Production technology and method for preparing lump coal by use of coal dust and river mud

A production process and river mud technology, which is applied in the field of coal-fired processing technology, can solve problems such as surrounding environmental pollution, and achieve the effects of simple production process, low production cost, and abundant and easy-to-obtain raw material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

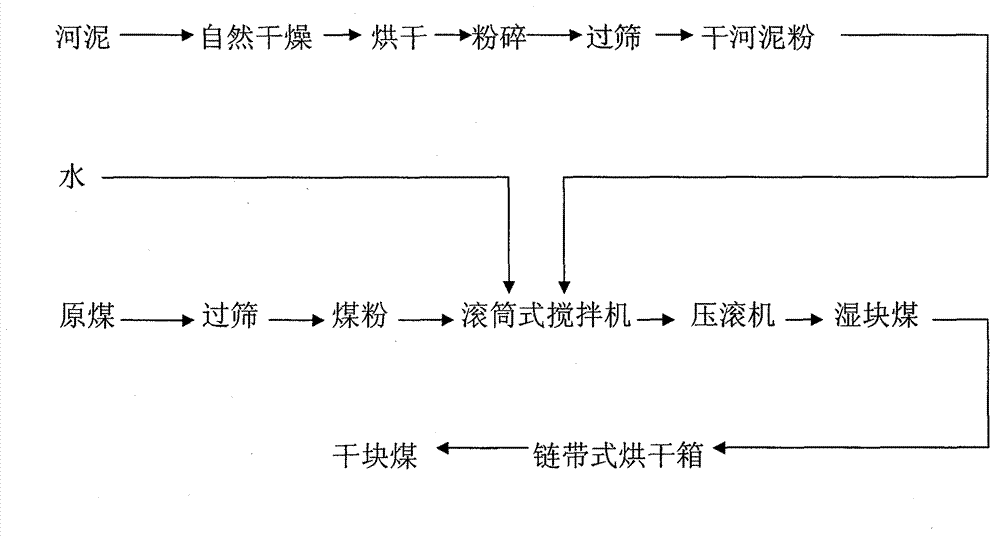

[0007] A production process and method for making lump coal from coal powder and river mud: firstly, sieve raw coal with a moisture content of less than 6%, screen out coal powder with a particle size below 3mm, and excavate the coal from the river The dry river mud powder obtained by natural drying, drying, crushing and sieving with a particle size of less than 3 mm is put into a drum mixer together for stirring, and the addition of the dried river mud powder is controlled at 30%. Add 12% water during the stirring process, stir evenly and then pour it into a roller press with a hopper to make wet lump coal, and then put the prepared wet lump coal in a chain-belt drying box for drying. The dried lump coal obtained after drying can be directly used in boilers for burning coal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com