Duplex piston ring-cylinder sleeve frictional wear test station

A friction and wear test, piston ring technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problems of complex loading device, complex installation and manufacturing, and complex manufacturing, so as to improve test performance, save installation space, improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

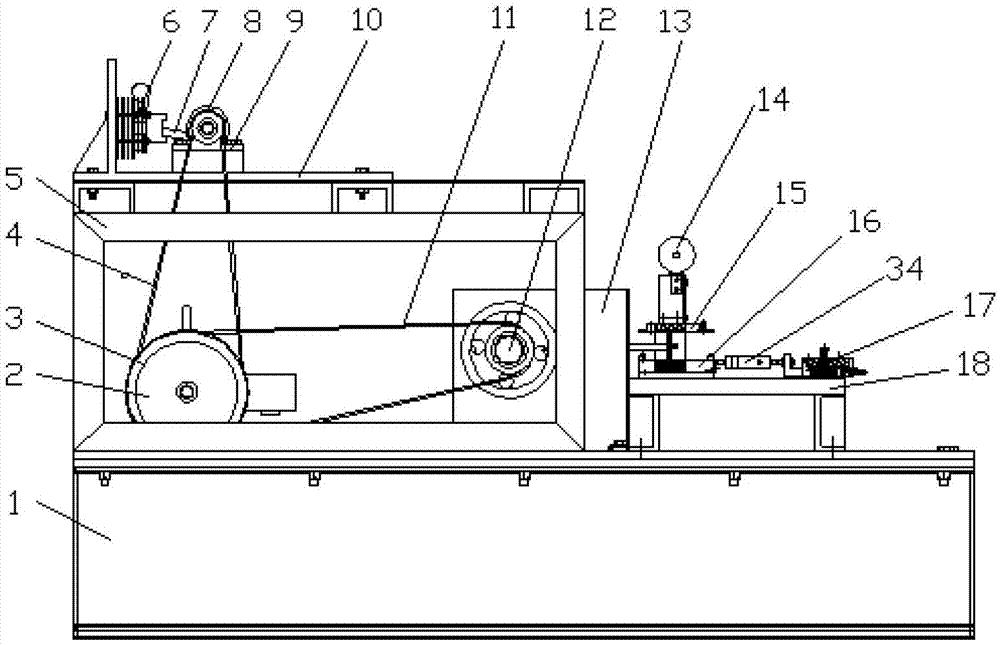

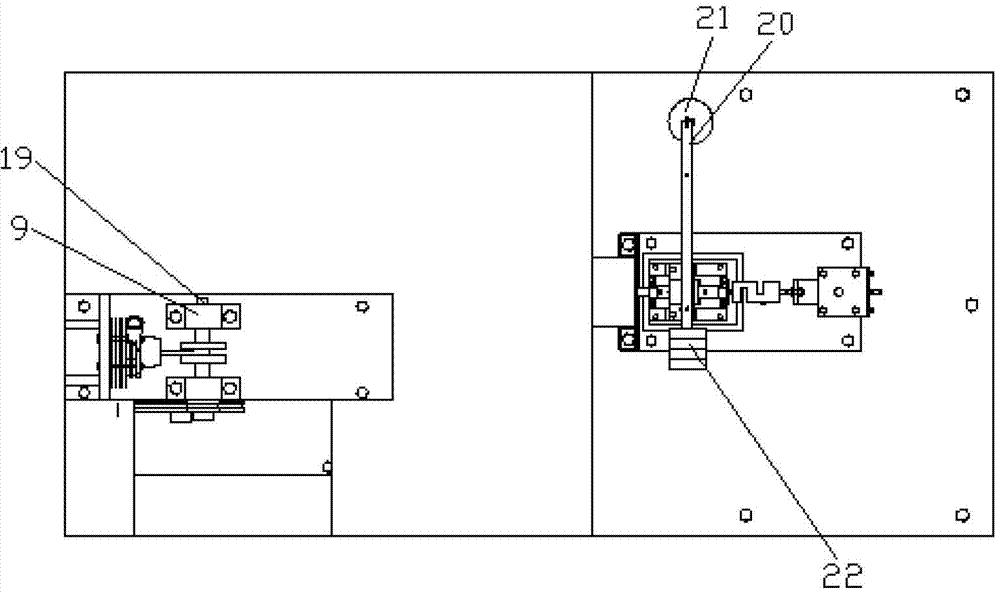

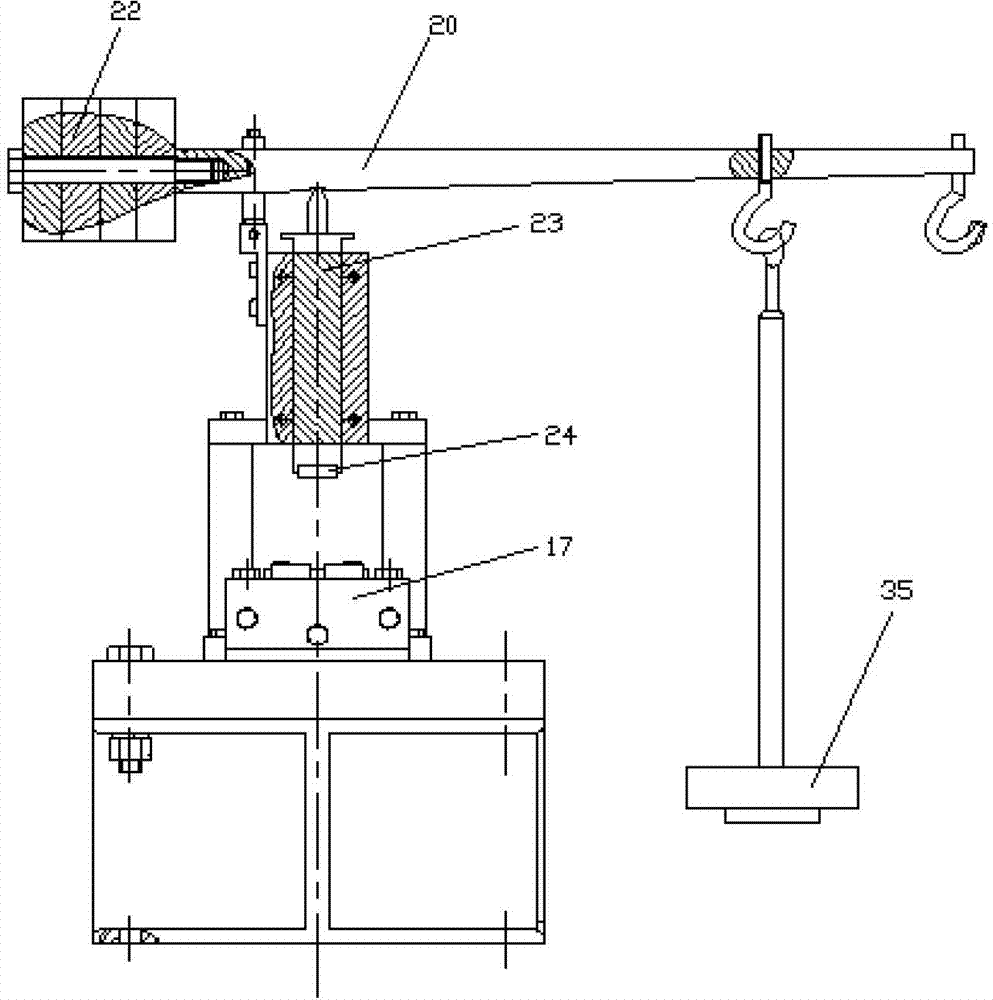

[0022] like figure 1 and figure 2 As shown, the friction and wear test bench is mainly composed of a power system, a transmission system, a loading system and a test system. The power is provided by the motor 2, and the motor 2 is fixed on the lower bracket 1; The second V-belt 11 is transmitted to the second small pulley 12, which drives the reformed diesel engine 13 to rotate. The diesel engine 13 changes the rotary motion into a linear motion, and connects the guide rod 30 to make the guide rod 30 do reciprocating motion. The guide rod 30 of the parts 31 and 29 reciprocates between the upper and lower cylinder liner test parts 24 and 25, and is manually loaded through the lever 20 and the weight plate 21; on the other hand, the power of the motor 2 is driven by the first The V belt 4 feeds the first small pulley 5, and the small pulley 5 drives the rotation of the crankshaft 19, and the crankshaft 19 drives the piston 33 to reciprocate in the piston cylinder 6 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com