Electro-hydraulic hybrid driving mine lifting device and control method thereof

A hybrid drive, hydraulic control valve technology, applied in elevators, transportation and packaging, sustainable buildings, etc., can solve the problems affecting the stable operation of the power grid, immature technology, and large power grid impact, and achieve improved safety and reliability and mature technology. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

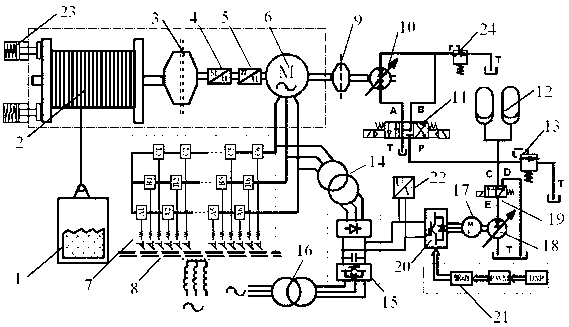

[0037] as attached figure 1 As shown, a mine hoist or winch that implements a hydraulic-electric hybrid drive according to the present invention includes a cage 1, a drum 2, a reducer 3, a torque sensor 4, a speed sensor 5, a hoisting motor 6, and a cascade type High-voltage frequency converter 7, phase-shifting transformer 8, gate control system 23, clutch 9, first hydraulic pump / motor 10, hydraulic control valve 11, hydraulic accumulator group 12, first safety valve 13, step-down transformer 14. Low-voltage inverter 15, step-up transformer 16, energy storage motor / generator 17, second hydraulic pump / motor 18, two-position three-way control valve 19, low-voltage inverter 20, energy storage motor / generator controller 21 , DC voltage sensor 22, the second safety valve 24, wherein:

[0038] The primary side of the phase-shifting transformer 8 is connected to the high-voltage AC power grid, and the secondary side of the phase-shifting transformer 8 is divided into three groups. ...

specific Embodiment approach 2

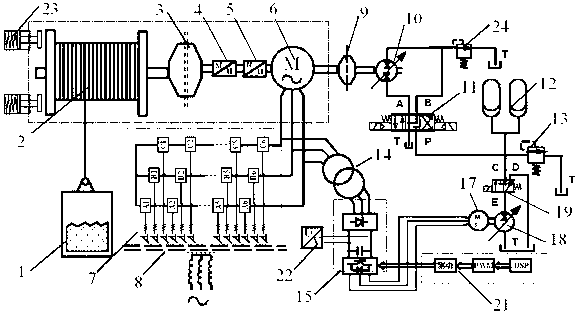

[0042] as attached figure 2As shown, Embodiment 2 is similar to Embodiment 1 in terms of working principle and structure. The difference is that the step-up transformer 16 and the low-voltage inverter 20 are eliminated, and the output end of the low-voltage frequency converter 15 is directly connected to the energy storage electric / The input end of motor 17 is connected, that is, when the power of the hoist is small, the function of feeding power to the AC grid may not be used.

specific Embodiment approach 3

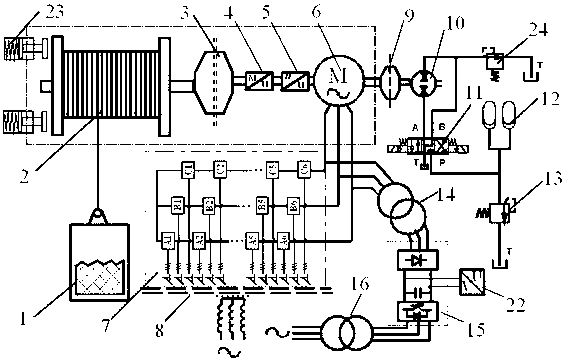

[0043] as attached image 3 As shown, Embodiment 3 is similar to Embodiment 1 in terms of working principle and structure, except that the energy storage electric motor / engine 17, the second hydraulic pump / motor 18, the two-position three-way control valve 19, and the low-voltage inverter are removed. 20 and energy storage motor / generator controller 21, retaining the independent feed unit composed of step-down transformer 14, step-up transformer 16, and low-voltage inverter 15; when the capacity of hydraulic accumulator group 12 is overloaded during operation , the lowering speed and deceleration process of the hoist can be controlled by feeding power to the high-voltage AC grid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com