Method for gaseous-phase catalysis-free continuous synthesizing of 3-methyl-3-butenyl-1-alcohol

A butene-based, continuous process technology, applied in organic chemistry, reduction preparation of oxygen-containing functional groups, etc., can solve problems such as blockage of pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1 (pre-depolymerization of paraformaldehyde )

[0020] The pre-depolymerization of paraformaldehyde is at 0.1M 3 carried out in a stirred and jacketed atmospheric tank reactor. First replace the reactor with N2 and then add 20Kg of methanol and 0.4Kg of TEA. Turn on the stirrer, slowly add 20Kg of 96wt%~97wt% paraformaldehyde, and pass 80°C hot water into the jacket to keep the liquid phase temperature in the kettle at 40~60°C for about 40~100min. There was no solid precipitate in the kettle. This liquid was put into an autoclave and pressurized with nitrogen to prepare for the synthesis reaction.

[0021] The formaldehyde content of the pre-depolymerization liquid is 46wt%-48wt%, and the rest is methanol and a small amount of water.

Embodiment 2

[0022] Example 2: (Synthesis of 3-methyl-3-butenyl-1-ol from isobutene and formaldehyde)

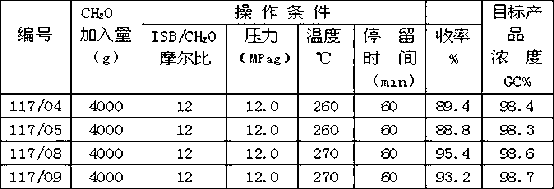

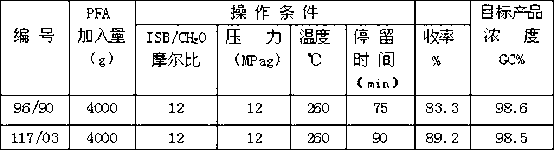

[0023] Mix fresh isobutene and recovered isobutene, send it to the inlet of the high pressure pump at a pressure of 0.2-0.3MPag, pressurize it to 13.0MPag, and pass through the steam heater and heat exchanger in turn heat medium) and an electric heater to raise the temperature to 270-290°C and send it into the synthesis reactor. The reactor pressure is 12-13.5MPag. The paraformaldehyde pre-depolymerization solution prepared in example 1 is also delivered to the plug flow reactor by nitrogen pressure, and the pre-depolymerization solution is evaporated and vaporized immediately in the reactor, and the quantity of two kinds of feeds is adjusted so that isobutylene and The molar ratio of formaldehyde was 12:1 and the retention time was 1 hour. The temperature in the reactor is 260°C and 270°C. The gas at the outlet of the reactor exchanges heat with the incoming isobutylene, and the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com