Parallel double-screw extruder unit

A twin-screw extruder and twin-screw extrusion technology, which is applied in the field of parallel twin-screw extruder units, can solve the problem of single material, low frequency of repeated use of materials, inability to meet the requirements of multiple raw materials and multiple forms of use, and suitable for customers. Higher requirements and other issues to achieve the effect of reducing labor intensity, reducing maintenance costs, and shortening maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

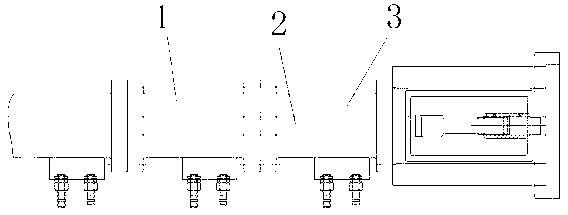

[0022] like figure 1 As shown, the parallel twin-screw extruder unit in this embodiment includes a preheating device, a torque distributor, a gear box, an extrusion system, and a cooling device. The extrusion unit includes a barrel 1, a mandrel 2, a thread Block 3, the cylinder body 1 is a split type; the screw rod is assembled by a threaded block 3 sleeved on the mandrel 2, the threaded block 3 adopts conventional threaded elements, and the inner bushing in the cylinder body 1 and the thread The shape of the block 3 is matched; the barrel composed of the barrel 1 is a split type, which is composed of several barrels 1; the torque distributor and the gear box are also building blocks. The twin-screw extruder is changed to counter-rotating or co-rotating; the screw grooves meshing with the co-rotating twin-screw are of a non-closed structure. The screw groove advances to the narrow gap below, and after being compressed to a certain extent, another screw is held up, and is tran...

Embodiment 2

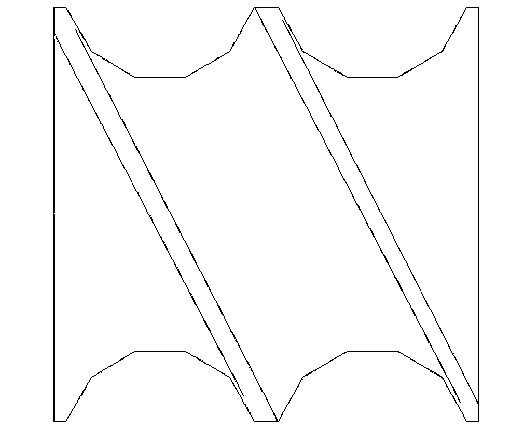

[0024] like figure 1 , 2 As shown, the thread block 3 used in the parallel twin-screw extruding unit in this embodiment is an S-shaped element with a length of 96 mm, including a preheating device, a torque distributor, a gear box, an extruding unit, and a cooling device. The discharge unit includes a barrel 1, a mandrel 2, and a threaded block 3; the screw is composed of a threaded block 3 sleeved on the mandrel 2, and the inner bushing in the barrel 1 matches the shape of the threaded block 3; The cylinder body 1 is an inlay type, which is composed of two parts, an inner and outer part, the inner part is an alloy inlaid sleeve, and the main body of the cylinder body is 38CrMoAlA. Usually, the cylinder bodies are fixed and connected by bolts, and the bolts can be disassembled one by one to be disassembled; The torque distributor and gear box are also of building block type, and the twin-screw extruder can be changed into counter-rotation or co-rotation by replacing the torqu...

Embodiment 3

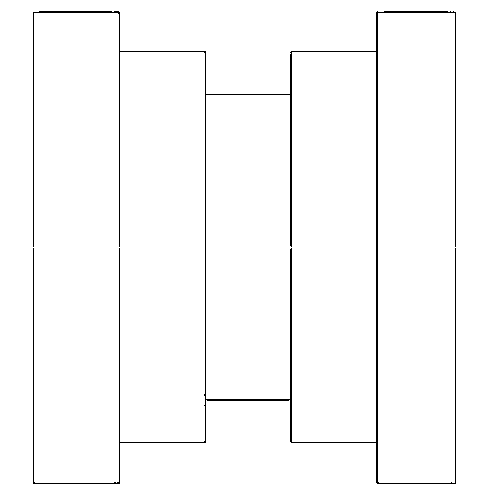

[0026] like figure 1 , 3 , 4, the thread block 3 used in the parallel twin-screw extruding unit described in this embodiment is a hexagonal prism element with a length of 56 mm, and the extrusion system includes a preheating device, a torque distributor, a gear box, an extrusion unit, Cooling device, traction device, meter counter, the extrusion unit includes a barrel 1, a mandrel 2, and a threaded block 3. It is characterized in that the barrel composed of the barrel 1 is a split type, consisting of several barrels 1; the screw is composed of threaded blocks 3 sleeved on the mandrel 2, and the inner bushing in the cylinder 1 matches the shape of the threaded blocks 3; the torque distributor and the gear box are also building blocks By replacing the torque distributor, the twin-screw extruder can be changed into counter-rotation or co-rotation; the gear box is connected with the single-screw extrusion system to form a single-screw extruder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com