Online sipping detection system for integrity detection for fuel element cladding in nuclear power plant

An integrity detection and fuel element technology, applied in nuclear power generation, nuclear engineering, nuclear reactor monitoring, etc., can solve the problems of many intermediate processes, inaccuracy, and cumbersome detection methods, so as to reduce errors, reduce operating space, and improve measurement. The effect of analytics level and automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

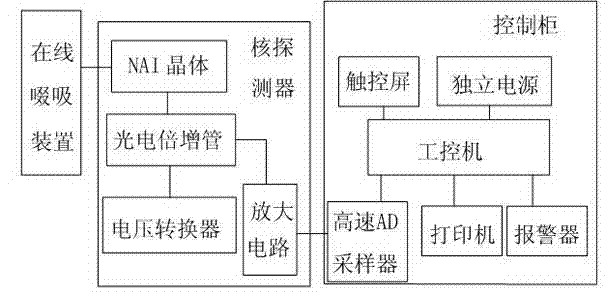

[0015] like figure 1 As shown, the online sipping detection system for nuclear power plant fuel element cladding integrity detection of the present invention includes an online sipping device, the output gas of the online sipping device is connected to a nuclear detector, and the output end of the nuclear detector is connected to a control cabinet; Wherein the nuclear detector includes a voltage converter, the output end of the voltage converter is connected to the photomultiplier tube, the output end of the photomultiplier tube is connected to the amplifying circuit, and the output end of the amplifying circuit is connected to the amplifying circuit of the control cabinet; the control cabinet includes an industrial computer , the output end of the amplification circuit is connected to the high-speed AD sampler, the output end of the high-speed AD sampler is connected to the industrial computer, and a touch screen is connected to the industrial computer, the industrial computer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com