Design method for composite target for magnetron sputtering

A composite target material and magnetron sputtering technology, which are applied in the field of magnetron sputtering technology and the preparation of inorganic compound functional thin films, can solve the problems of expensive and complex co-sputtering systems, achieve easy control and regulation, reduce preparation costs, and reduce the cost of thin films. The effect of uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

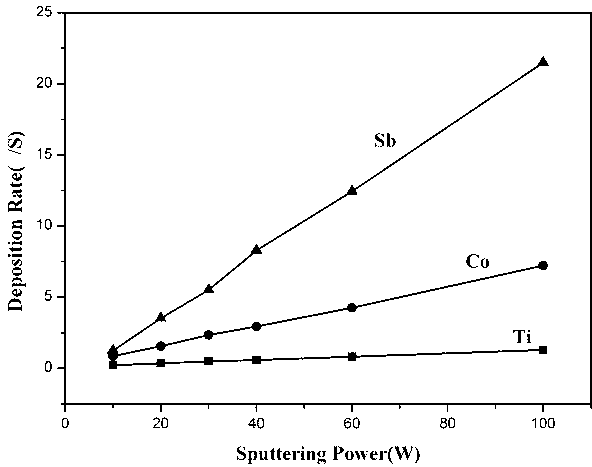

[0018] According to the design method of the composite target for magnetron sputtering of the present invention, firstly, the single substance thin film is prepared respectively by the magnetron sputtering method and its thickness is measured by a step meter to obtain the growth parameter curve of each target material, for example: Heusler compound semiconductor TiCoSb, fixed sputtering pressure and substrate temperature and other parameters, to obtain sputtering power-film thickness curve, such as figure 1 shown. Calculate the sputtering rate of each element under different power. The difference of sputtering rate of the three elements increases rapidly with the increase of sputtering power. Too high power is not conducive to the formation of stoichiometric TiCoSb thin films, while too low power deposition efficiency is low. Taking the two into consideration, the sputtering power can be selected as 20 W. According to this calculation, the angle ratio of the three elements ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com