A wear-resistant alloy and its application in grinding tiles

A wear-resistant alloy and cemented carbide technology, which is applied to wear-resistant alloys and their application in coal mill grinding discs, can solve the problems of low comprehensive properties such as strength, hardness, toughness and service life, and achieve internal and external hardness. The effect of uniformity, increased efficiency, and improved tissue stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] In this embodiment, by weight percentage, the chemical composition of the wear-resistant alloy is:

[0057] C0.33; Si1.0; Mn0.9; P0.035; S0.024; Cr23; Cu1.15; Mo2;

[0058] In this embodiment, the heat treatment process of the wear-resistant alloy includes the following steps:

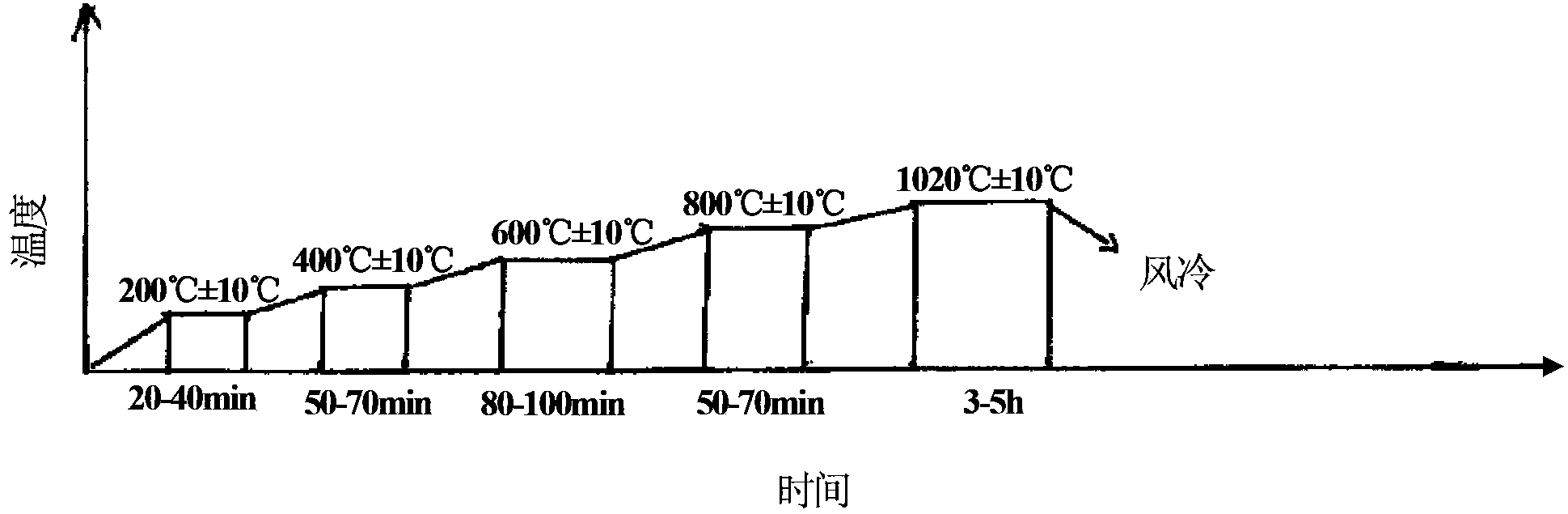

[0059] 1. For normalizing, the temperature is gradually increased in stages and then rapidly cooled after heat preservation:

[0060] 200℃±10℃ for 30 minutes;

[0061] 400℃±10℃ for 60 minutes;

[0062] 600℃±10℃ for 90 minutes;

[0063] 800℃±10℃ for 60 minutes;

[0064] 1020℃±10℃ for 4 hours;

[0065] Air cooling to room temperature by means of fan blowing;

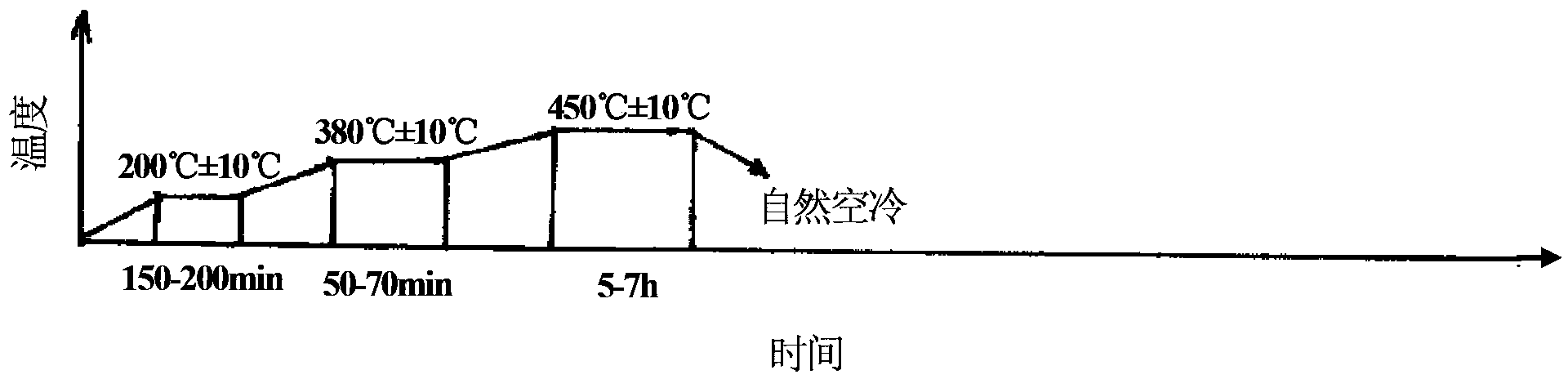

[0066] 2. Tempering, natural cooling after heat preservation in stages with gradually rising temperature:

[0067] 200℃±10℃ for 180 minutes;

[0068] 380℃±10℃ for 60 minutes;

[0069] 450℃±10℃ for 6 hours;

[0070] Cool naturally to room temperature.

[0071] In this embodiment, after adopting the described alloy composition and h...

Embodiment 2

[0075] In this embodiment, by weight percentage, the chemical composition of the wear-resistant alloy is:

[0076] C0.32; Si1.1; Mn0.8; P0.028; S0.033; Cr24; Cu1.1; Mo3; Al0.1; V0.6; B0.02; .

[0077] In this embodiment, the heat treatment process of the wear-resistant alloy includes the following steps:

[0078] 1. For normalizing, the temperature is gradually increased in stages and then rapidly cooled after heat preservation:

[0079] 200℃±10℃ for 20 minutes;

[0080] 400℃±10℃ for 70 minutes;

[0081] 600℃±10℃ for 80 minutes;

[0082] 800℃±10℃ for 70 minutes;

[0083] 1020℃±10℃ for 3 hours;

[0084] Air cooling to room temperature by means of fan blowing;

[0085] 2. Tempering, natural cooling after heat preservation in stages with gradually rising temperature:

[0086] 200℃±10℃ for 150 minutes;

[0087] 380℃±10℃ for 70 minutes;

[0088] 450℃±10℃ for 5 hours;

[0089] Cool naturally to room temperature.

[0090] In this embodiment, after adopting the described a...

Embodiment 3

[0094] In this embodiment, by weight percentage, the chemical composition of the wear-resistant alloy is:

[0095] C0.35; Si0.9; Mn1.0; P0.035; S0.026; Cr22; Cu1.2; Mo1; Al0.2; V0.4; B0.04; .

[0096] In this embodiment, the heat treatment process of the wear-resistant alloy includes the following steps:

[0097] 1. For normalizing, the temperature is gradually increased in stages and then rapidly cooled after heat preservation:

[0098] 200℃±10℃ for 40 minutes;

[0099] 400℃±10℃ for 50 minutes;

[0100] 600℃±10℃ for 100 minutes;

[0101] 800℃±10℃ for 50 minutes;

[0102] 1020℃±10℃ for 5 hours;

[0103] Air cooling to room temperature by means of fan blowing;

[0104] 2. Tempering, natural cooling after heat preservation in stages with gradually rising temperature:

[0105] 200℃±10℃ for 200 minutes;

[0106] 380℃±10℃ for 50 minutes;

[0107] 450℃±10℃ for 7 hours;

[0108] Cool naturally to room temperature.

[0109] In this embodiment, after adopting the described ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com