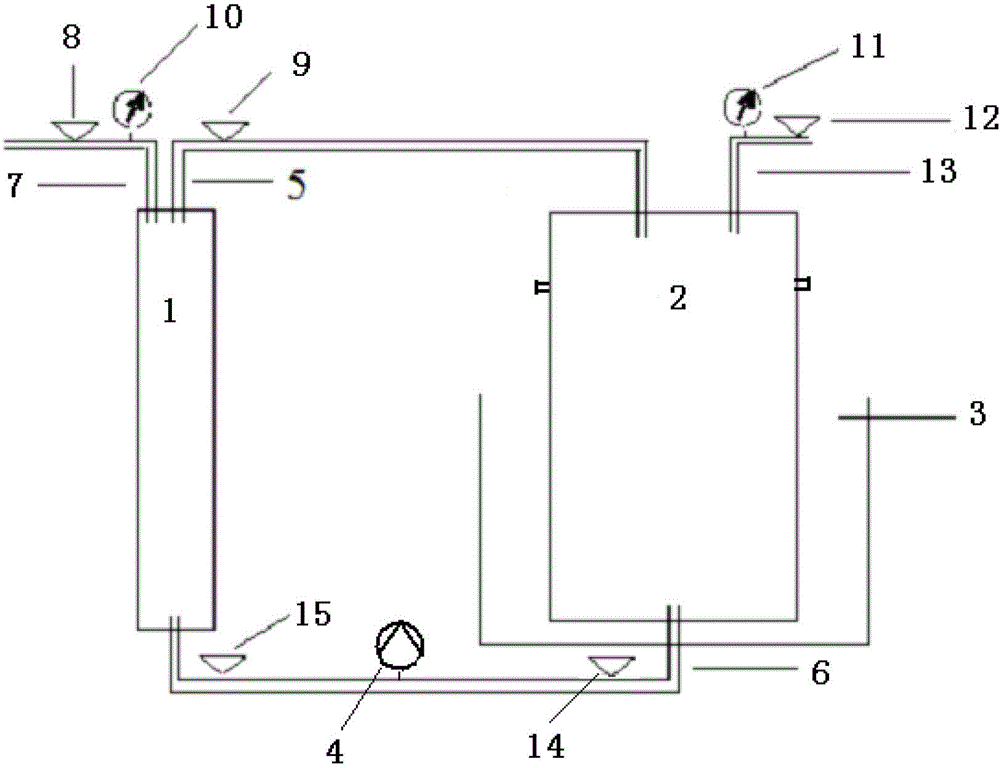

A high-pressure gas-liquid two-phase extraction cycle absorption device

A technology of absorption device and high-pressure gas, which is applied in the direction of sampling device, etc., can solve the problems of cumbersome sampling and analysis, complex structure of sampler, etc., and achieve the effect of fast and accurate sampling, simple structure and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

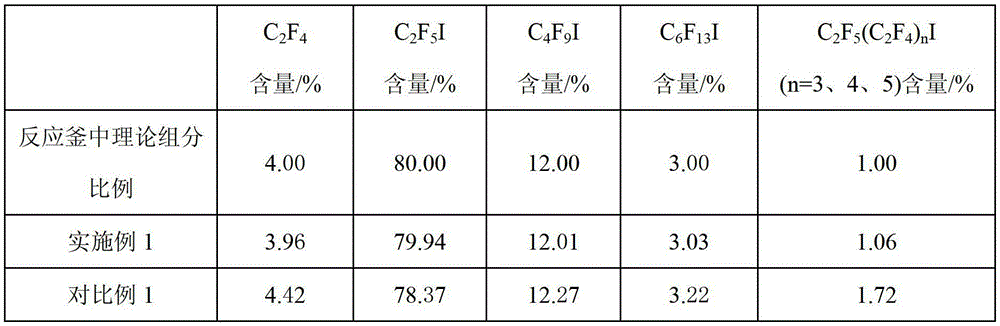

Embodiment 1

[0031] Buffer tank 1 is made of stainless steel with an inner cavity volume of 10mL; absorption tank 2 is made of stainless steel with an inner cavity volume of 50mL.

[0032] Connect the sampling pipe 7 to the sampling valve of the perfluoroalkyl iodide reaction kettle, open the first valve 8, and the sample enters the buffer tank 1 from the sampling pipe 7, and when the pressure shown by the first pressure gauge 10 is consistent with the pressure of the reaction kettle The first valve 8 can be closed; the third valve 9 can be opened to allow the sample to flow into the absorption tank 2 through the gas phase pipe 5 of the buffer tank; the temperature of the solvent acetone in the absorption tank 2 is controlled by the cooling tank 3 to be -18°C, and the components in the sample are passed through After the acetone is fully absorbed, open the fourth valve 14, the fifth valve 15, and start the circulation pump 4, so that the acetone flows into the buffer tank 1, and then into t...

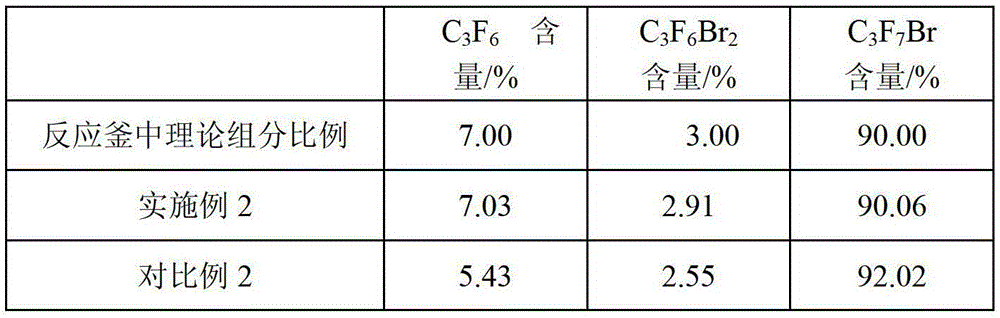

Embodiment 2

[0034] Buffer tank 1 is made of polytetrafluoroethylene with an inner cavity volume of 20mL; absorption tank 2 is made of polytetrafluoroethylene with an inner cavity volume of 150mL.

[0035] Connect the sampling pipe 7 with the sampling valve of the heptafluorobromopropane reaction kettle, open the first valve 8, and the sample enters the buffer tank 1 from the sampling pipe 7, and when the pressure displayed by the first pressure gauge 10 is consistent with the pressure of the reaction kettle Close the first valve 8; open the third valve 9, so that the sample flows into the absorption tank 2 through the buffer tank gas phase pipe 5; the temperature of the solvent ethyl acetate in the absorption tank 2 is controlled by the cooling tank 3 to be -20 ° C, and the components in the sample After being fully absorbed by ethyl acetate, open the fourth valve 14, the fifth valve 15, and start the circulation pump 4, so that the ethyl acetate flows into the buffer tank 1 and then into ...

Embodiment 3

[0037] Buffer tank 1 is made of stainless steel with an inner cavity volume of 15mL; absorption tank 2 is made of stainless steel with an inner cavity volume of 100mL.

[0038] Connect the sampling tube 7 to the sampling valve of the perfluoroalkyl ethyl iodide reactor, open the first valve 8, and the sample enters the buffer tank 1 from the sampling tube 7, when the pressure displayed by the first pressure gauge 10 is consistent with the reactor pressure The first valve 8 can be closed at the same time; the third valve 9 is opened to allow the sample to flow into the absorption tank 2 through the buffer tank gas phase pipe 5; the temperature of the solvent acetone in the absorption tank 2 is controlled by the cooling tank 3 to be -19 ° C, and the group in the sample After the acetone is fully absorbed, open the fourth valve 14, the fifth valve 15, and start the circulation pump 4, so that the acetone flows into the buffer tank 1, and then into the absorption tank 2 to achieve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com