Heat insulation coating

A coating and resin emulsion technology, applied in epoxy resin coatings, reflective/signal coatings, coatings, etc., can solve the problem of no patents and achieve the effect of easy painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

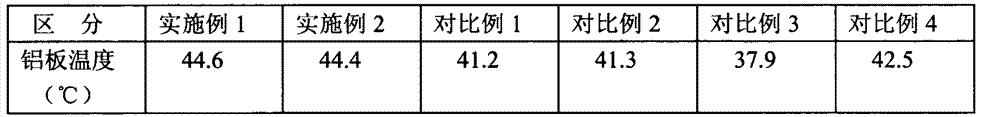

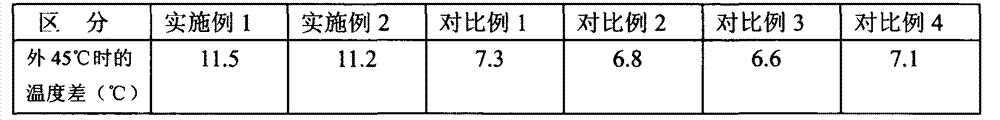

Embodiment 1

[0032] In the acrylic resin emulsion of 100 mass parts, adding average particle diameter is 20 mass parts of hollow glass microspheres of 80um, adding average particle diameter is 8 mass parts of 30um nephrite powder, adding average particle diameter is 35 mass parts of titanium dioxide of 25um, After adding 3 parts by mass of a dispersant and 1.5 parts by mass of a thickener, they were mixed, and then 15 parts by mass of water were added and fully stirred to obtain a heat-insulating coating. The specific gravity of the heat-insulating coating was 0.85.

Embodiment 2

[0034] In the acrylic resin emulsion of 100 mass parts, adding average particle diameter is 20 mass parts of hollow glass microspheres of 80um, adding average particle diameter is 30um nephrite powder 12 mass parts, adding average particle diameter is 35 mass parts of titanium dioxide of 25um, After adding 3 parts by mass of dispersant and 1.5 parts by mass of thickener, they were mixed, and then 15 parts by mass of water were added for thorough stirring to obtain a heat-insulating coating. The specific gravity of the heat-insulating coating was 0.87.

Embodiment 3

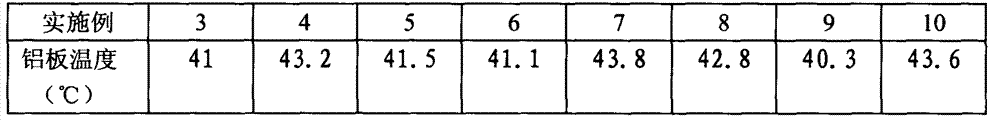

[0056] In 100 parts by mass of acrylic resin emulsion with a specific gravity of 1, add 15 parts by mass of hollow glass microspheres with an average particle size of 60um and a specific gravity of 0.1, and add 5 parts by mass of nephrite jade powder with an average particle size of 2um and a specific gravity of 2.9 , add 25 parts by mass of titanium dioxide with an average particle size of 2um and a specific gravity of 3.8, add 20 parts by mass of silicon acrylic emulsion, add 3 parts by mass of dispersant, add 0.5 parts by mass of thickener and mix, then add 15 parts by mass of water to carry out Thoroughly stir to obtain the thermal insulation coating, the specific gravity of the thermal insulation coating is 0.9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com