Graphite carbon/metal nitride composite nanotube array and preparation method and application thereof

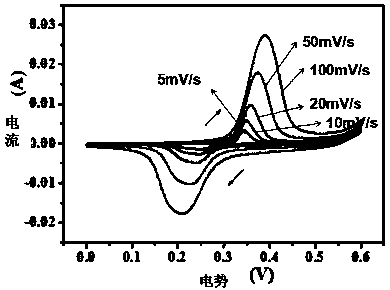

A nanotube array and nanorod array technology are applied in the field of graphitic carbon/metal nitride composite nanotube arrays and their preparation to achieve the effects of improving charge and discharge speed, excellent charge and discharge speed and energy density, and a simple and efficient preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A graphitic carbon / metal nitride composite nanotube array, composed of graphitic carbon and metal nitride cobalt nitride to form a graphitic carbon / metal nitride double-walled nanotube array, the tube of the graphitic carbon / metal nitride double-walled nanotube array The diameter is 600nm, the length is 10μm, the thickness of graphite carbon wall is 50nm, and the thickness of cobalt nitride wall is 250nm.

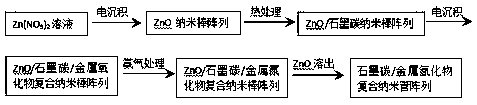

[0043] The above graphitic carbon / metal nitride composite nanotube array is prepared by the electrodeposition method guided by the ZnO template method according to the following steps:

[0044] S1: ZnO nanorod arrays were immersed in 3mol / L glucose solution for 60 minutes, and then heat-treated at 1000°C for 3 hours under vacuum conditions to obtain ZnO / graphitic carbon composite nanorod arrays;

[0045] S2: Using the ZnO / graphite carbon composite nanorod array as the cathode, at 1.0mol / L Co(NO 3 ) 2 In solution, at a current density of 3.0mA / cm 2 Electrodepositio...

Embodiment 2

[0054] A graphitic carbon / metal nitride composite nanotube array, composed of graphitic carbon and metal nitride cobalt nitride to form a graphitic carbon / metal nitride double-walled nanotube array, the tube of the graphitic carbon / metal nitride double-walled nanotube array The diameter is 600nm, the length is 10μm, the thickness of graphite carbon wall is 60nm, and the thickness of cobalt nitride wall is 120nm.

Embodiment 3

[0056] A graphitic carbon / metal nitride composite nanotube array, composed of graphitic carbon and metal nitride cobalt nitride to form a graphitic carbon / metal nitride double-walled nanotube array, the tube of the graphitic carbon / metal nitride double-walled nanotube array The diameter is 1000nm, the length is 10μm, the thickness of the graphite carbon wall is 150nm, and the thickness of the cobalt nitride wall is 200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com