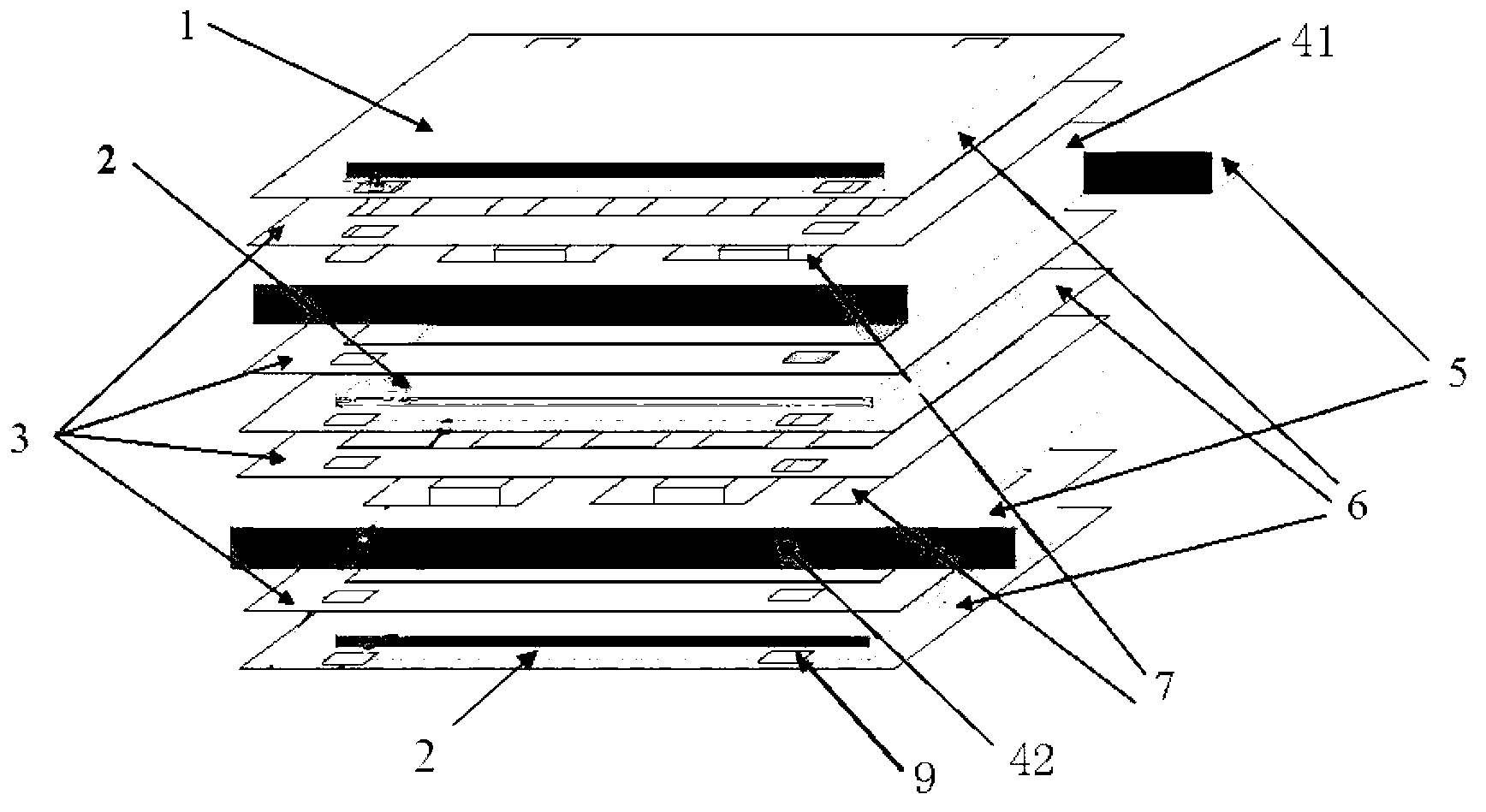

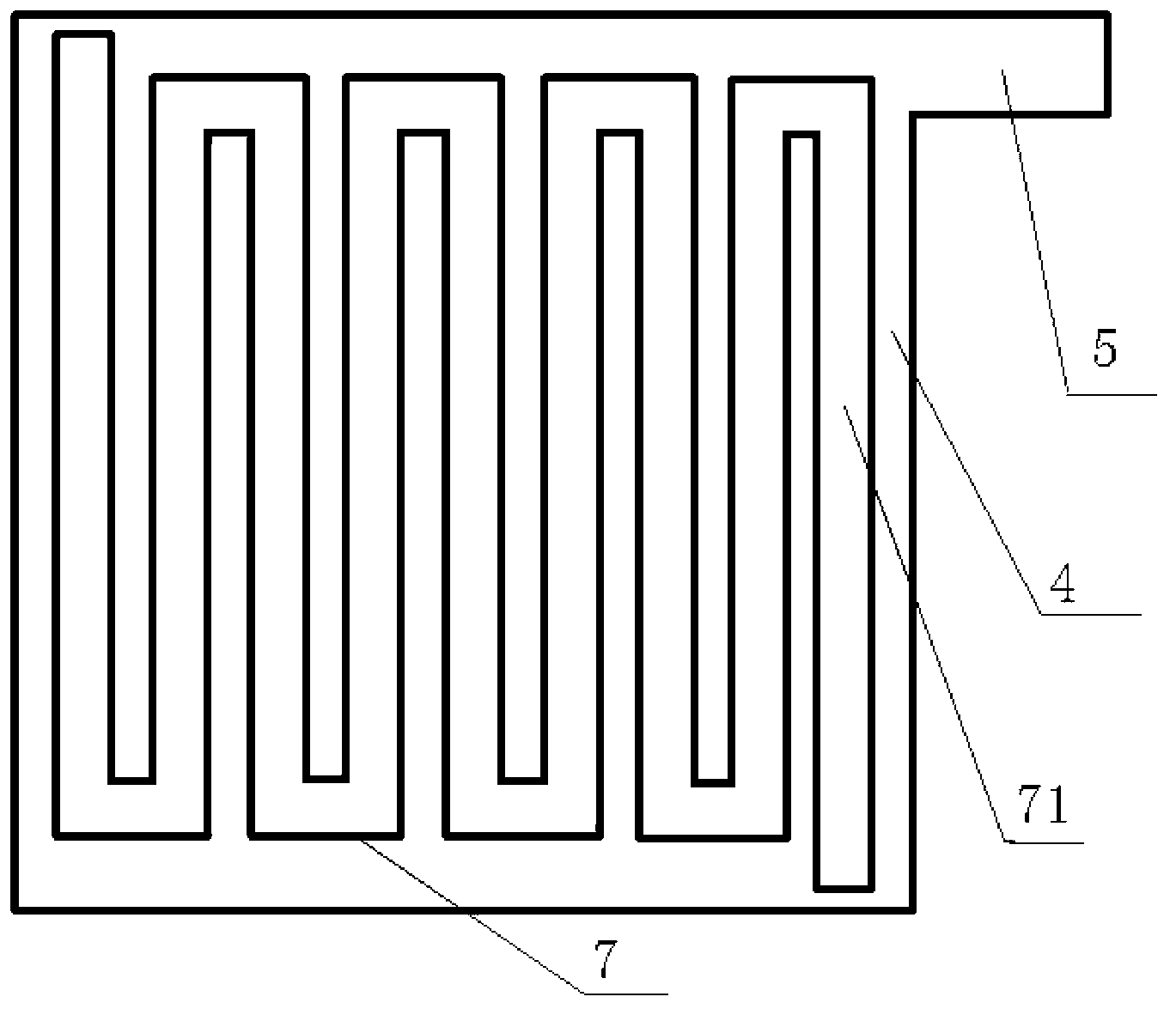

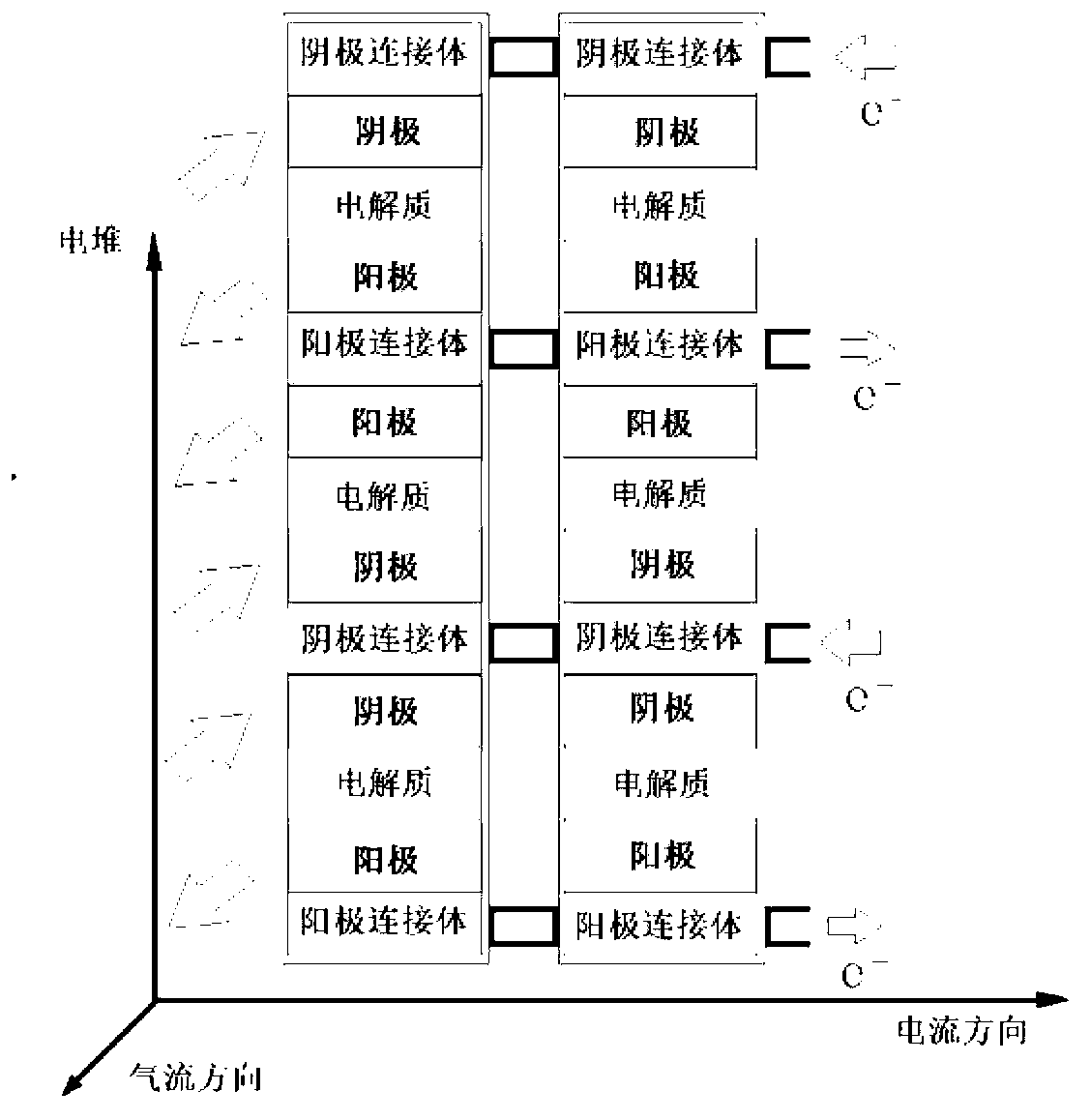

[0051] Such as Figure 1-2 as shown, An IT-SOFC battery stack alloy connector, The alloy connector is suitable for a battery stack that is vertically stacked by a plurality of flat single cells. The flat battery includes an anode 1, a solid oxide electrolyte 6 and a cathode 2. Any flat single cell is placed opposite to the same-sex electrode of an adjacent flat single cell. , that is, the anode 1 and the anode 1 of two adjacent flat single cells are placed opposite to each other, the cathode 2 is placed opposite to the cathode 2, the alloy connector 4 is arranged between the adjacent flat single cells, and the sealing is realized by the sealing material 3, Both the solid oxide electrolyte 6 and the sealing material 3 have four pores 9 for conducting fuel gas, the alloy connector 4 between the anode and the anode is an anode connector 41, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com