Physical demulsifying and coalescing and oil-water separating method for oil-water emulsion under micro-electric field effect

A technology of oil-water emulsion and oil-water separation, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as high cost, high environmental requirements, and secondary pollution. Achieve the effect of small footprint and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

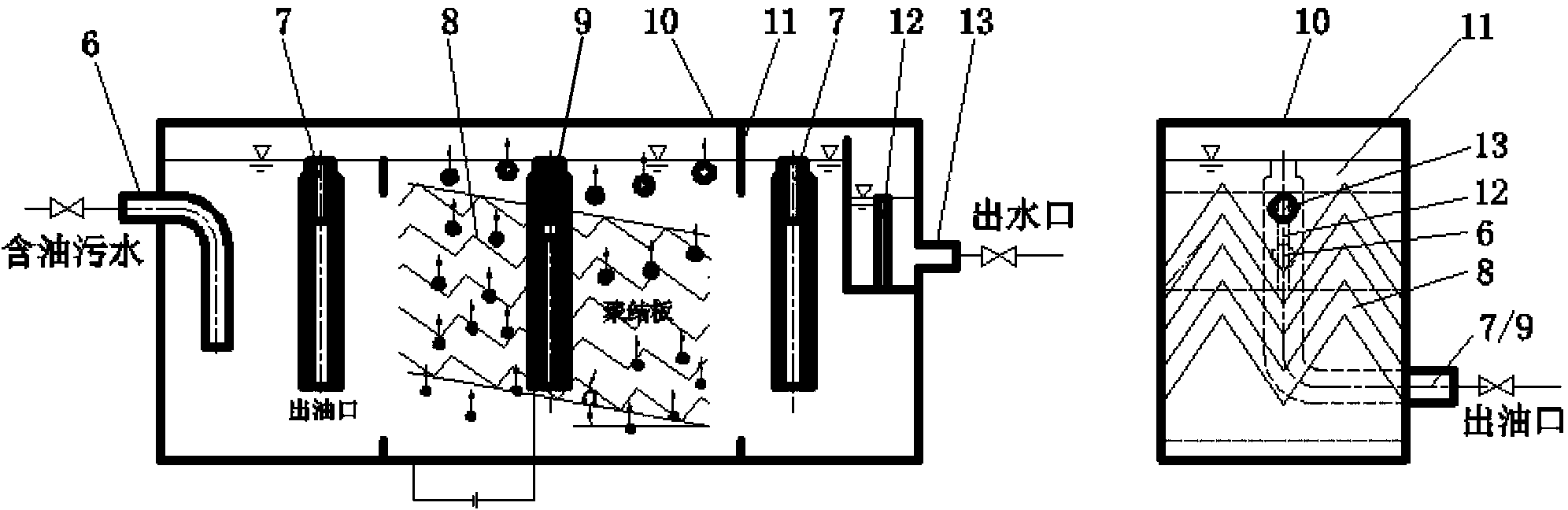

[0037] The present invention can be used in petroleum, food, machinery manufacturing, ship transportation and chemical industry containing emulsified oily sewage. This type of sewage cannot be separated from oil and water by simple gravity settlement and needs to be demulsified by adding a demulsifier.

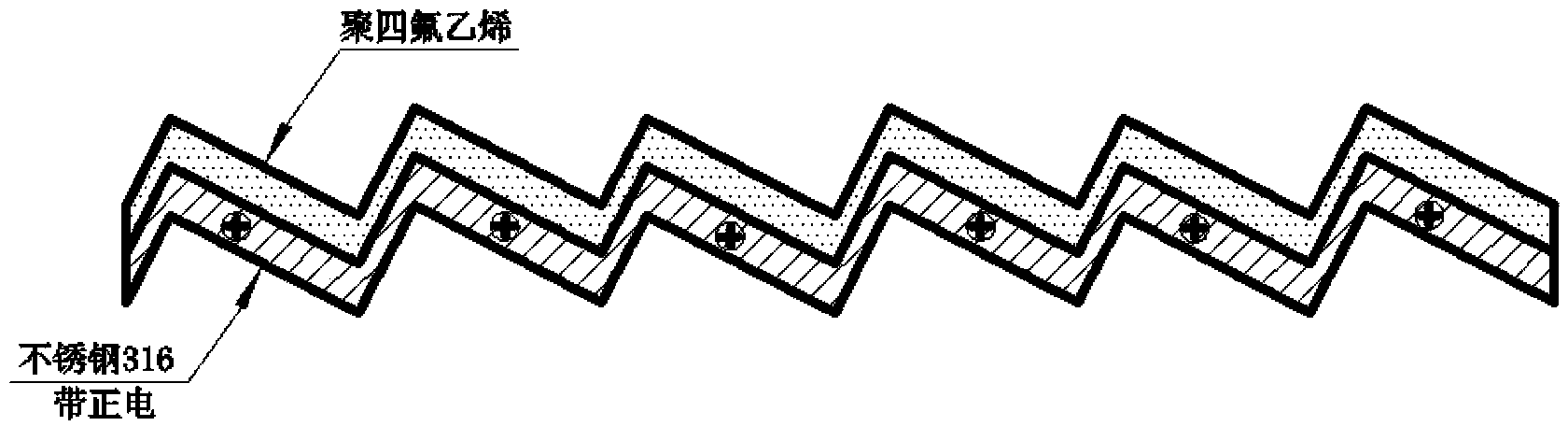

[0038] 6. The physical demulsification coalescence and oil-water separation method of oil-water emulsion under the action of micro-electric field as claimed in claim 1, characterized in that: the surface of the coalescing plate and the horizontal direction are at an angle of 5-15° to increase the amount of oily sewage The contact area with the coalescing plate increases the chance of collision between emulsified oil droplets and the lower surface of the coalescing plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com