Preparation method of carbon nano-tube super capacitor

A technology of supercapacitors and carbon nanotubes, which is applied in the manufacture of hybrid/electric double-layer capacitors, etc., can solve the problems of chemical batteries polluting the environment, short service life, and poor temperature characteristics, and achieve high energy density, low raw material cost, and quality light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

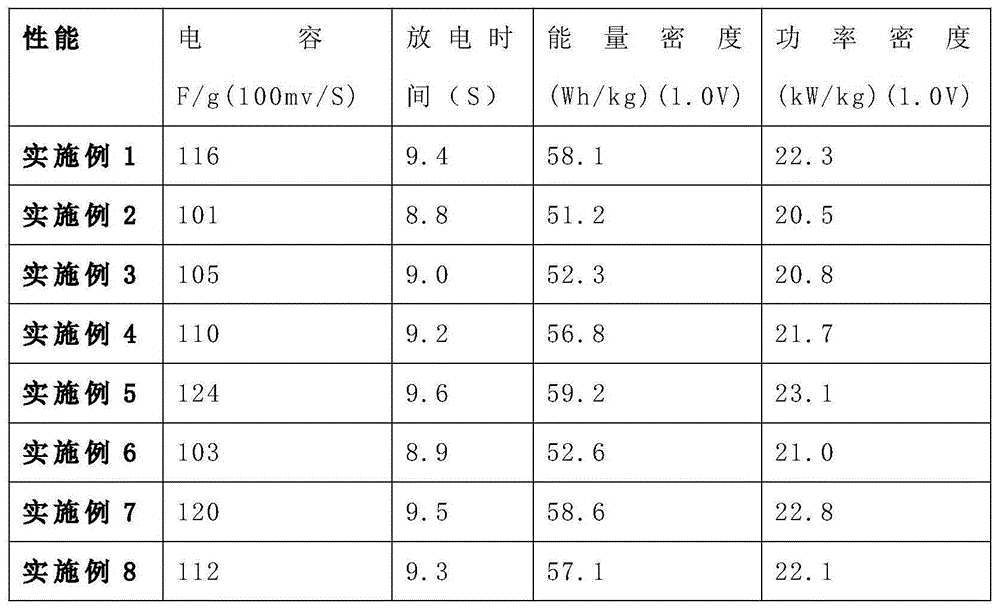

Examples

Embodiment 1

[0028] A carbon nanotube yarn supercapacitor, its preparation method is as follows:

[0029] A platinum wire with a diameter of 15 microns and a carbon nanotube yarn with a diameter of 20 microns are intertwined to form a double-ply yarn (denoted as Pt / CNT-1520); 0.2g aniline, 0.3g ammonium persulfate, 16g high chlorine After mixing acid, 16g of deionized water and 4g of absolute ethanol evenly, stick a Pt / CNT-1520 double-ply yarn with a length of about 15 cm on a support and put it into the above mixed solution. The reaction was stirred for 48 hours, and polyaniline was grown in situ on the surface of the Pt / CNT-1520 double-ply yarn to obtain a composite yarn (denoted as Pt / CNT / PANI-1520A), and then the composite yarn was carefully taken out with tweezers, and deionized Rinse the surface with water, and dry it in vacuum to remove water; soak two dried Pt / CNT / PANI-1520A composite yarns in polyvinyl alcohol-phosphoric acid sol for 1 minute, slowly pull out, and the surface of t...

Embodiment 2

[0032] A carbon nanotube yarn supercapacitor, its preparation method is as follows:

[0033] A gold wire with a diameter of 12 microns and a carbon nanotube yarn with a diameter of 15 microns are intertwined to form a double-ply yarn (referred to as Au / CNT-1215); 0.2g aniline, 0.5g ammonium persulfate, 24g high chloride After mixing acid, 10g deionized water and 6g absolute ethanol evenly, stick an Au / CNT-1215 double-ply yarn with a length of about 15 cm on a support and put it into the above mixed solution, and keep it at -15°C The reaction was stirred for 40 hours, and polyaniline was grown in situ on the surface of the Au / CNT-1215 double-ply yarn to obtain a composite yarn (referred to as Au / CNT / PANI-1215A), and then the composite yarn was carefully taken out with tweezers, and deionized Rinse the surface with water, and vacuum dry to remove the water; soak two dried Au / CNT / PANI-1215A composite yarns in the polyvinyl alcohol-phosphate sol for 1 minute, slowly pull out, and ...

Embodiment 3

[0036] A carbon nanotube yarn supercapacitor, its preparation method is as follows:

[0037] A silver wire with a diameter of 50 microns and a carbon nanotube yarn with a diameter of 20 microns are intertwined to form a double-ply yarn (referred to as Ag / CNT-5020); 0.2g aniline, 0.4g ammonium persulfate, 30g high chloride After mixing acid, 30g deionized water and 8g absolute ethanol evenly, stick a Ag / CNT-5020 double-ply yarn with a length of about 15 cm on a support and put it into the above mixed solution. The reaction was stirred for 36 hours, and polyaniline was grown in situ on the surface of the Ag / CNT-5020 double-ply yarn to obtain a composite yarn (referred to as Ag / CNT / PANI-5020A), and then the composite yarn was carefully taken out with tweezers, and deionized Rinse the surface with water, and vacuum dry to remove moisture; soak two dried Ag / CNT / PANI-5020A composite yarns in polyvinyl alcohol-phosphoric acid sol for 1 minute, slowly pull out, and the surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com