Positive electrode for non-aqueous electrolyte secondary battery, non-aqueous electrolyte secondary battery and battery module

A non-aqueous electrolyte, secondary battery technology, applied in non-aqueous electrolyte storage batteries, secondary batteries, battery electrodes, etc., can solve the problems of slow lithium ion insertion/release speed, high charge transfer resistance, increased overvoltage, etc. To achieve the effect of improving the charging and discharging speed, improving the charging and discharging characteristics, and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

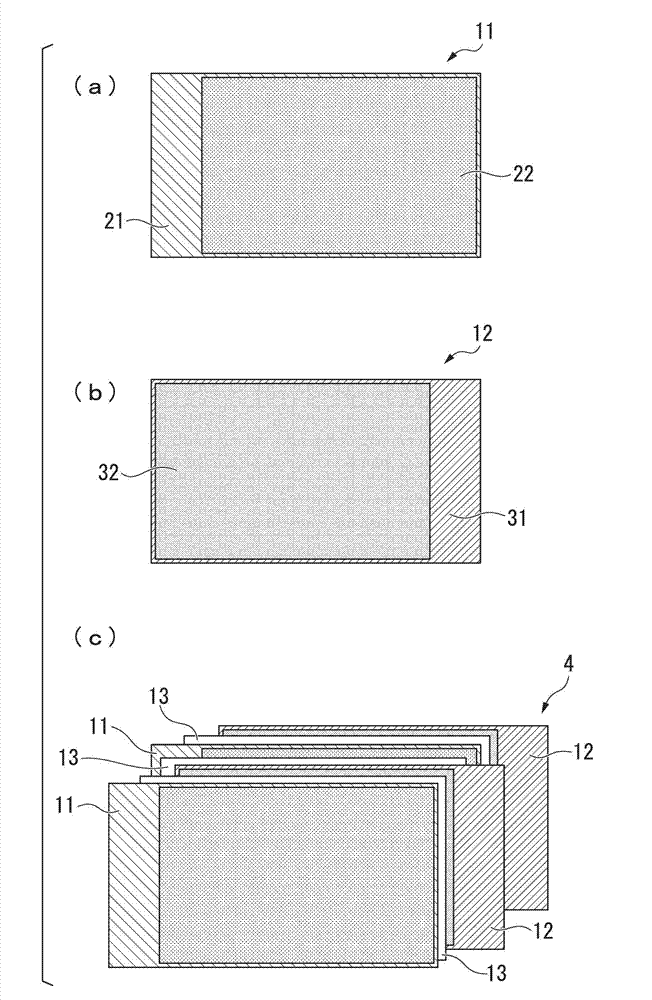

[0133] LiFePO with a carbonaceous film coverage of 100% and a primary particle size of 0.1 μm to 2 μm 4 The agglomerate of particles (manufactured by Sumitomo Osaka Cement) was used as the positive electrode active material, acetylene black was used as the conductive agent, and polyvinylidene fluoride (PVdF) was used as the binder, weighed by 100:5:7 (parts by mass), and Acetylene black and polyvinylidene fluoride (PVdF) were charged into N-methyl-2-pyrrolidone (NMP) in a kneader, and stirred / kneaded. Next, the above-mentioned LiFePO was put into the obtained mixture 4 The pellets were kneaded by a kneader at a rotation speed of 100 rpm for 90 minutes to prepare a slurry.

[0134] Next, the slurry was coated on an aluminum foil with a coater, dried, and then pressed with a roll press to form a positive electrode active material layer with a thickness of 100 μm on the aluminum foil, which was used as the positive electrode of Example 1.

[0135] Next, graphite is used as the ...

Embodiment 2

[0137] The positive electrode and the secondary battery of Example 2 were fabricated in accordance with Example 1 except that the kneader was kneaded at a rotation speed of 100 rpm for 150 minutes.

Embodiment 3

[0154] Use the following raw materials to make positive electrodes.

[0155] Positive electrode active material: LCP420, TU-4 (trade name: manufactured by Sumitomo Osaka Cement Co., Ltd.)

[0156] Material ratio of positive electrode active material layer (mass parts)

[0157] Positive electrode active material: acetylene black: PVdF=100:5:7

[0158] The above-mentioned positive electrode active material is that the surface of primary particles of olivine-type lithium iron phosphate is coated with a carbon coating at a coverage area ratio of almost 100%, and the primary particles of the carbon coating are bonded to each other to form olivine secondary particles. Agglomerates of stone-type lithium iron phosphate particles. When the thickness of the positive electrode active material layer formed by applying and drying the slurry is rolled to adjust the thickness, the secondary particles are disintegrated and scattered due to the rolling, and basically become primary granular ol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Filling density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com