Preparation method of heteropolytungstate/ carbon nano-tube/chitosan ternary composite film modified electrode

A technology of heteropolytungstate and carbon nanotubes is applied in the direction of material analysis, measurement device and instrument by electromagnetic means to achieve the effects of stabilizing electrical signals, improving sensitivity and stability, and reducing memory effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

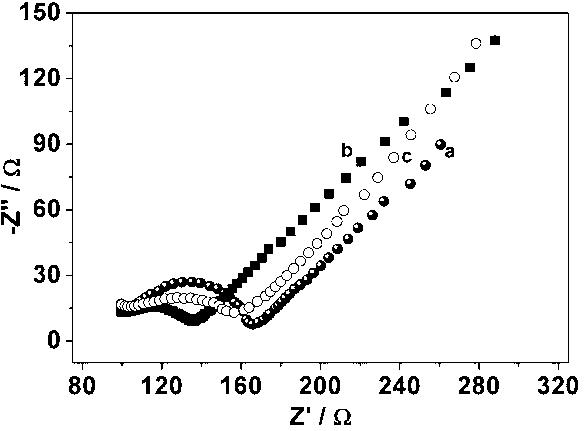

[0016] A preparation method of heteropolytungstate / carbon nanotube / chitosan ternary composite film modified electrode, the specific steps are as follows:

[0017] 1. Treatment of glassy carbon electrodes: use 1.0, 0.3 and 0.05 μm-Al 2 o 3 Polish with polishing powder, rinse with distilled water, then ultrasonically clean with 1:1 nitric acid, acetone and pure water, and dry in the air;

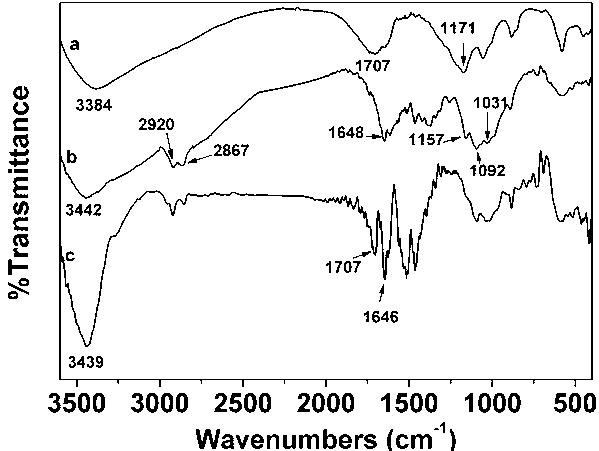

[0018] 2. Weigh 10 mg chitosan and dissolve in 10 ml, 0.1 mol / L acetic acid solution, take 5 mg acidified carbon nanotubes in 10 ml, 0.1 mol / L acetic acid solution, ultrasonically disperse for 15 minutes, and dissolve the above The two solutions were mixed and ultrasonicated for 30 minutes to obtain a carbon nanotube-chitosan suspension;

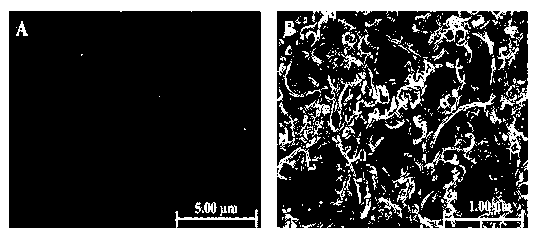

[0019] 3. Take 6 μl of the suspension and drop it on the surface of the glassy carbon electrode, and dry it at room temperature for 2 hours. In order to form a uniform carbon nanotube-chitosan composite film on the surface of the glassy carbon electrode, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com